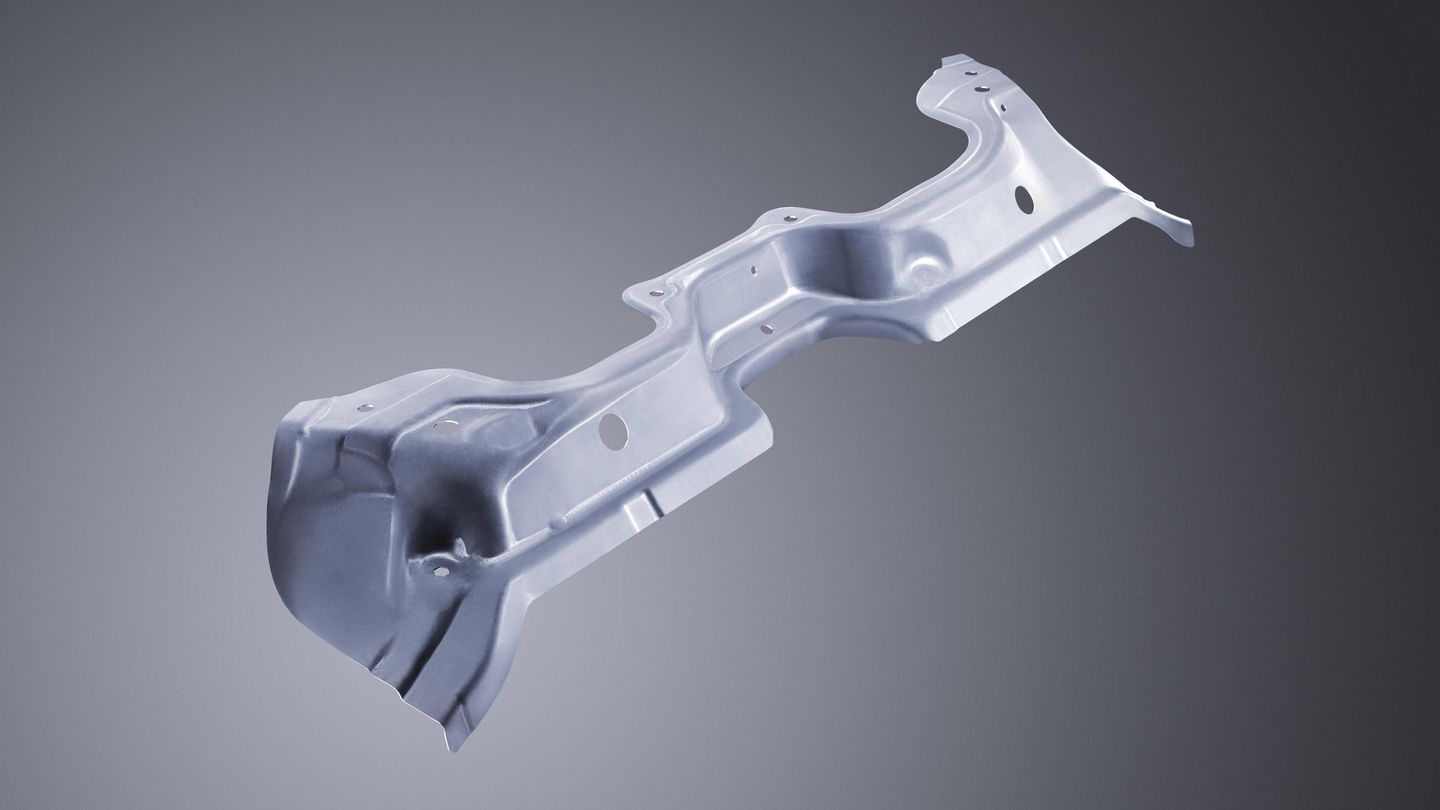

TruLaser Cell 8030

Productive high-end 3D laser cutting machine

The second generation TruLaser Cell 8030 once again sets the standard for the 3D cutting of hot-formed components. As a result of new developments and optimized details, it offers even greater production reliability, combined with arguably the highest productivity on the market. You can increase your profitability due to options such as the Smart Approach, Dynamic Level 2, or the rotary indexing table.

Kategori: 3D Laser

Options

Rotary indexing table

Is the process step of manual loading and unloading creating a bottleneck in your production? The rotary indexing table helps by completely separating the loading and unloading areas. Alternatively, you can place a robot on the unloading side as a cost-effective partial automation option. This results in the shortest cycle times with only one employee, and you can produce parts much more productively. If your requirements change over time, you can change this option to a fully automated solution at any time.

MobileControl app

With the MobileControl app from TRUMPF you can operate and monitor your machines simply and flexibly as the app transmits the interface of the standard control panel onto the touch screen of your tablet PC. In addition to the static control panel, you therefore also have another option for monitoring and controlling your machine.

Smart Approach

The Smart Approach function optimizes and improves the approach behavior of the machine when the edge of the component is pierced. This patented process reduces cycle time by up to 9%, while ensuring maximum process reliability.

