Produktbeskrivelse

Diameter of up to 10 in.

Process parts with a diameter of up to 10 in. and wall thicknesses of up to 0.4 in. for mild steel.

Significantly reduced part times

Due to RapidCut, the high feed rates of the solid-state laser come into their own even on smaller contours.

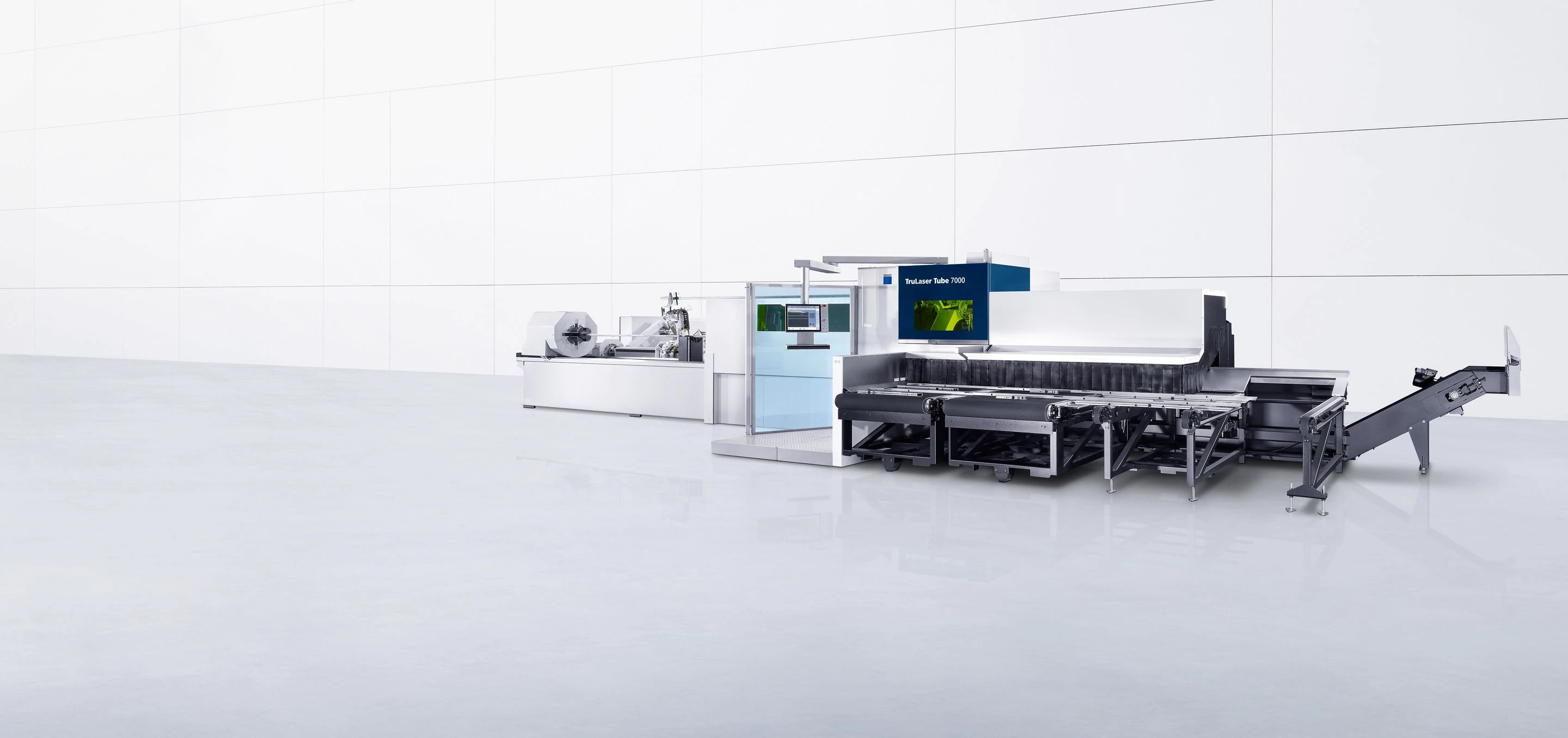

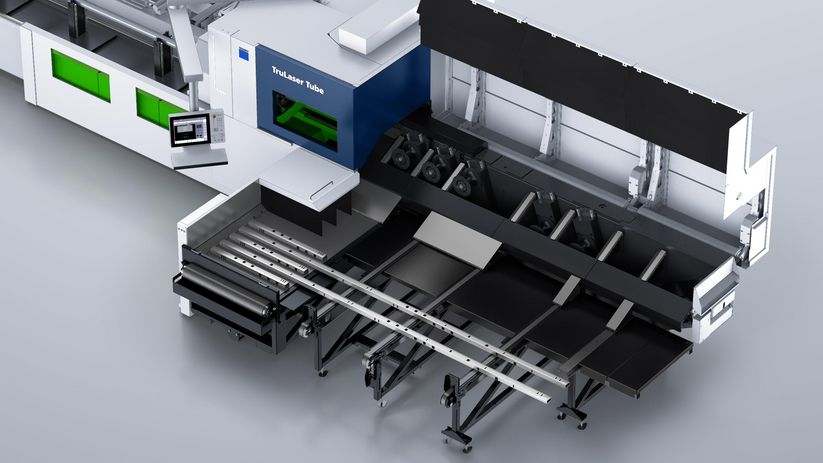

Optimal access to the machine

Thanks to its open concept, the TruLaser Tube 7000 fiber offers optimum access.

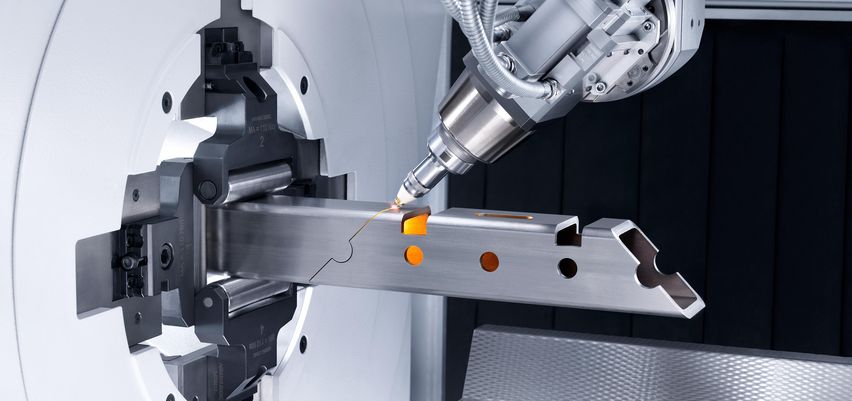

