TruMatic 6000

The robust universal machine

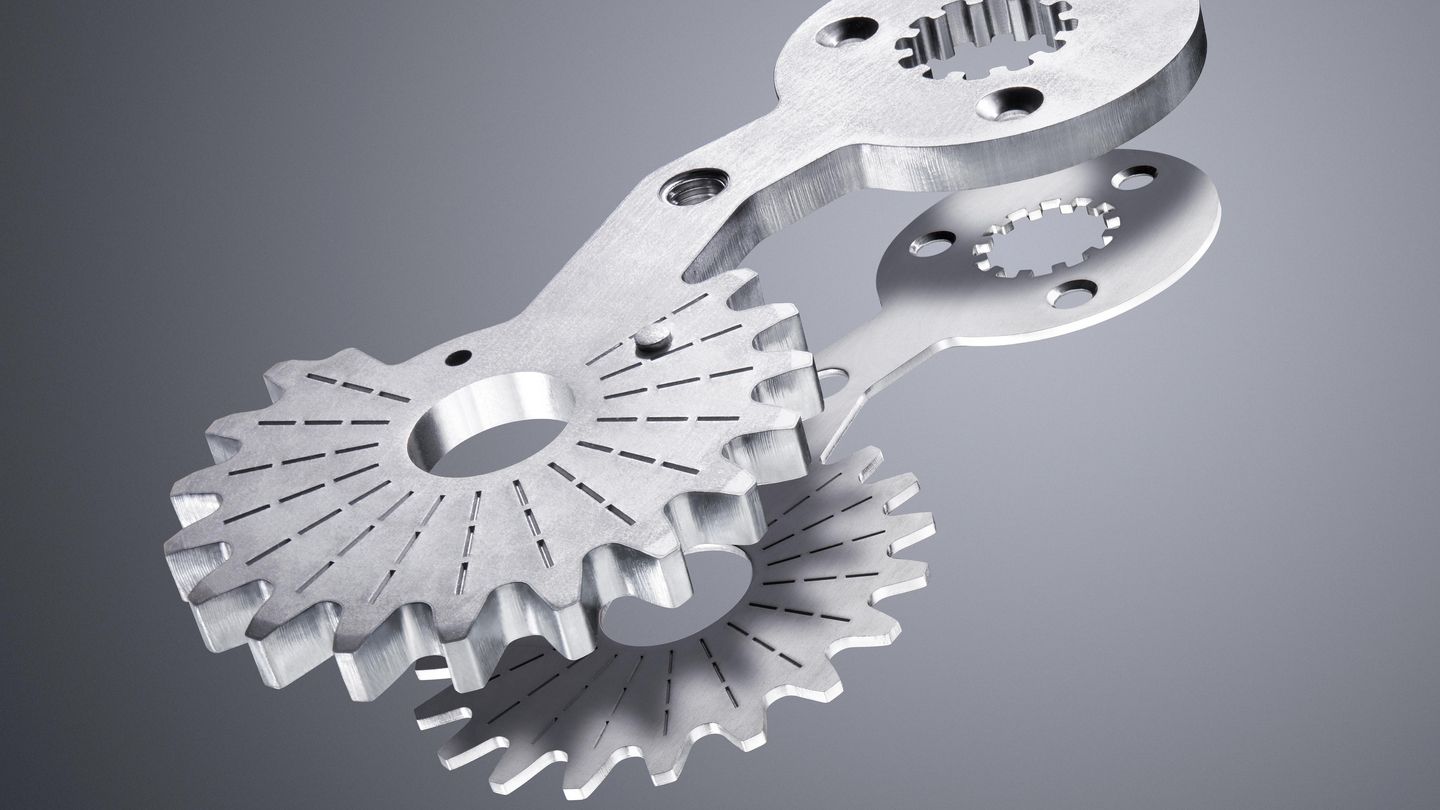

The TruMatic 6000 is a versatile machine with sophisticated laser and punching technology. The powerful punching head and laser guarantee high productivity and excellent quality. The clever laser concept and universal cooling interface provide outstanding energy balance. Due to the simple operating concept, you can produce parts up to 0.3 inches quickly and easily – and as a result of the intelligent software functions, with process reliability.