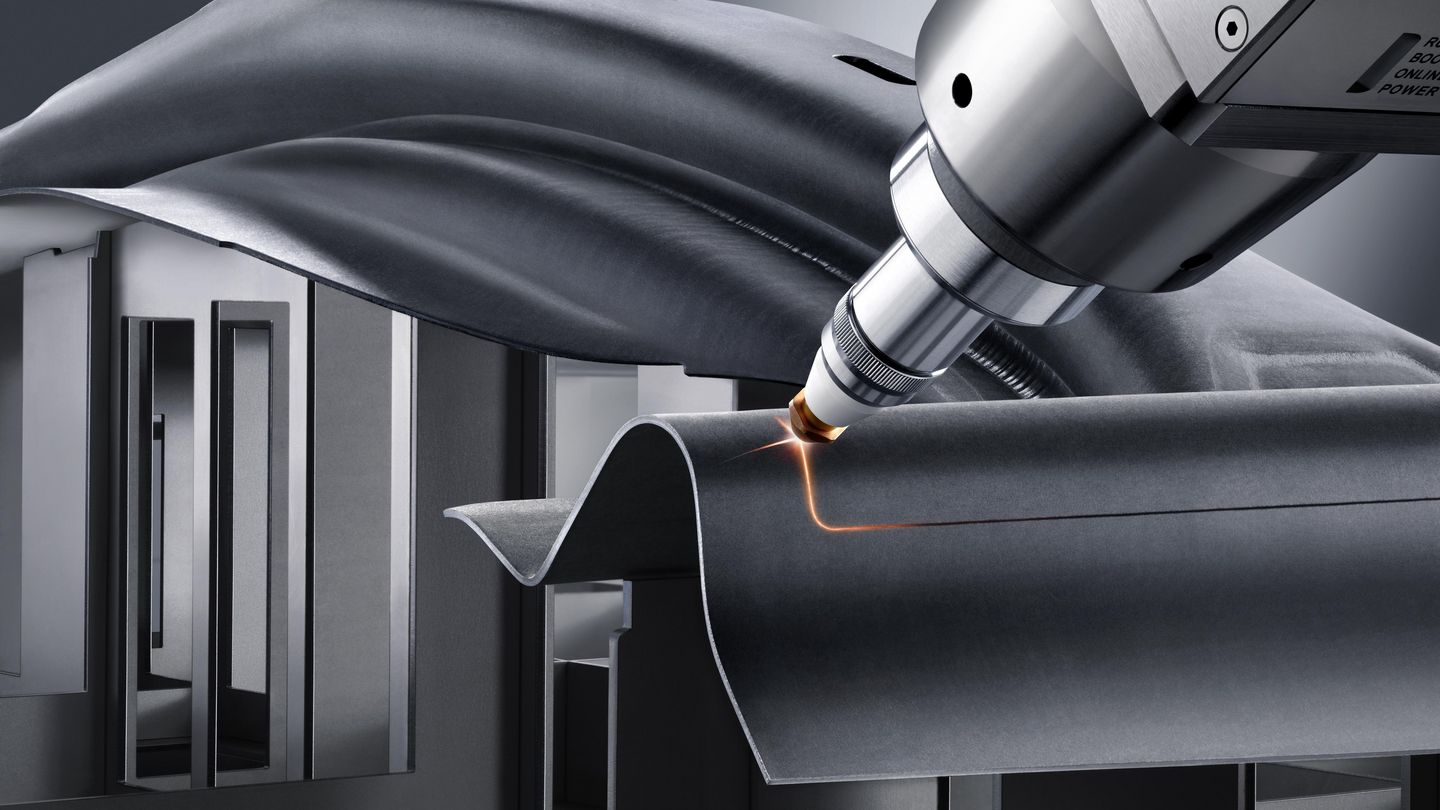

FocusLine

FocusLine enables the program-controlled setting of the focal position depending on the type of material and the material thickness. The position is adjusted using a mirror subject to water pressure, influencing the curvature of its surface.

ObserveLine Professional

Minor nozzle collisions can cause minimal incorrect positioning of the cutting optics, invisible to the operator. This results in increased rejects and associated costs. The ObserveLine Professional optical measuring procedure checks the positioning accuracy of the machine at regular, freely definable intervals, without the need for refitting and with virtually no effects on the cycle time. Incorrect positioning is detected and the number of rejects is reduced.

ObserveLine Comfort

There are various reasons as to why cutting slugs remain in the finished part. With the ObserveLine Comfort optical measuring process, you detect this error quickly since this option checks every contour for a complete cut. ObserveLine Comfort has several advantages compared to measurement using distance regulation. The process reduces the measuring time and you can even measure smaller hole diameters and angled punching slugs.

Smart Optics Setup

Smart Optics Setup is a fixture attached to the machine base unit which cuts test sheets and readjusts the machine. Implementation is even easier due to standardized macros, saving time and money.

FastLine

FastLine improves and optimizes the approach behavior of the machine during piercing for contour cutting. Depending on the type of material and the material thickness, as well as the number of contours to be processed, you can increase the productivity of your system by up to 60%.

Comfort processing time display

The Comfort processing time display ensures that you are perfectly informed at all times. It displays the remaining processing time of the component currently being processed, and provides additional information on the current status of the manufacturing job.

Automation interface

Depending on the degree of automation of your production system, you can choose between different interface options. The Basic option reliably provides signals for production planning systems. With the Comfort option, you can implement more simple automation options independently. The Professional option is well-suited for highly automated production.

For all three solutions, you can profit from complete documentation and future upgrades, ensuring your standard software is always kept up to date.

Control interface

You can integrate new devices easily and cost effectively into the machine control via the pneumatic and electrical interface.

Laser

TruDisk

Maximum performance from the disk