TruMatic 1000 fiber

Efficient compact machine

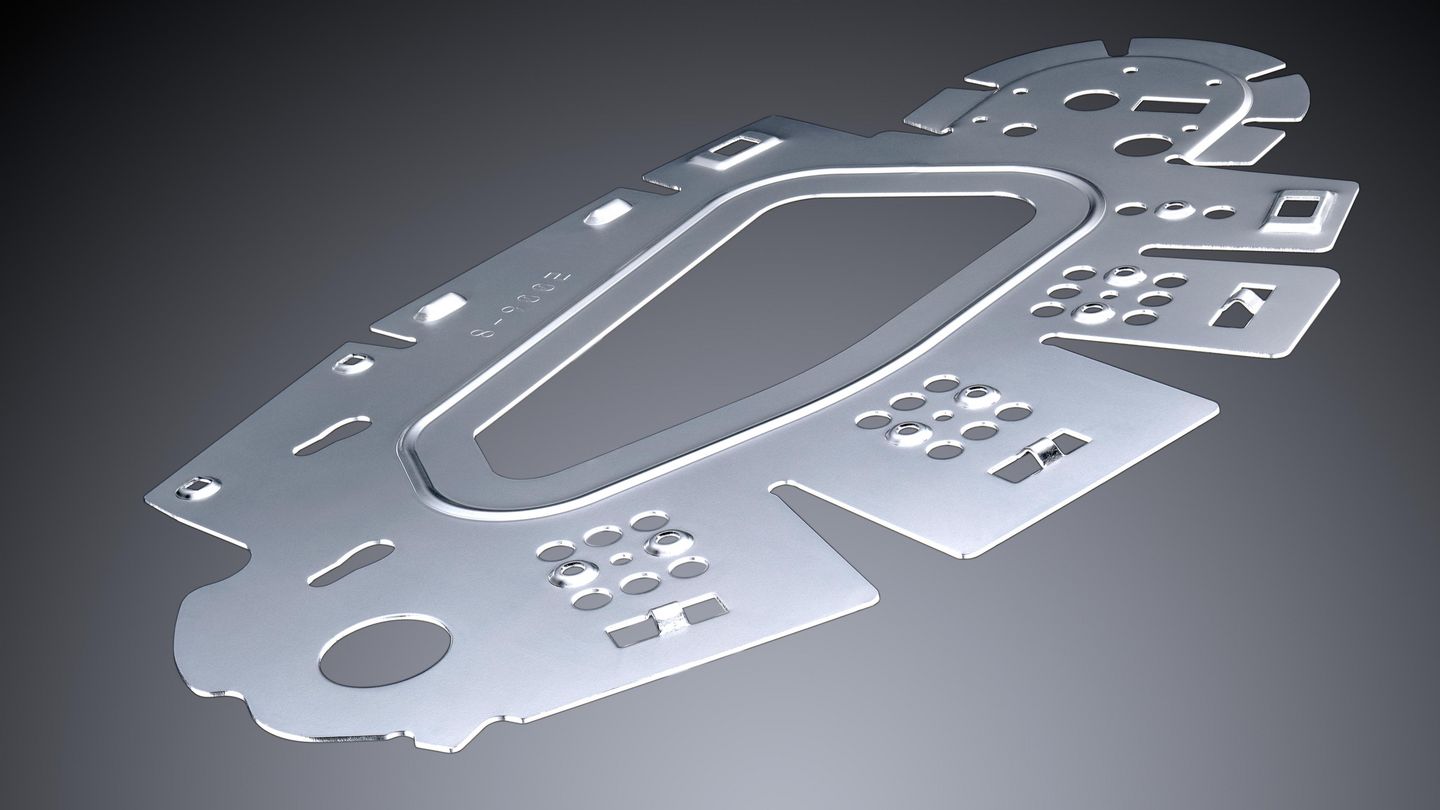

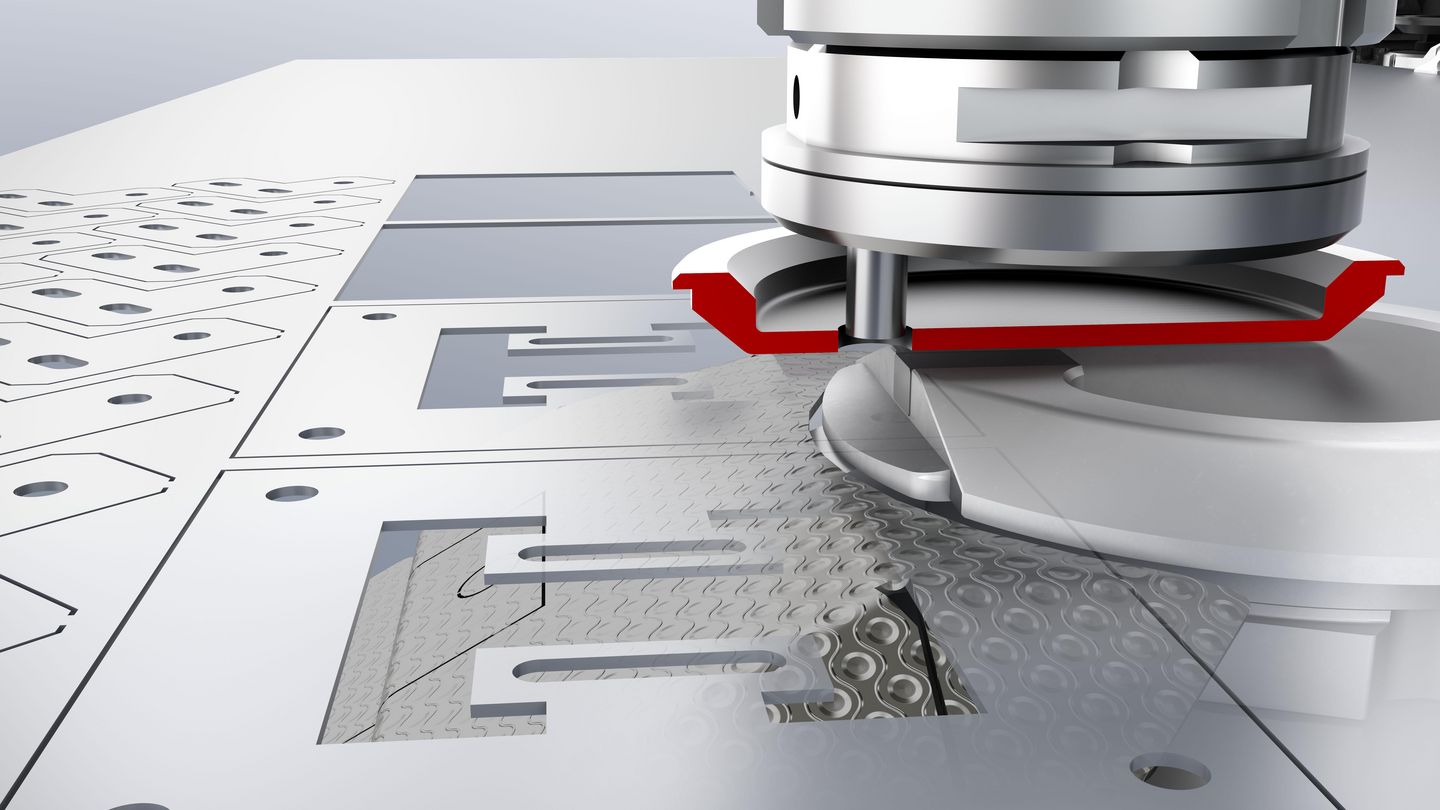

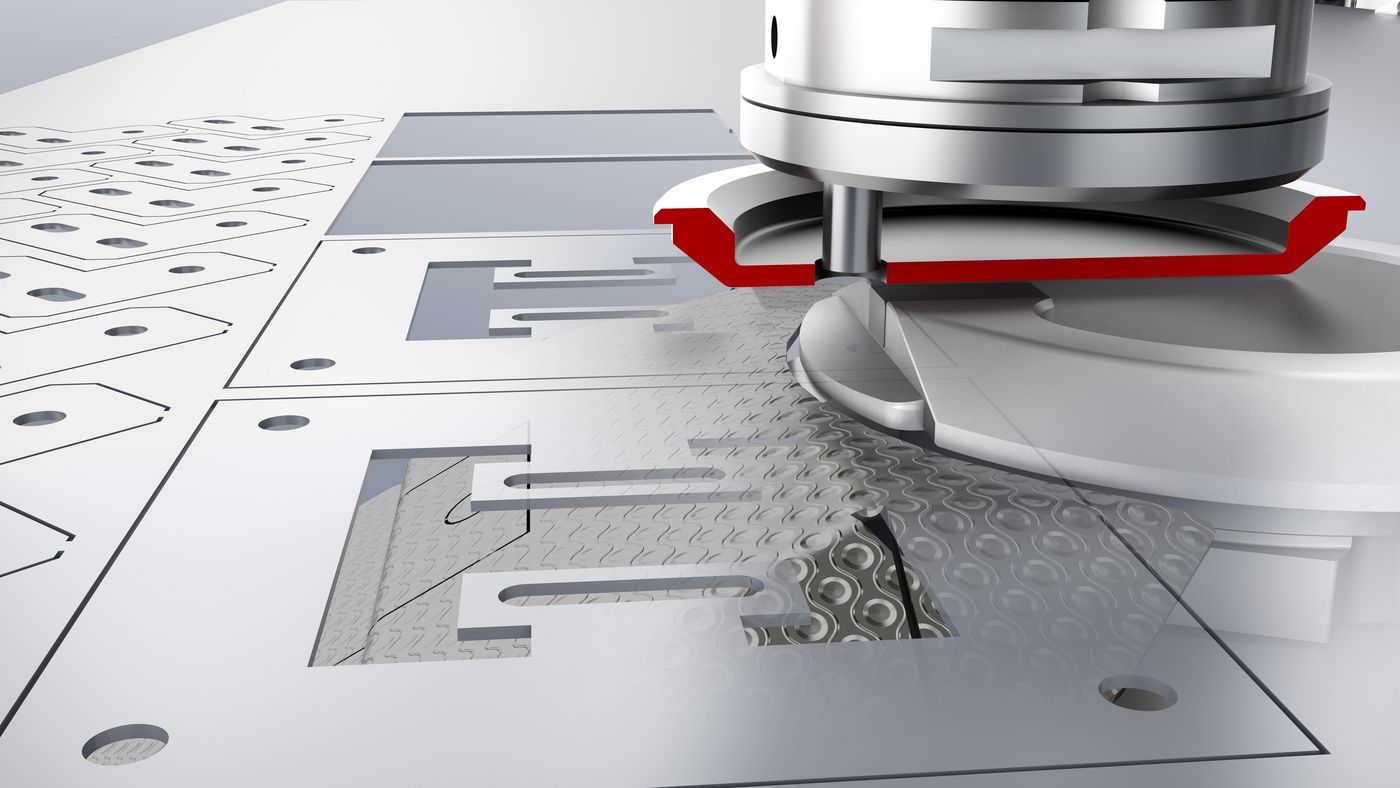