Equipment

Quality

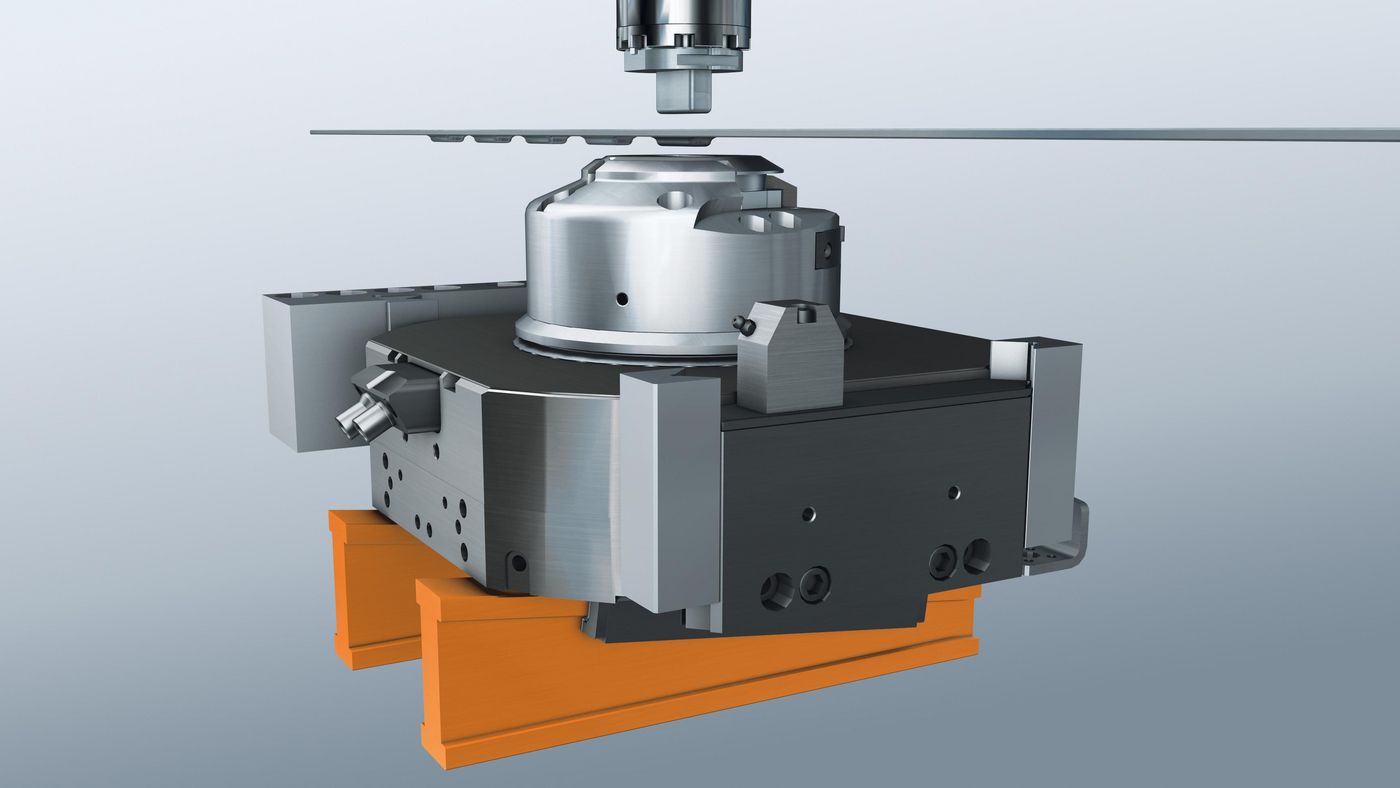

Descending die

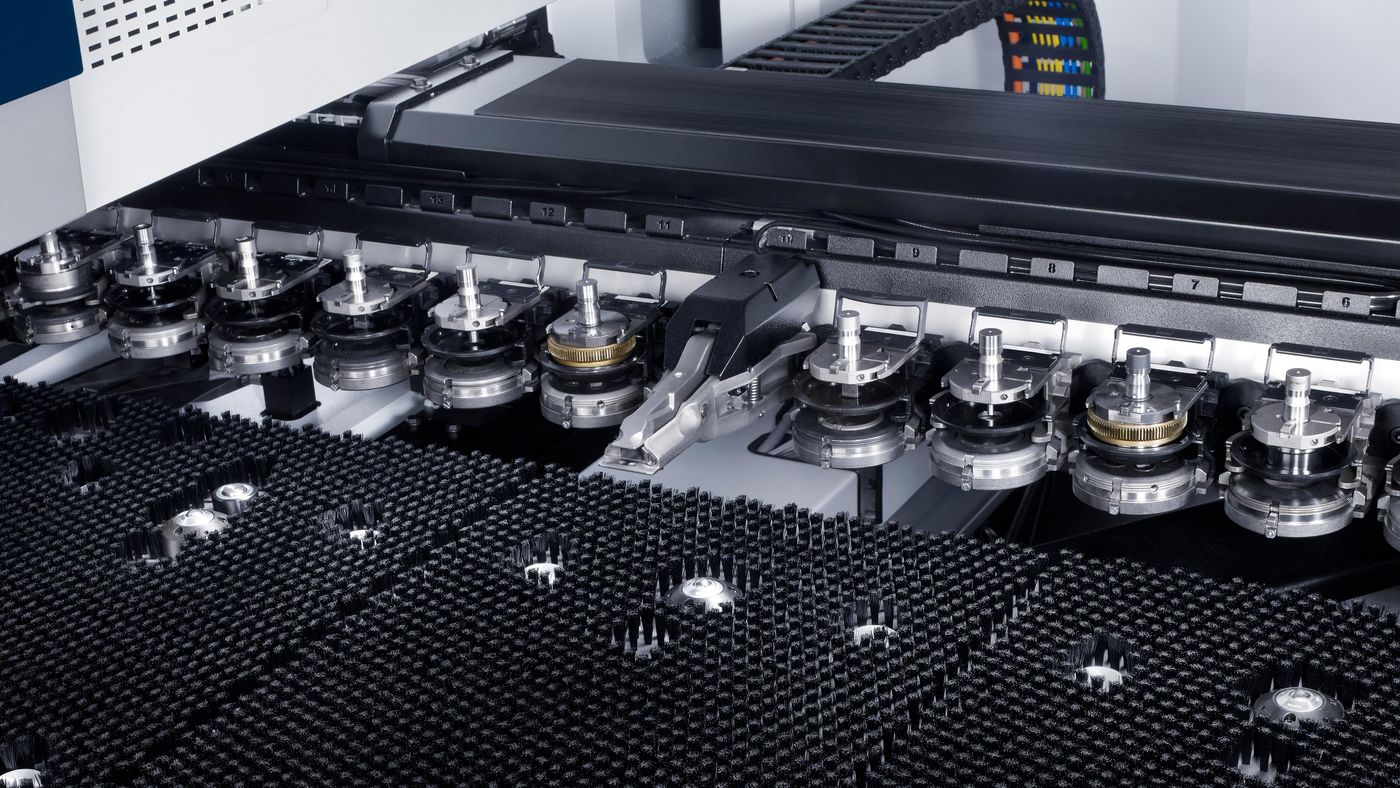

Ball tables or brush tables

Process reliability

Smart functions: smart load

Smart functions: smart unload

Smart functions: smart punch monitoring

Cost-effectiveness

Integrated flattening

Flexibility

MobileControl app

With the MobileControl app from TRUMPF you can operate and monitor your machines easily and with flexibility as the app transmits the interface of the standard control panel onto the touch screen of your tablet PC. In addition to the static control panel, you have another option for monitoring and controlling your machine.

