TruMatic 6000 fiber

Productive thin sheet machine

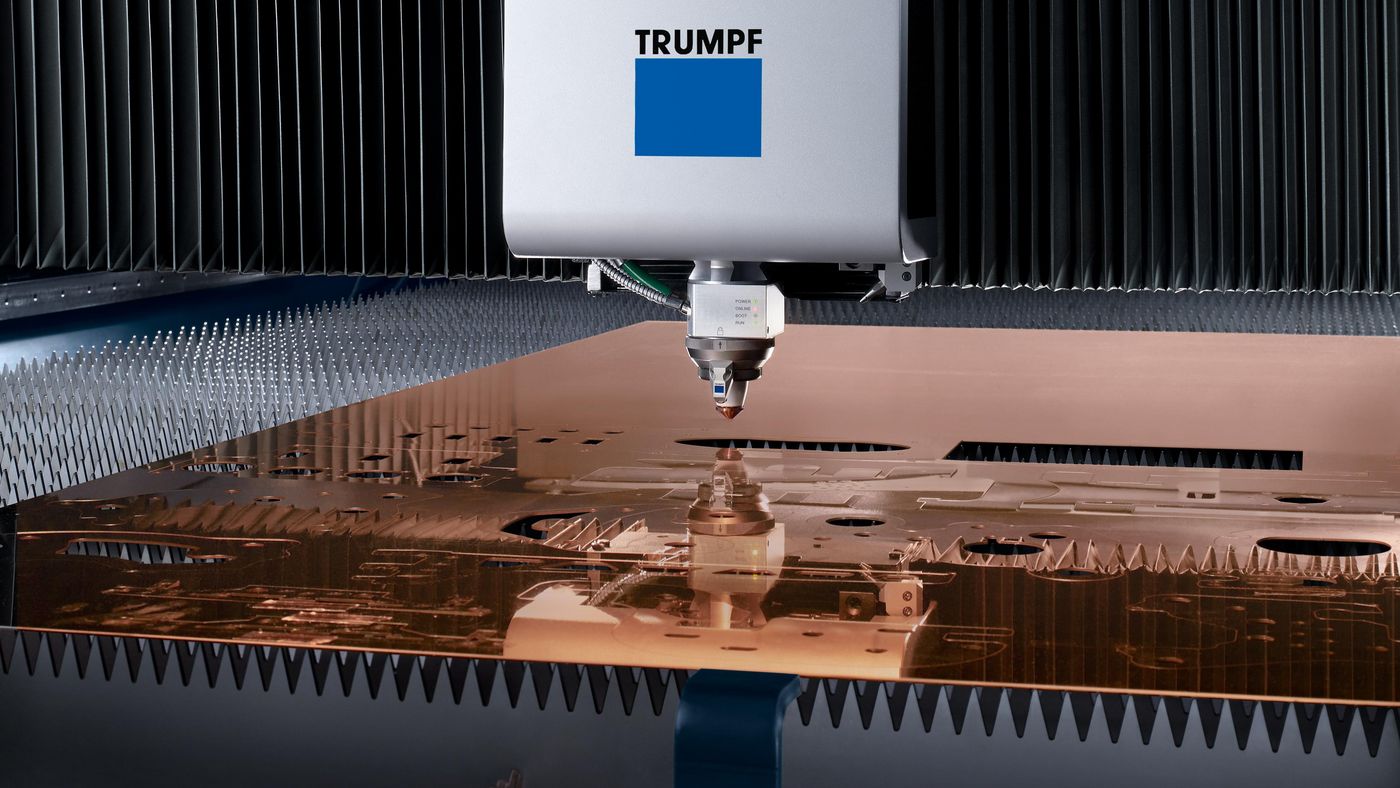

The TruMatic 6000 fiber combines highest process reliability and flexibility. The solid-state laser opens up a wide range of materials to you, and processes thin sheets with cutting speeds of up to 1338 in/min. In this way, you can process non-ferrous metals, film-coated stainless steel, and galvanized sheet particularly productively. Intelligent solutions for operation parallel to production ensure that your investment pays off even faster. Various automation options guarantee process-reliable operation during the night and on the weekend

