SBM-XL G2S2

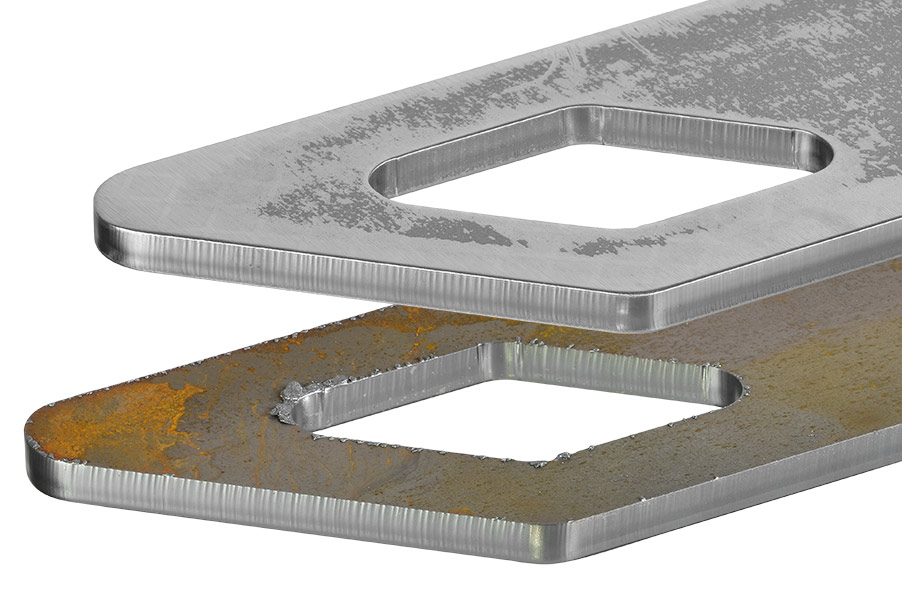

Deburring and edge rounding of parts up to 120 mm material thickness

Processing both sides of the parts simultaneously eliminates the need of turning heavy parts and processing them for a second time

Simultaneous deburring and edge rounding on interior and exterior contours

Dry operation

Simple, intuitive operation

The processing units can be individually adjusted or turned on and off electrically.

Maximum productivity while maintaining machining quality

The cross-machining principle guarantees optimum tool utilisation over the entire working width.

Faster and simpler tool change within just a few minutes

Modular and compact in modern machine design – smaller footprint

Improved work environment – Reduction of dust, dirt and noise

Optionally available: Conveyor Technology; Handling Systems, Automation; Custom Solutions

For repeated customer requirements, processing parameters can be called up quickly and easily through predefined programs.

Up to 60 % work time savings compared to one-side processing grinding machines

Du kan også finne mer informasjon på LISSMAC sine nettsider