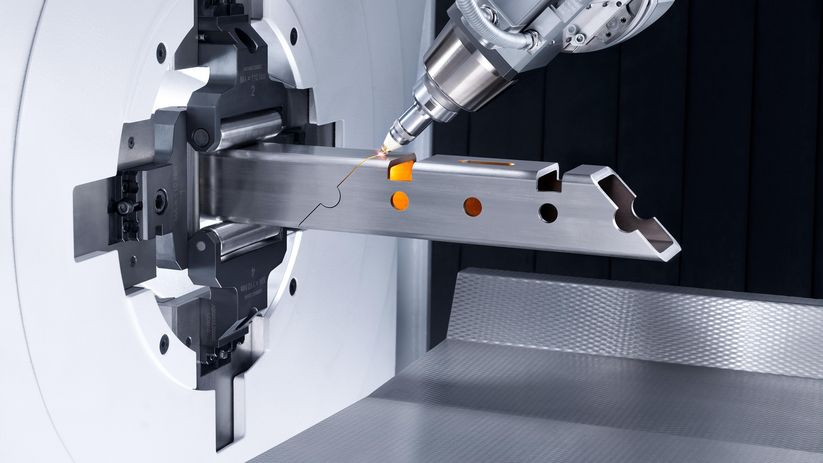

High-quality bevel cuts

The bevel cutting option enables high-quality bevel cuts of up to 45°.

Optimum cutting result

The TruDisk solid-state laser and high-quality cutting data produce the best possible results.

Excellent process reliability

The state-of-the-art sensor system ensures your entire machining process runs smoothly.

Minimal non-productive time

The fully automatic machine settings mean that there is minimal non-productive time when using the TruLaser Tube 7000 fiber.