Equipment

Quality

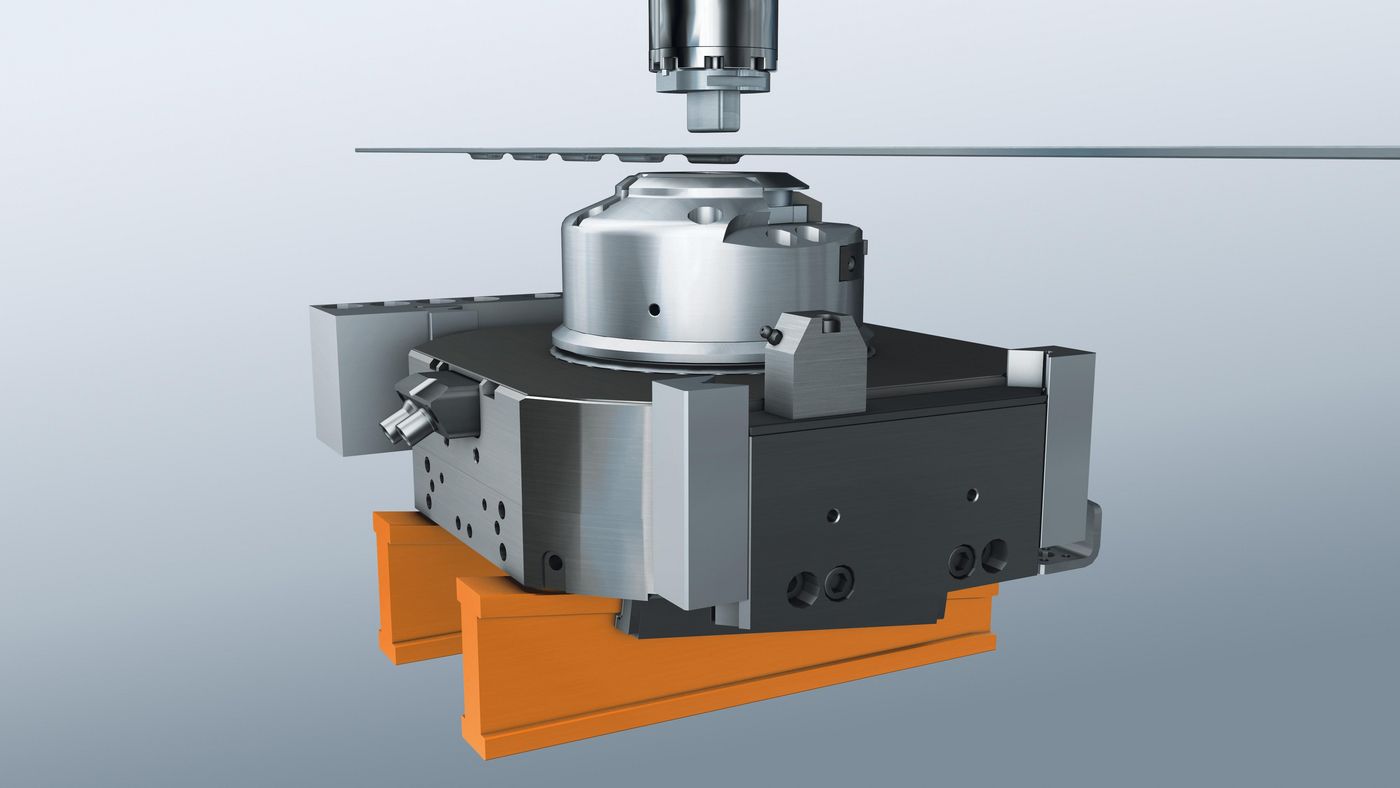

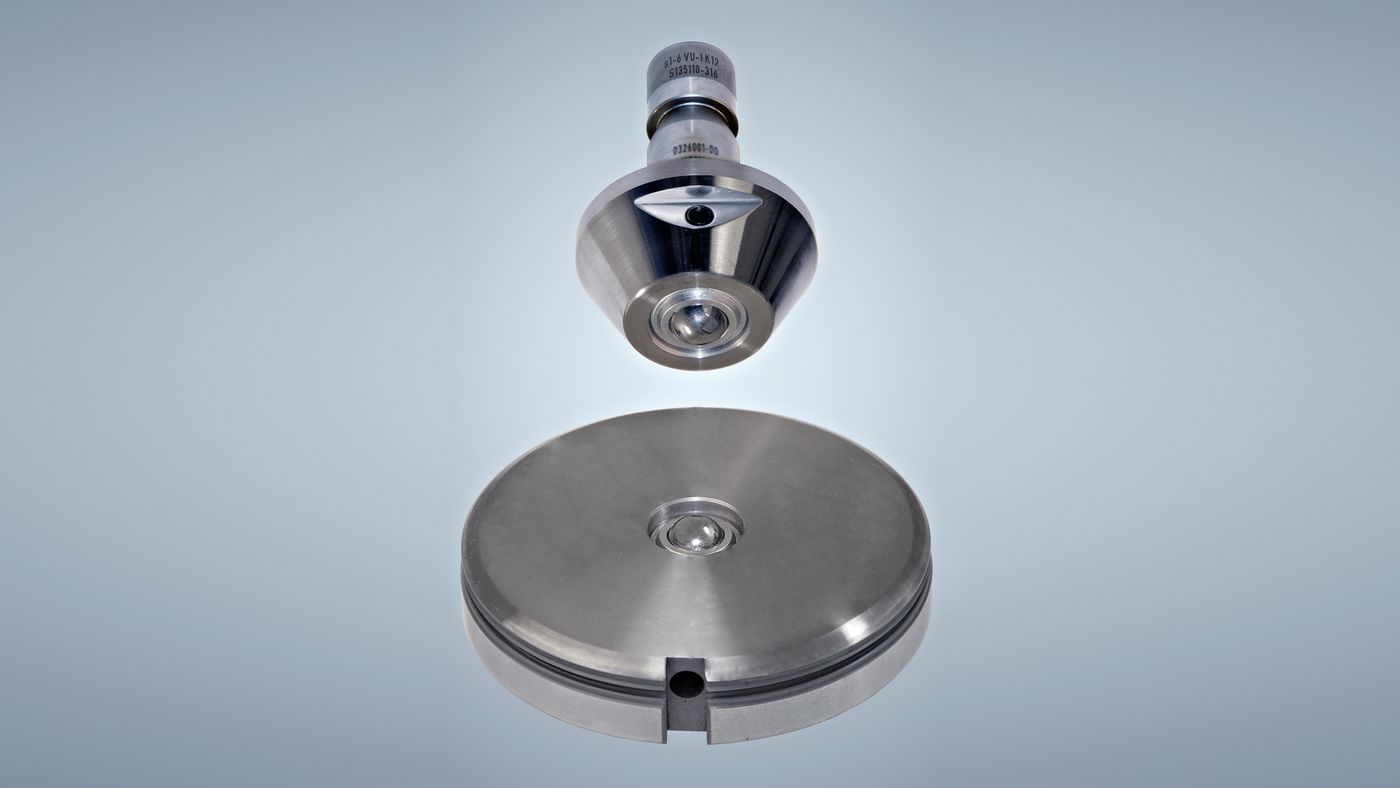

Descending die

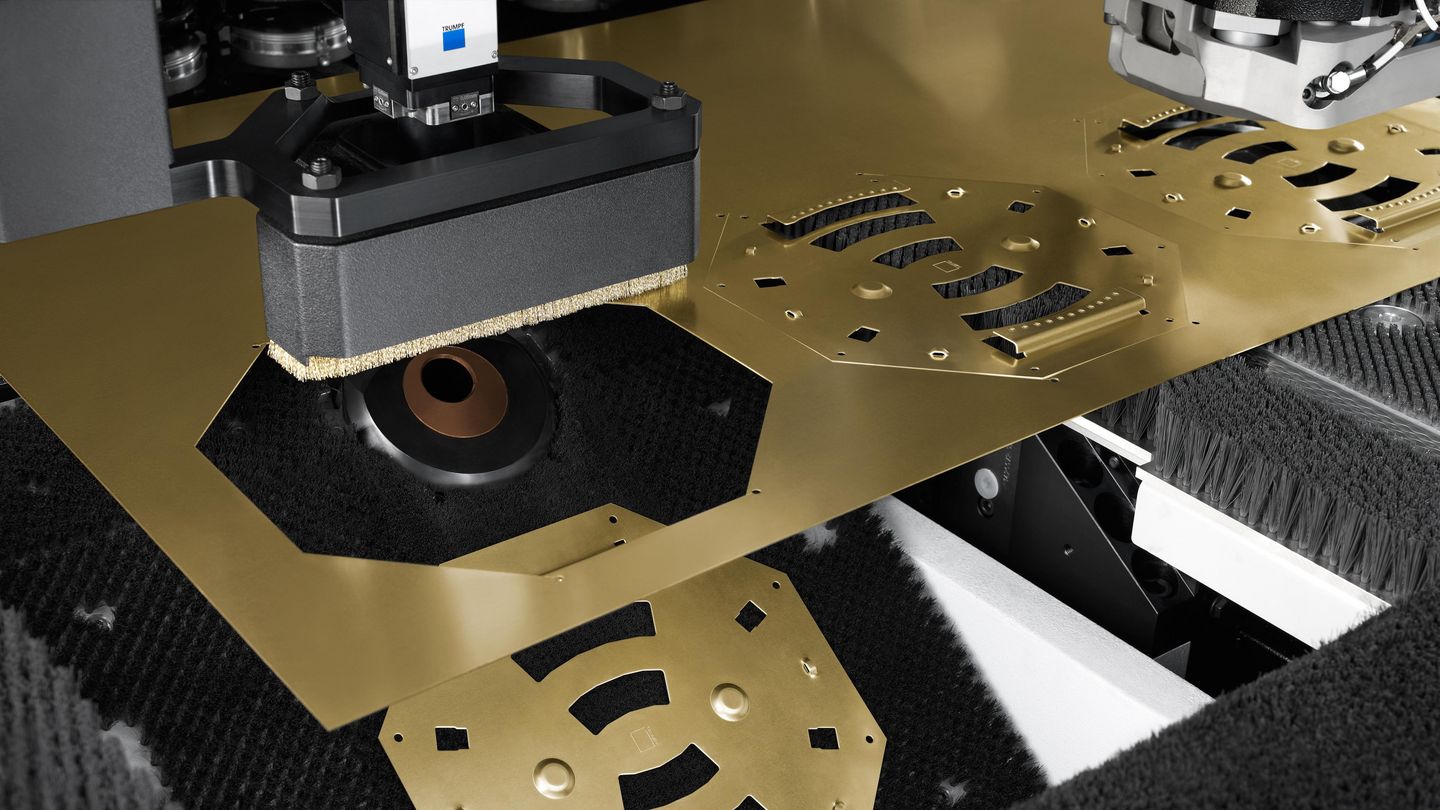

Ball tables or brush tables

Process reliability

