TruMatic 7000

Productive high-end machine

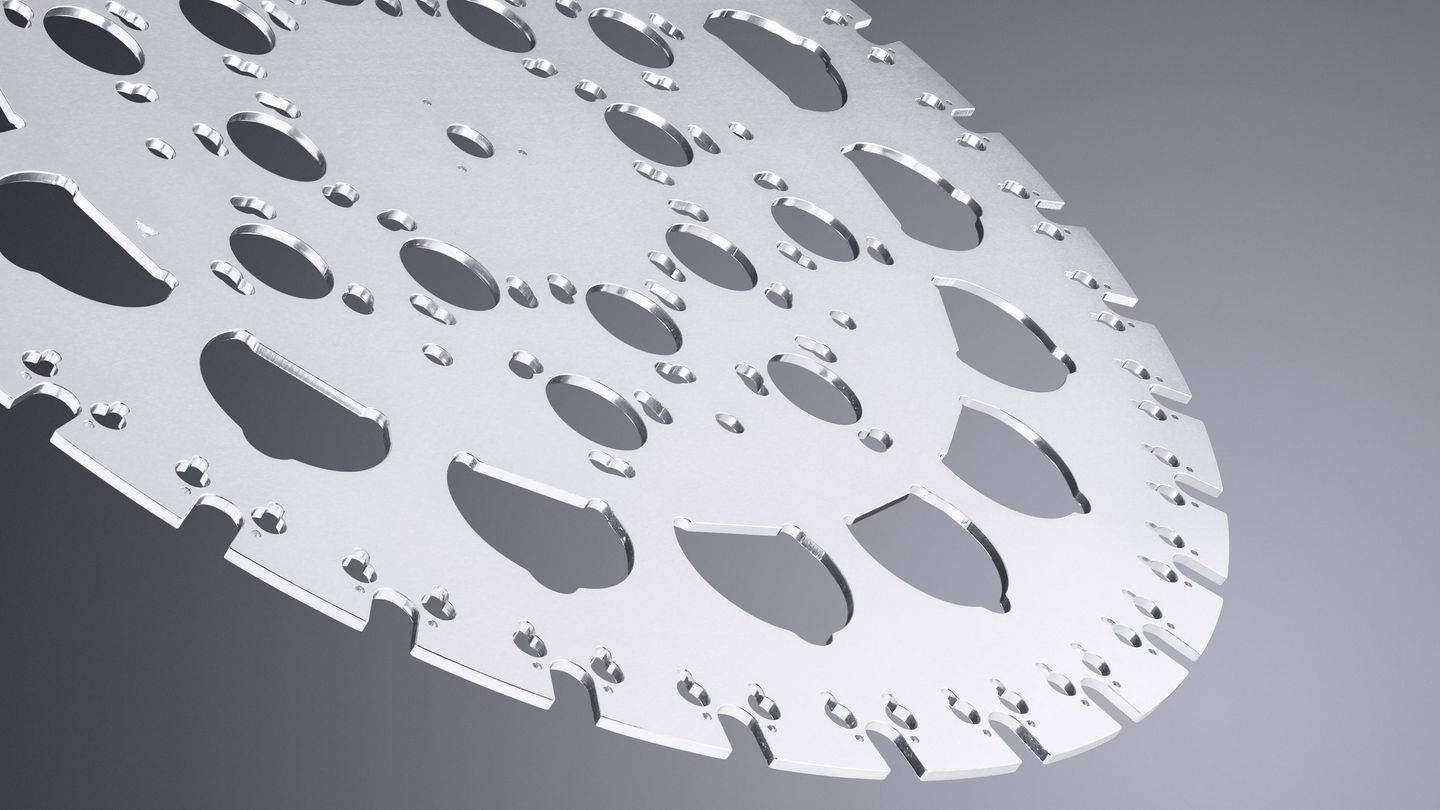

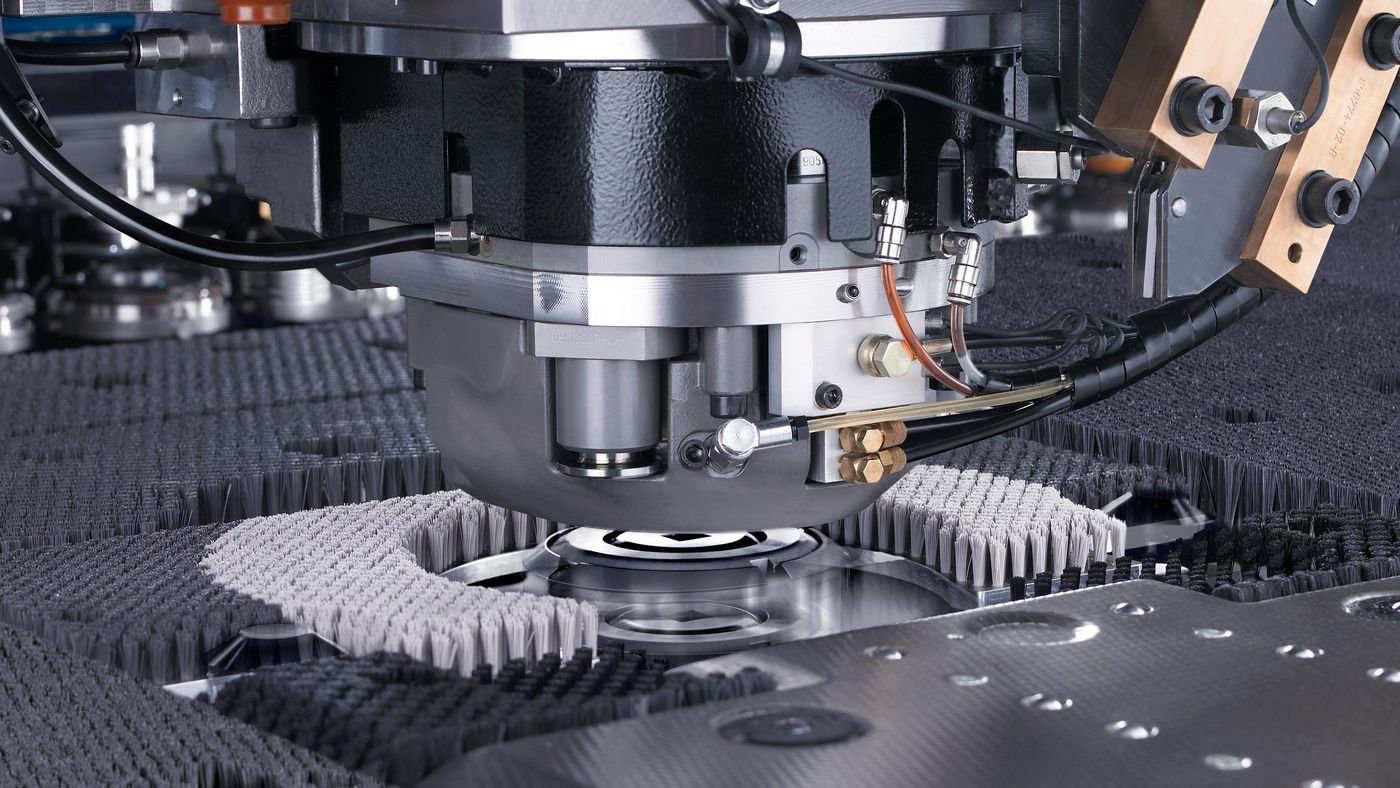

The TruMatic 7000 brings together the advantages of punch and laser processing in a particularly cost-efficient way. The high-end punch laser machine meets high demands in regards to part quality, productivity, and flexibility. With the active die, you can produce scratch-free parts and profit from the greatest level of flexibility when forming.