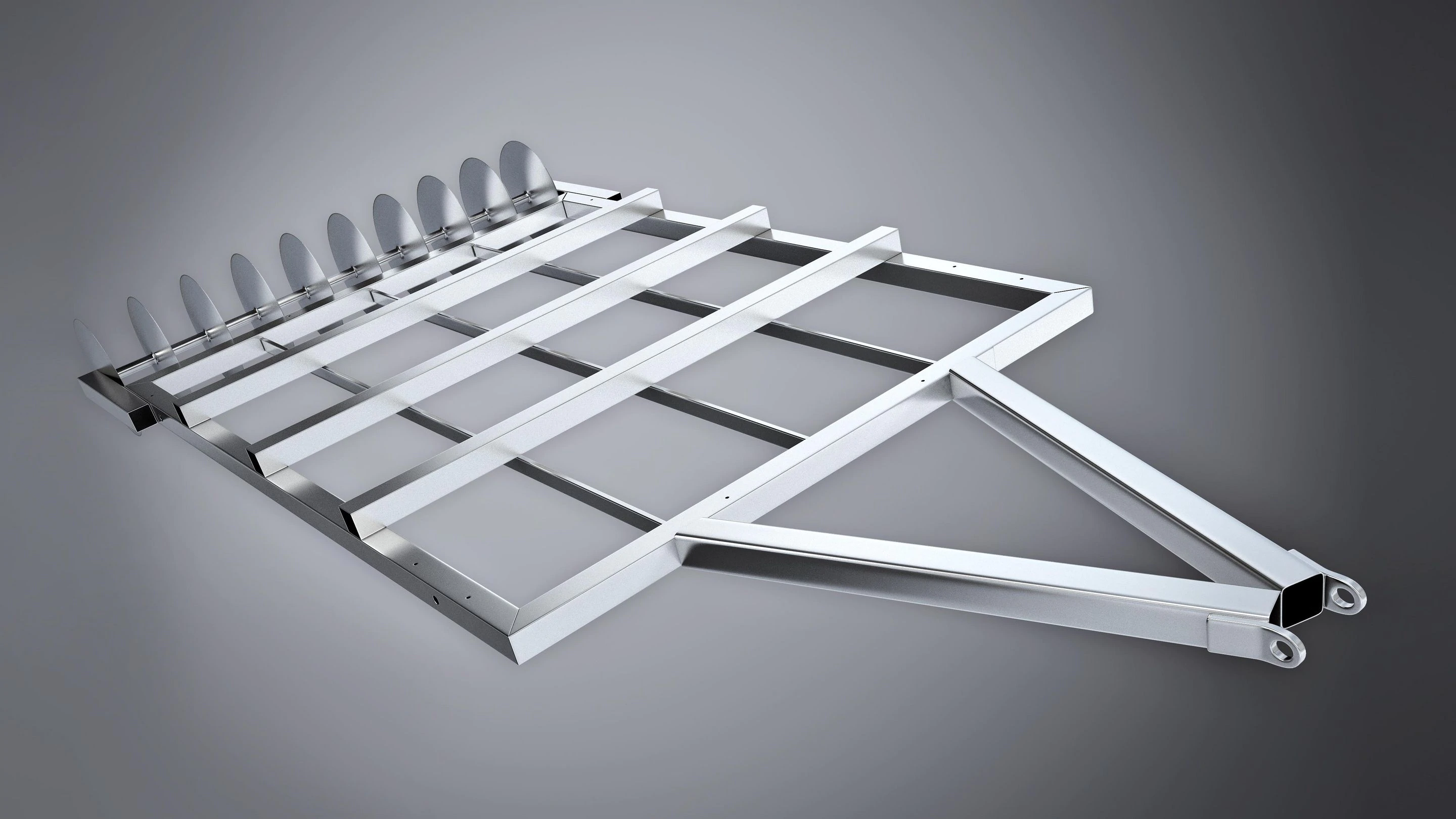

Integration of subsequent processes

The TruLaser Tube 7000 fiber can optionally take over further process steps such as tapping threads.

The highest levels of accessibility and safety in one

The open machine concept and intelligent beam guard provide the perfect combination of optimum safety and the best accessibility for the operator. This means that even individual tubes can be loaded efficiently and parts removed at an ergonomic working height.