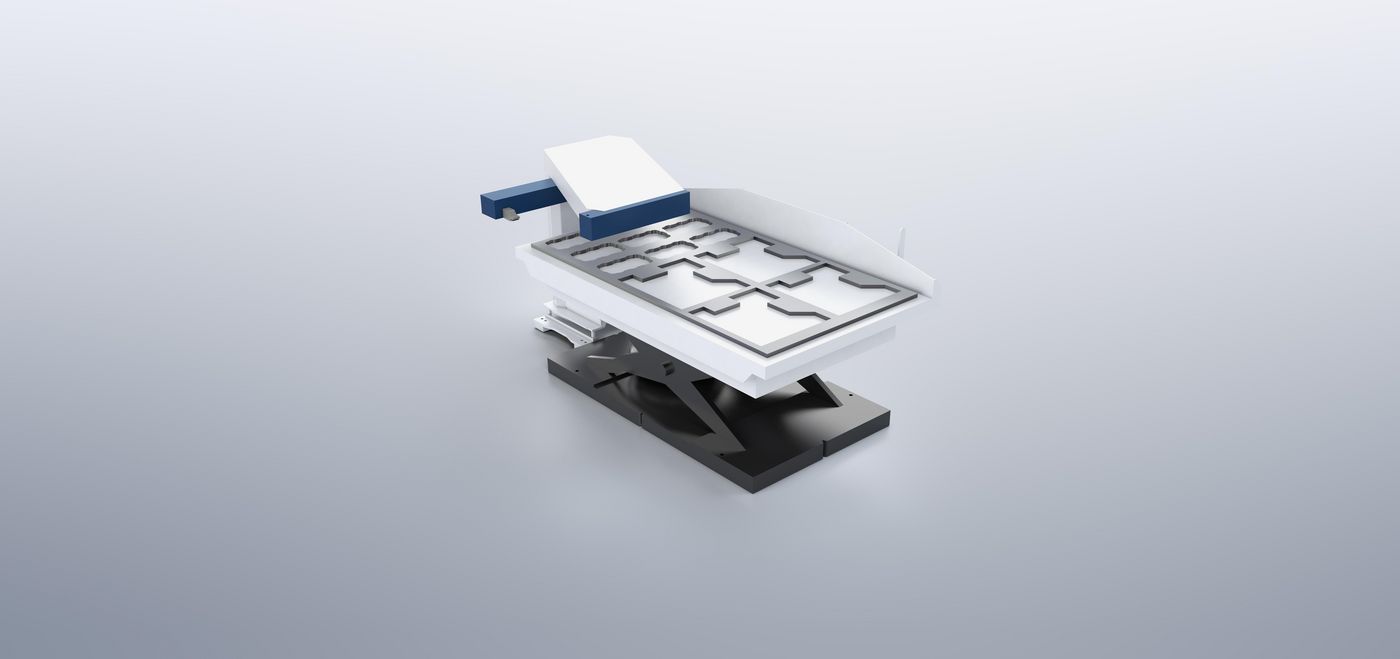

Smart load

Smart unload

Smart punch monitoring

Cost-effectiveness

Integrated flattening

Protective glass

Flexibility

MobileControl app

Oversize format processing

The TruMatic 6000 fiber is available in different sizes. The large version enables the processing of parts in a working area of up to 120 x 42 inches. This means even particularly large parts can be processed and more part geometries are possible.