Tools

Offsetting roller tool

MultiBend Extended

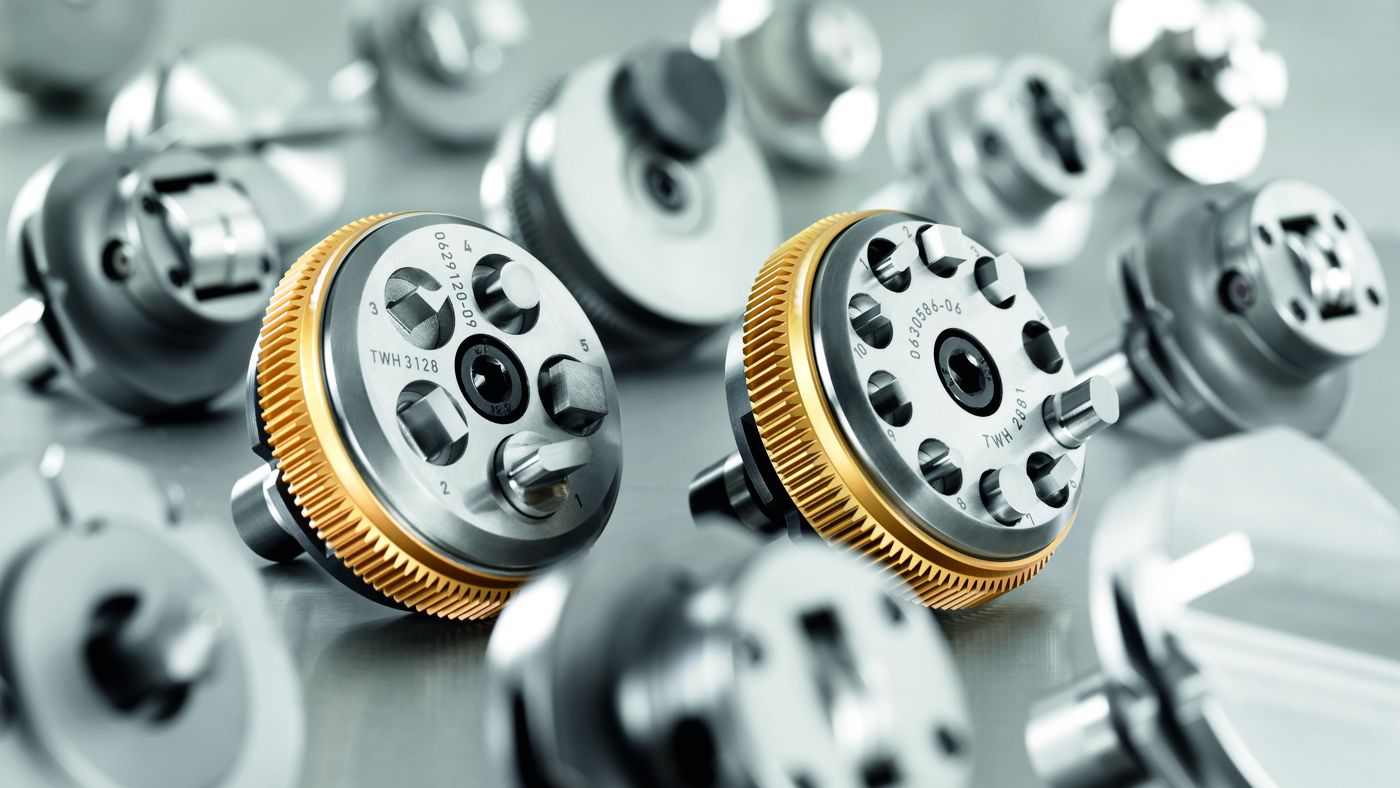

Ejector MultiTool

Punching tools at a glance

TRUMPF offers the world's largest range of punching tools on the market. You will find the perfect solution for every punching and forming application.