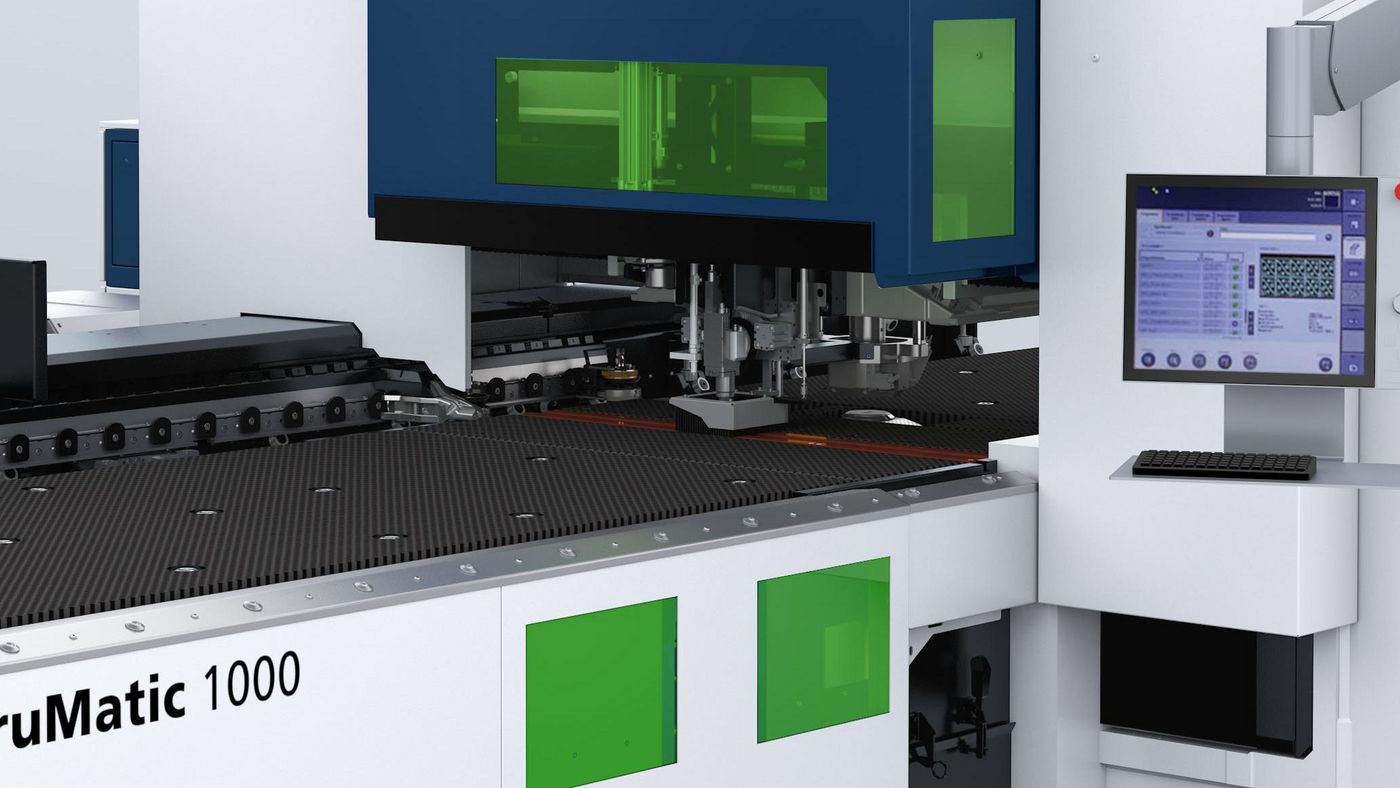

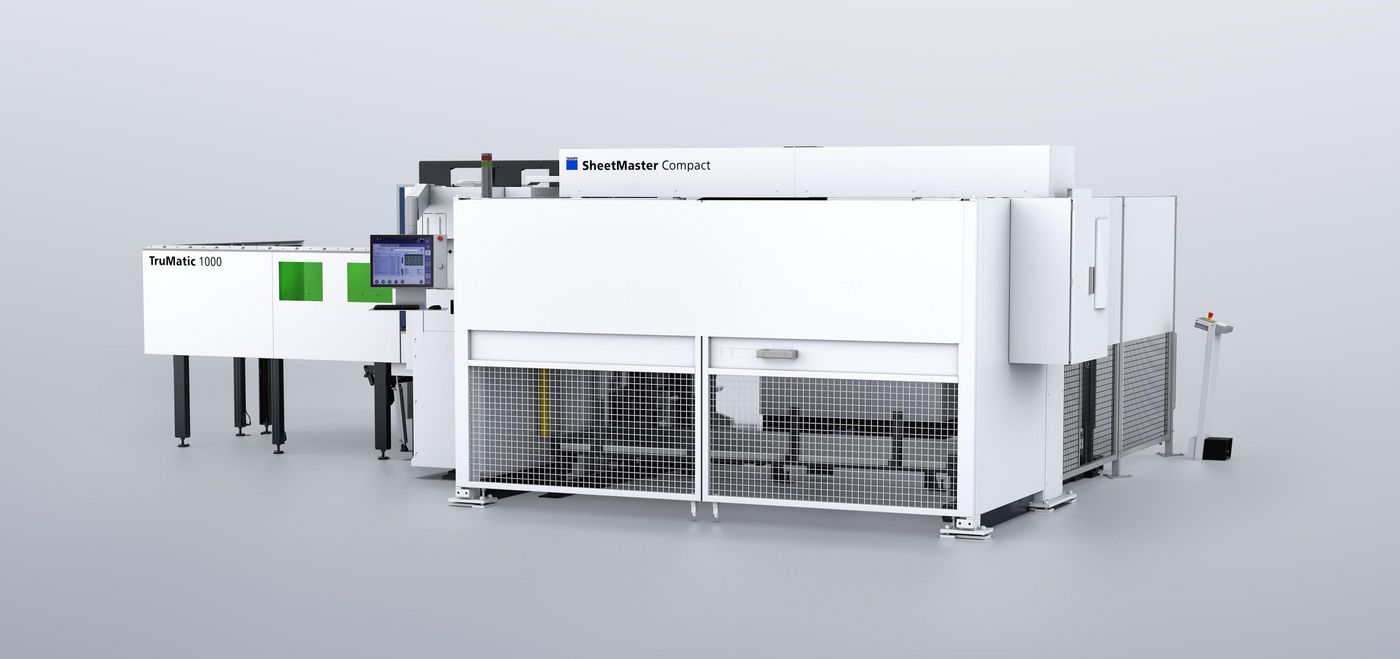

The TruMatic 1000 fiber is a laser machine that punches holes, bends flanges, and forms threads. It is the world’s most compact punch laser machine. The TruMatic 1000 fiber is available as a complete solution, but can also be upgraded to a punch laser machine gradually, starting from the TruPunch 1000 entry-level punching machine. Discover the clever solutions for part sorting and automated operation.