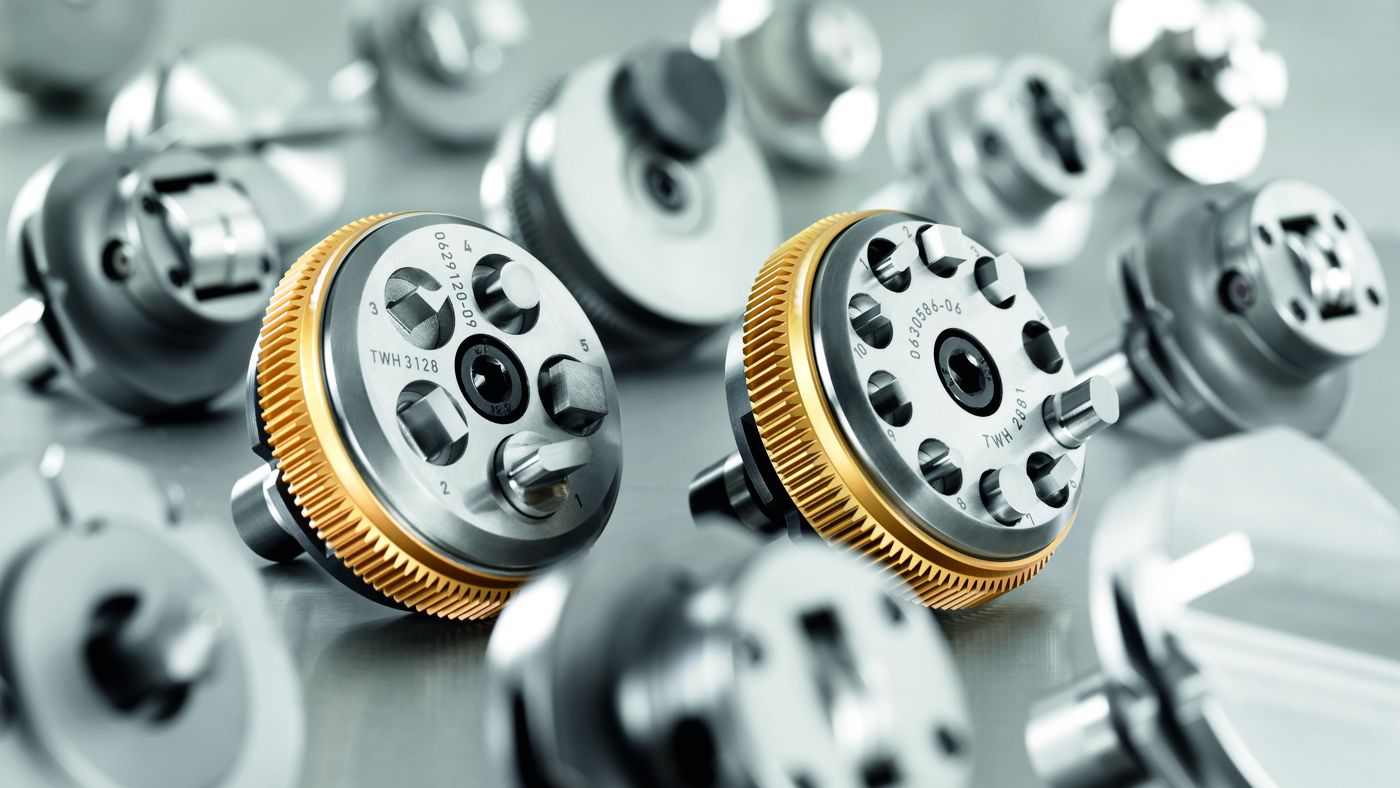

Tools

Roller beading tool

Ball deburring tool

Engraving tool

Punching tools at a glance

TRUMPF offers the world's largest range of punching tools on the market. You will find the perfect