Equipment

Quality

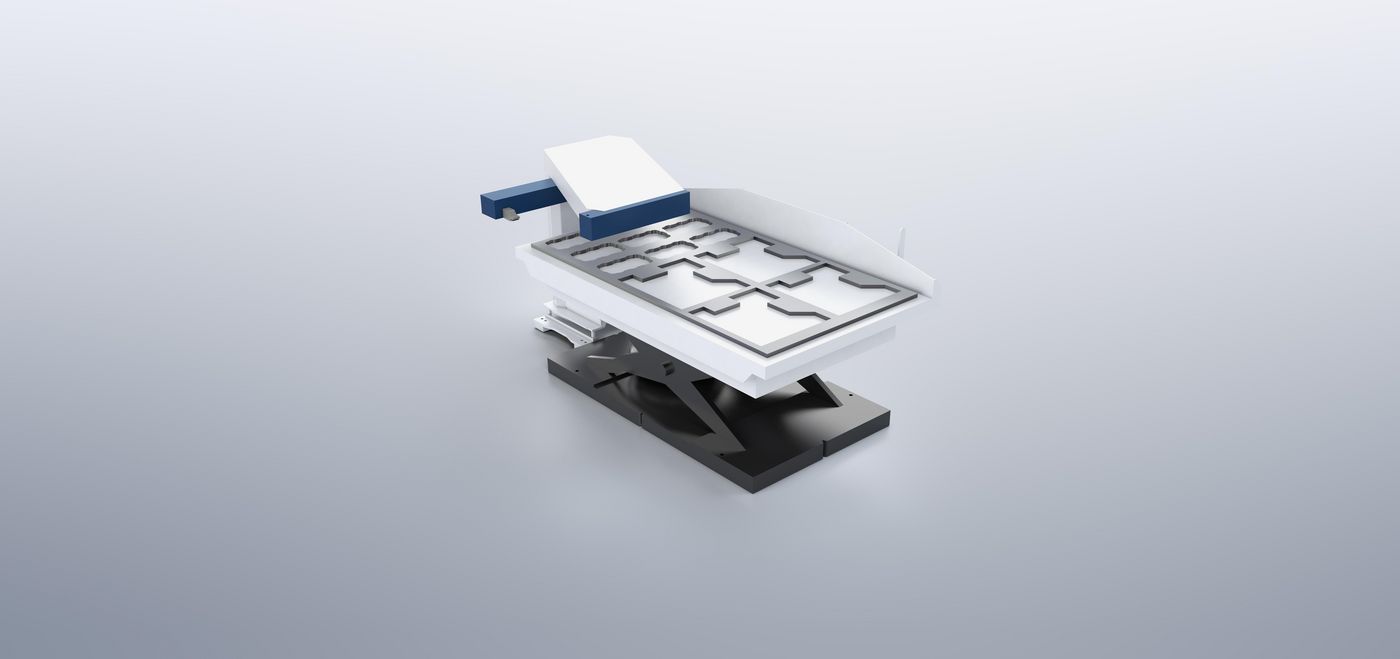

Active die

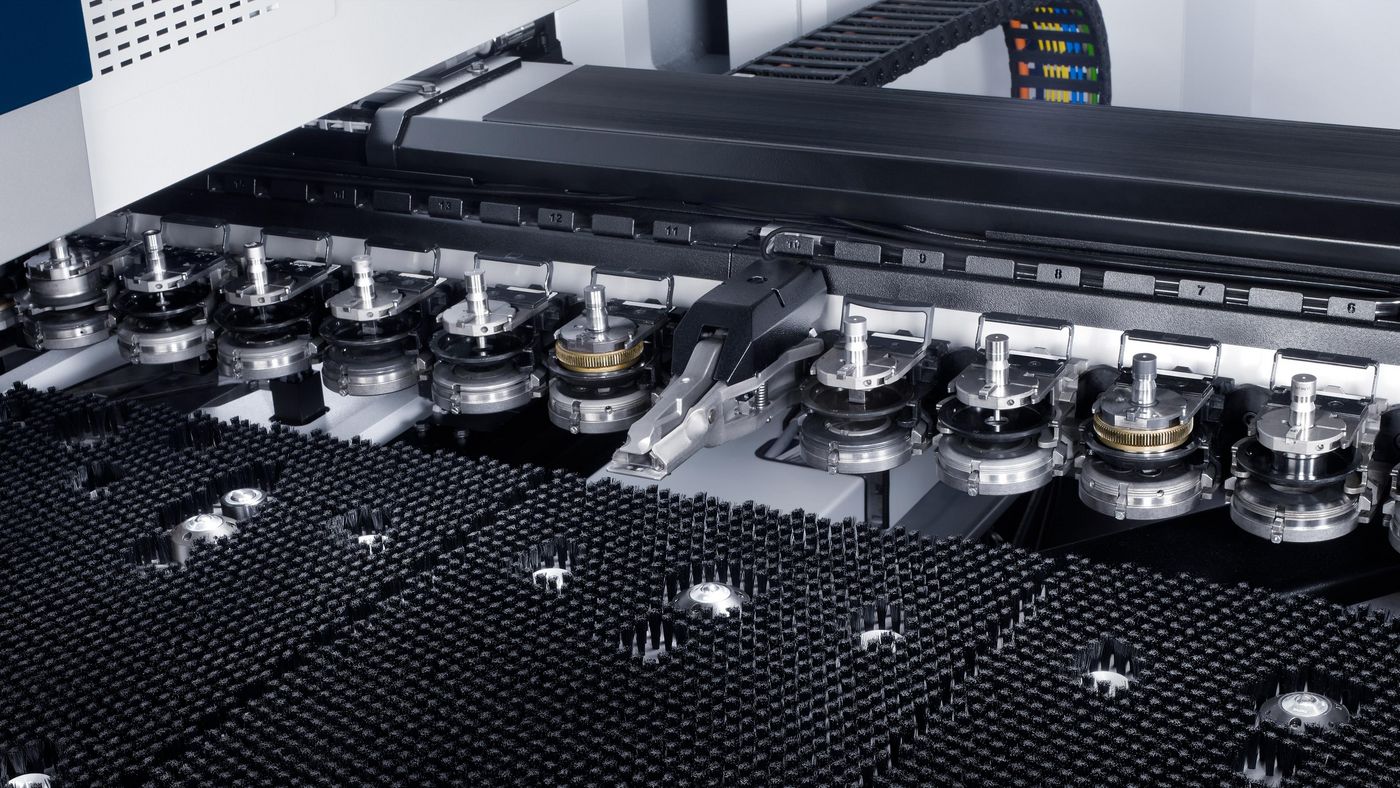

Ball tables or brush tables

Productivity

Nozzle changer

Process reliability

Smart functions: smart load

Smart functions: smart unload

Smart functions: smart punch monitoring

Cost-effectiveness

Integrated flattening

Flexibility

MobileControl app

Oversize format processing

The machine is available in a large and medium format as desired. The large format enables your sheet metal to be processed in a working area of up to 120 x 60 in. This increases the number of potential part geometries, thereby offering you even greater flexibility.