Bevel cut

The TruLaser Tube 7000 fiber processes bevel cuts of up to 45 degrees.

RapidCut

With RapidCut, the high feed rates of the solid-state laser come into their own even on smaller contours. This is a significant productivity advantage, particularly in thinner materials.

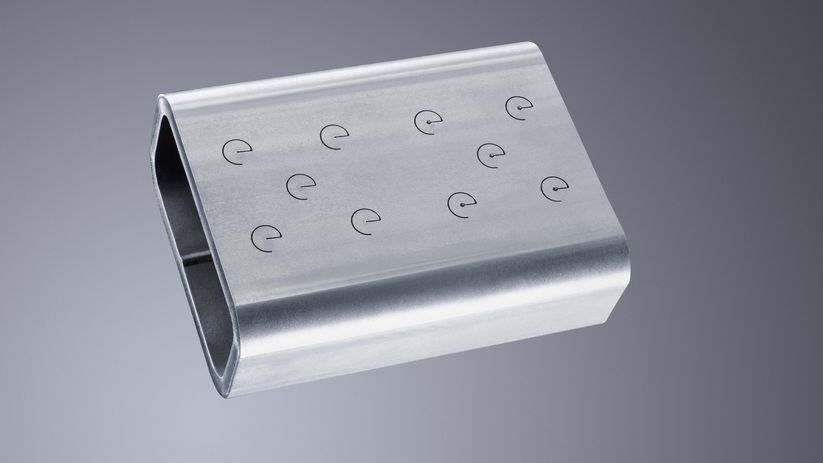

Technology package for tapping

With the new technology package for tapping, additional machining processes such as flow drilling, tapping, and twist drilling are integrated into the machine. Automation means you can benefit from reduced parts handling and a smaller chance of errors.

Swivel-mounted conveyor system

The swivel-mounted conveyor system can be used for small lot sizes and special profiles.

Automatic stepped rollers

The step rollers support the tubes while also moving them sideways, and adjust automatically to various diameters.