Automation

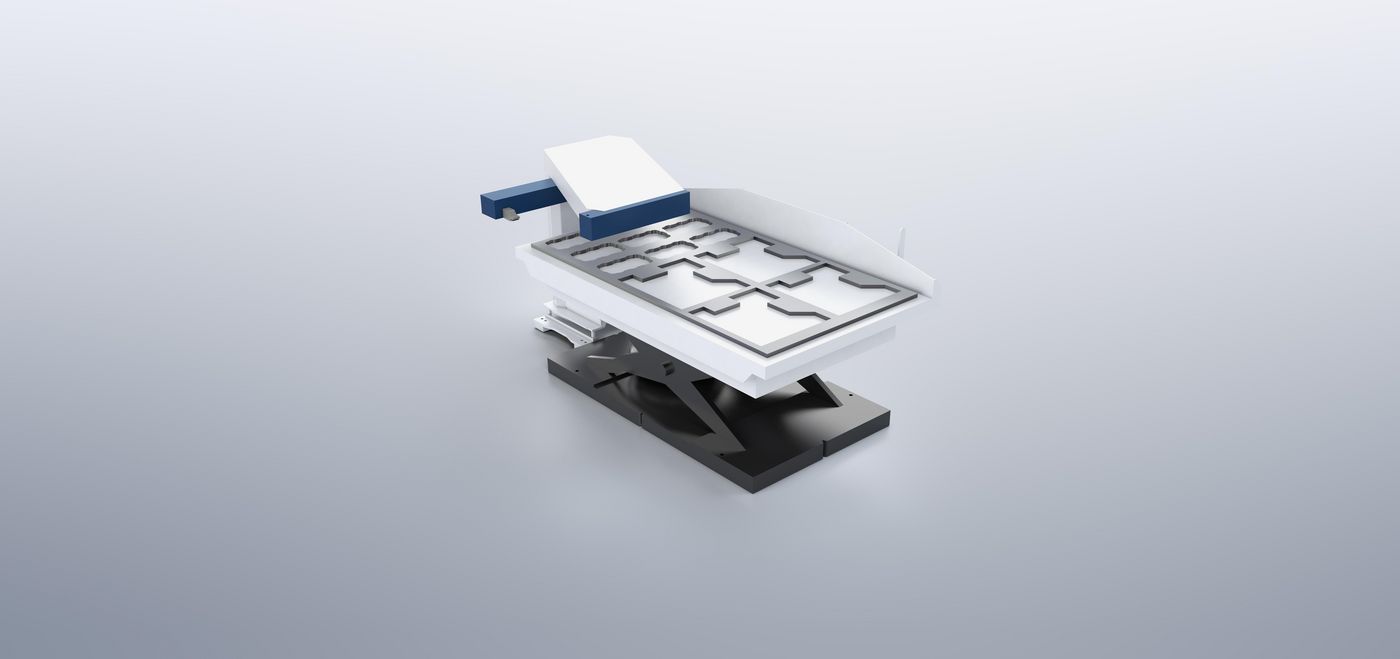

Loading + unloading + sorting

Sorting

Disposal

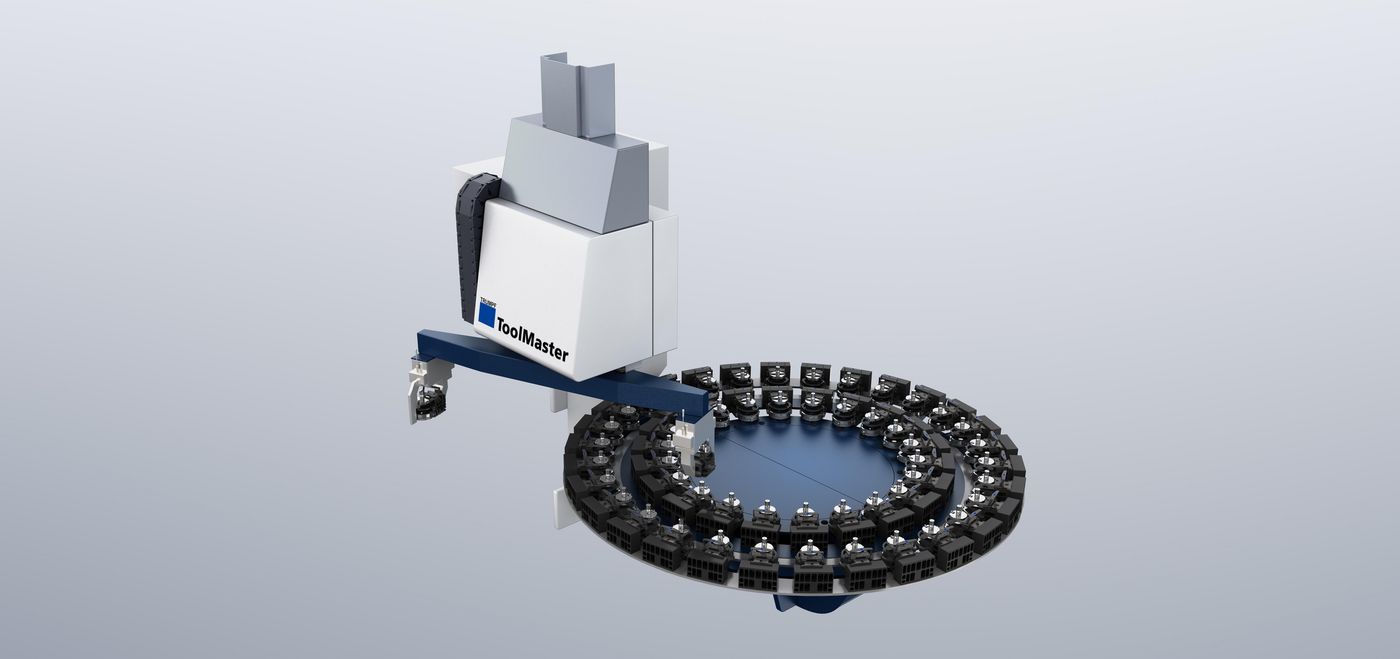

Tool handling

The ToolMaster provides space for 40 to 70 tools which are automatically positioned in the linear magazine of your machine. This means you can complete even complex orders with numerous tool changes quickly and automatically.

Send forespørsel

[contact-form-7 id="11912" title="Forespørsel"]