solution for every punching and forming Application.

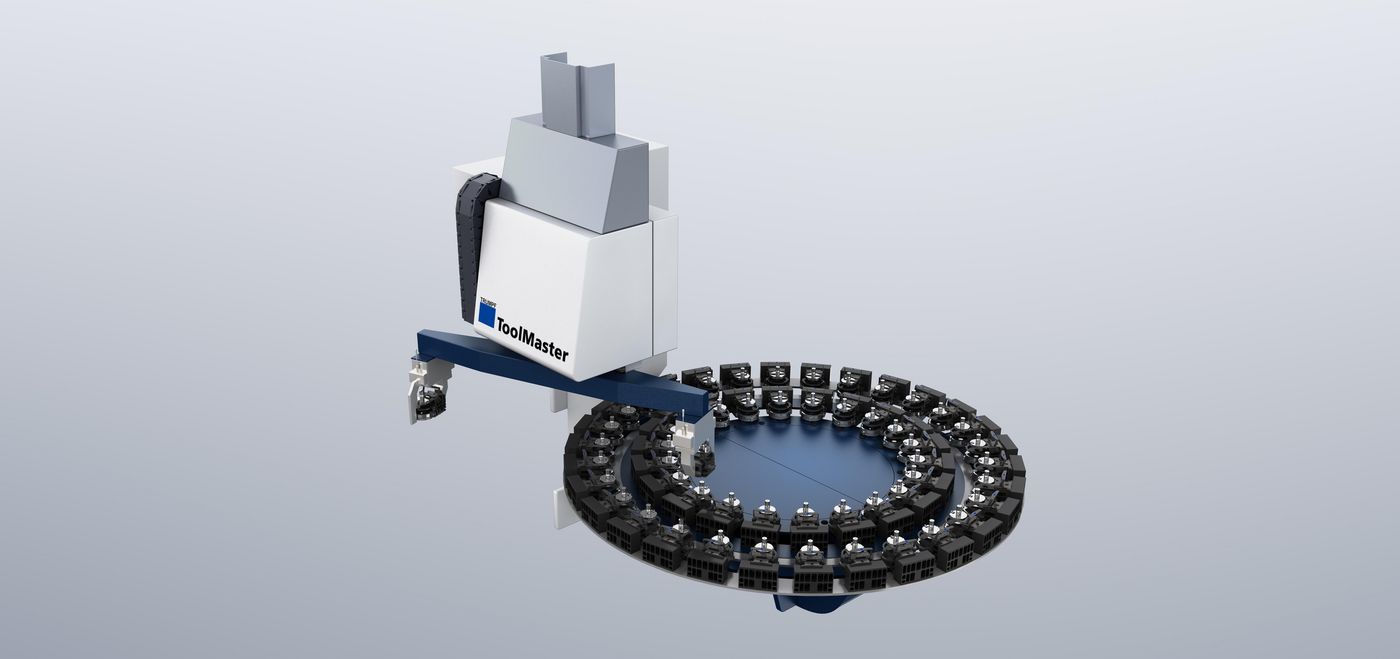

Automation

Loading + unloading + sorting

Sorting

Disposal

Tool handling

Send forespørsel

Feil: Kontaktskjema ble ikke funnet.