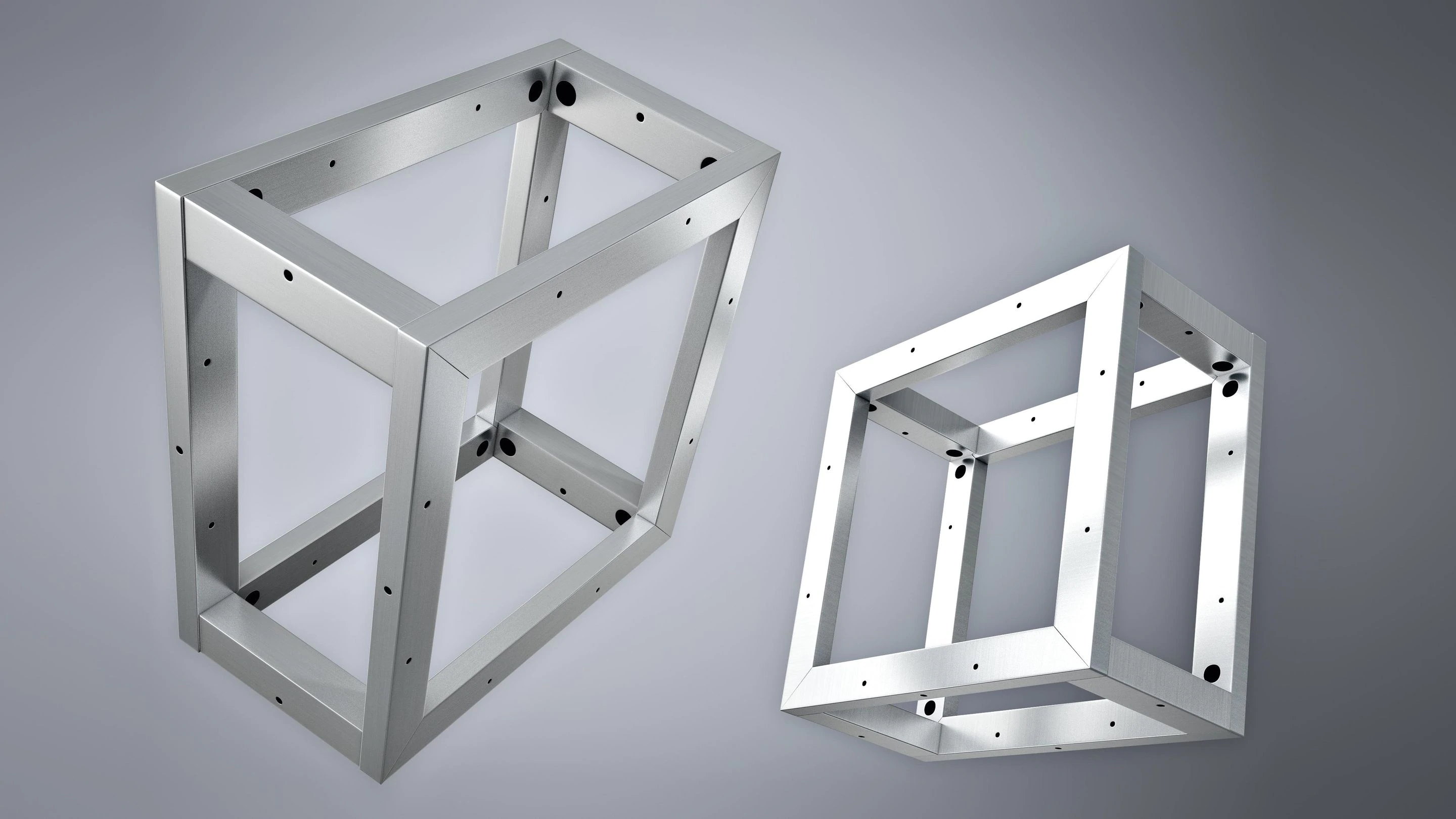

Self-centering collet chuck

The collet chucks position and hold your tubes in place without damaging the materials. The self-centering clamping system with continuous sensor monitoring adapts to every tube geometry. This means you benefit from high part precision.

Equipment

Smart profile detection

With smart profile detection, you can load even profiles with challenging geometries automatically.

SeamLine Tube

SeamLine Tube identifies weld seams or markings in order to align each tube correctly on the machine. As an option, the function can also scan the inside of the tube.

RapidCut

With RapidCut, the high feed rates of the solid-state laser come into their own even on smaller contours. This is a significant productivity advantage, particularly in thinner materials.

Bevel cuts of up to 45 degrees

You can expand your range of parts with high-quality bevel cuts of up to 45°.

Single-cutting-head strategy

With the one-cutting-head strategy, you can process multiple material types and thicknesses with the laser without changing the cutting head.

Sensor system

Your machine is ahead of the game: sensors detect whether or not a part has been correctly ejected.

Condition Guide

One glance is enough: Due to the new Condition Guide function, you are always informed about the condition of your machine. A traffic light system shows the status of important elements which influence the cutting capability of the machine. Condition Guide will give you recommendations for action as required. Process diagrams facilitate forecasting as to when action may need to be taken. Maintenance work can therefore be planned efficiently.

MobileControl app

With the MobileControl app, you can operate and monitor your machines easily and with flexibility as the app transmits the interface of the standard control panel onto the touch screen of your tablet PC. The app enables you to call up different machine information at different places in the working environment of the machine, such as the tube storage, or to change the program.

Magnetic coupling

The magnetic coupling with bellows protects the cutting head against potential damage and dirt, especially in the event of a cutting head collision. This means that production can be resumed after a short time.

Dot Matrix Code

Label your parts quickly and reliably with a standardized industry code – the Dot Matrix Code feature enables this.

Conveyor tables

Conveyor tables at an ergonomic height make it easier to unload tubes and profiles. They also serve as a practical material buffer.

FocusLine

No more adjustments by hand: the FocusLine control mechanism keeps the focal position of the laser constant and automatically adapts it to the material.

PierceLine

PierceLine controls and monitors the piercing process. The piercing process is ended as soon as the material is completely cut through. This leads to more accurate results and shorter processing times.

Automation

Loading

The LoadMaster Tube loading unit means you can set up much faster because the bundle space automatically provides the unprocessed material. The swivel-mounted conveyor system shows its strengths, especially with small lot sizes, intermediate production, and special profiles. It is also possible to set up the LoadMaster at the front of the machine. This enables you to adapt the layout of the machine to your material flow.