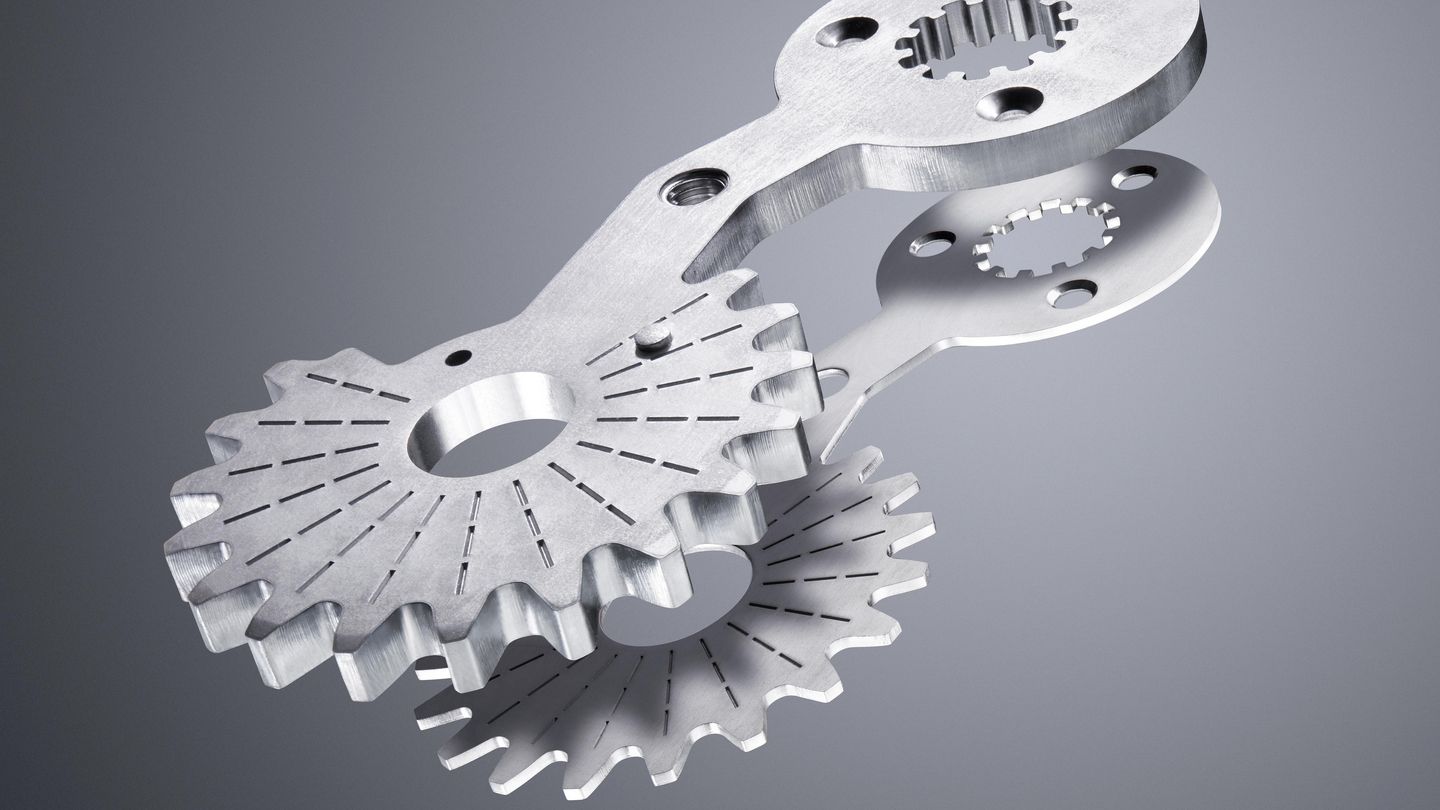

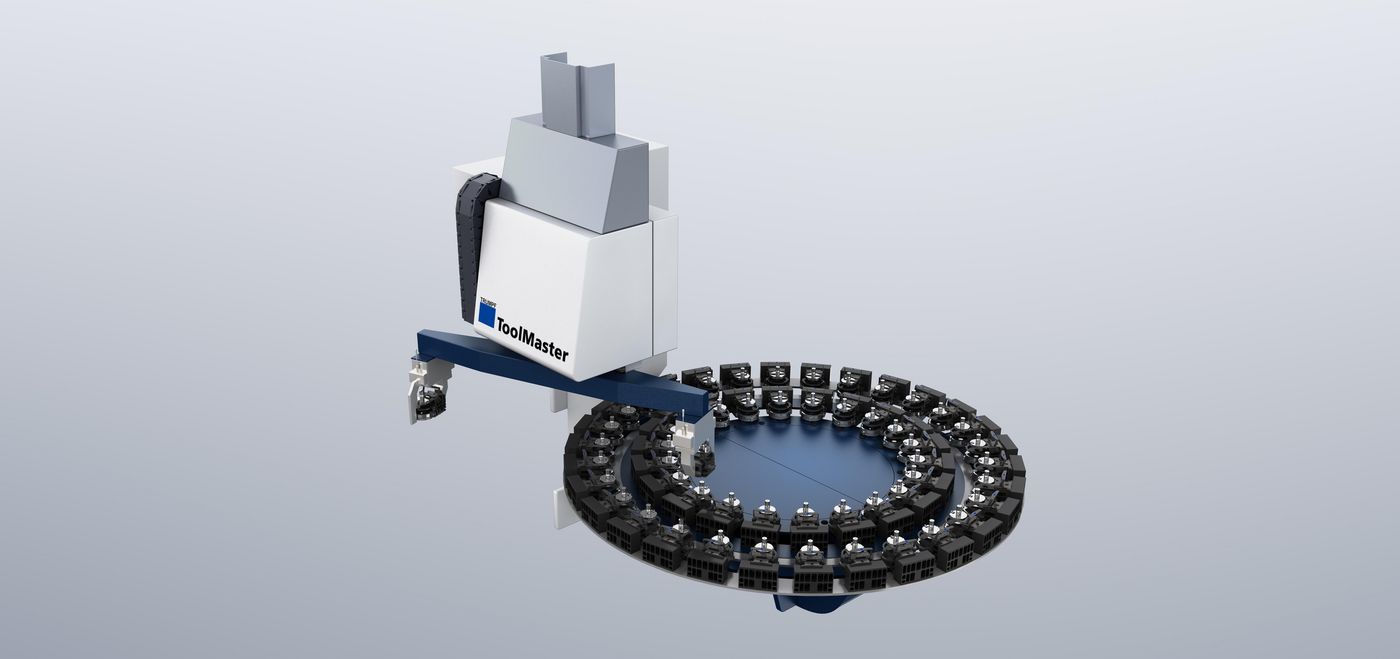

Tools

Cluster tool for integrated flattening

Film slitting tool

Punching tools at a glance

TRUMPF offers the world's largest range of punching tools on the market. You will