Equipment

Numerous innovative solutions and functions make the TruMatic 1000 fiber the perfect entry-level model for punch laser Processing.

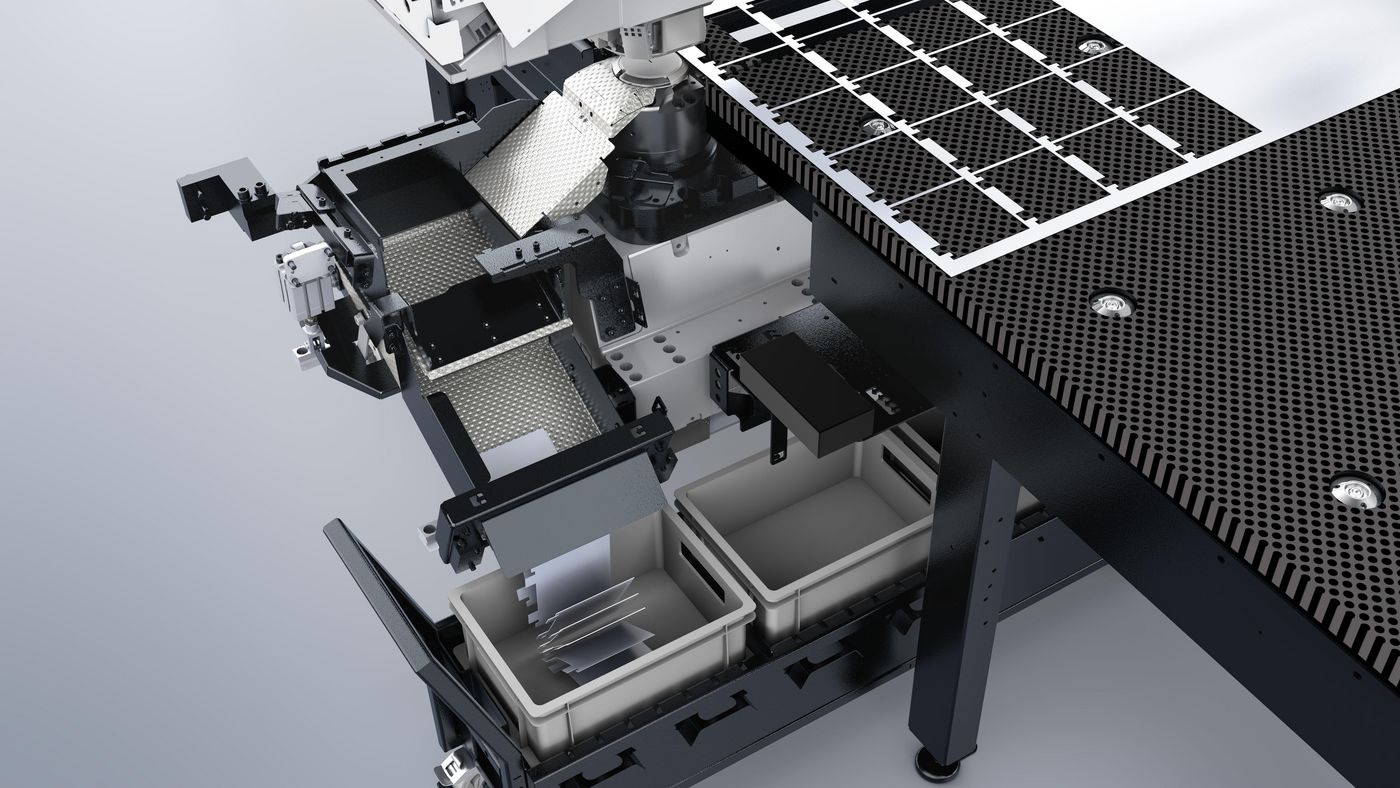

Ejection of small parts

Sorting function

Brush table/ball table

Smart punch monitoring

Parts conveyor belts

Chip conveyor

Preparation for laser network

The laser can be equipped with an additional output for if you wish to operate the machine in a laser network. In a laser network, a TruDisk supplies several TRUMPF machines.

Tools

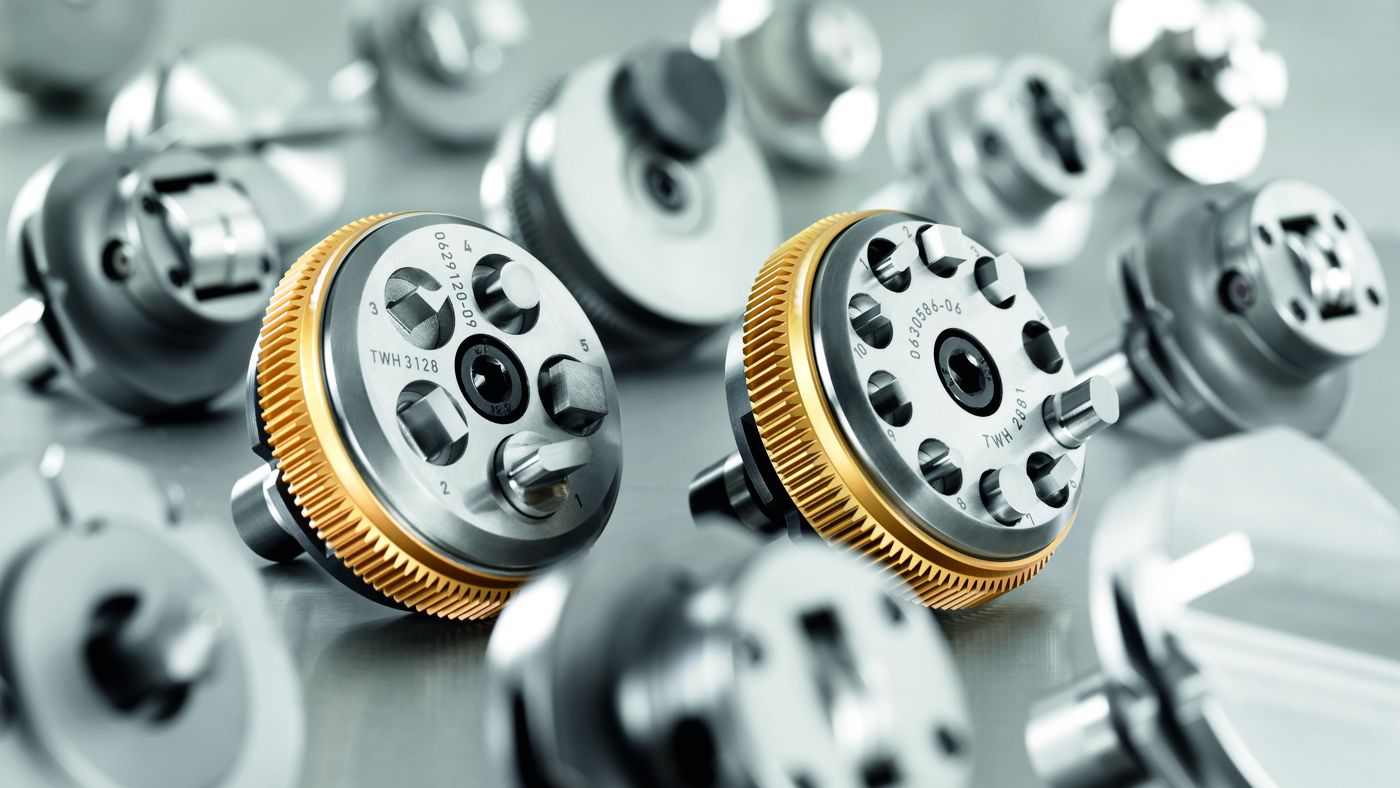

MultiTool

MultiBend

Ejector tool for sorting

Punching tools at a glance

TRUMPF offers the world's largest range of punching tools on the market. You will find the perfect solution for every punching and forming application.

Automation

Loading + unloading

The SheetMaster Compact takes over the process-reliable loading of sheets as well as the unloading of microjoint sheets and scrap skeletons. In this way, the machine operates completely automatically, if required, with a load capacity of up to three tonnes. This increases productivity and also relieves the strain on the operator.

Send forespørsel

[contact-form-7 id="11912" title="Forespørsel"]