find the perfect solution for every punching and forming application.

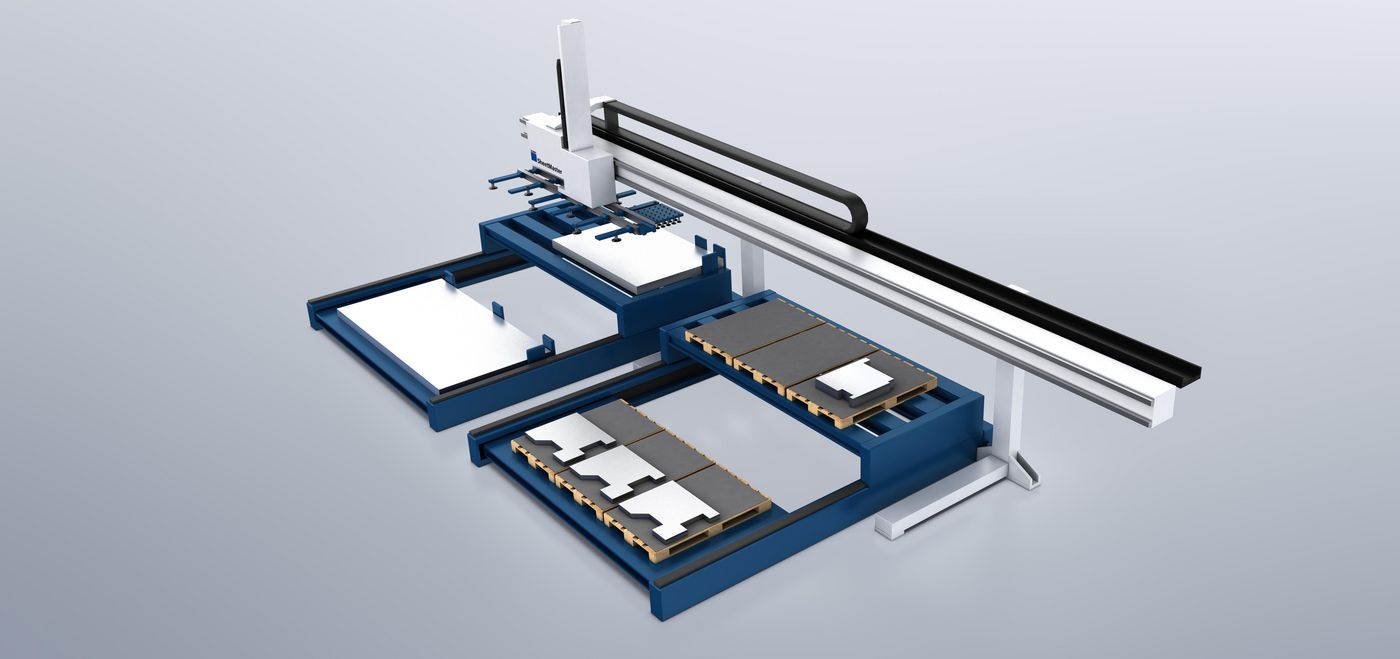

Automation

Loading + unloading + sorting

Loading + unloading

Sorting

Disposal

Tool handling

Send forespørsel

Feil: Kontaktskjema ikke funnet.