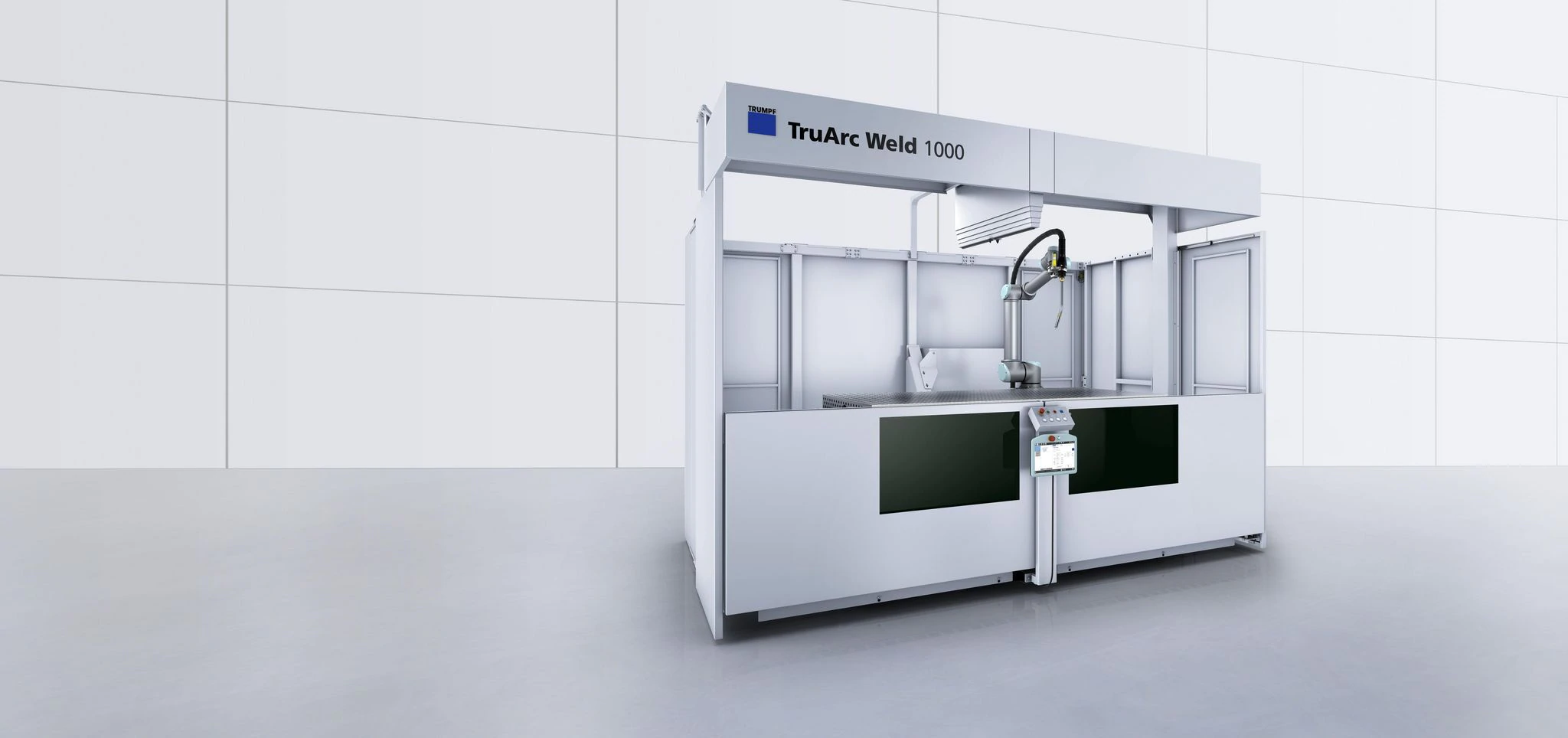

TruArc Weld 1000

Quick programming, safe welding

The welding cell is a fully equipped machine tool, tested by the Technical Supervisory Association (TÜV) and certified with CE. This includes an exhaust system, housing with anti-glare protection and safety equipment in line with TRUMPF standards. You can launch, program and operate the welding cell with very little training – video tutorials will do the job. You can utilize the welding cell in one- or two-station operation, depending on the component and lot size. This means, for example, that you can either process a larger component or smaller components in larger batches parallel to production.

Technical data

Equipment

Combination of intuitive operating unit on the welding torch and simple programming directly at robot control for minimum programming times. The design of the machine's central operating unit is simple and clear.

Collaborative robot UR10e with six axes and force moment sensor. The linear axis positions the robot on the left or right.

Safety cabin with integrated exhaust system, automatically opening anti-glare protection and lighting. The extendible partition wall divides the work area for two-station operation if required.

High-performance welding equipment from Fronius: TPS 320i C PULSE welding source including welding package PMC, ultra-slim 350 ampere torch and external wire feed system.

3D welding table by Demmeler with hole pattern D16 in a 50 x 50 mm grid and hardened surface. The table's dimensions are 2000 x 1000 x 100 mm.

User-friendly loading of heavy and large components and devices is possible with this option. To do so, the cab cover is opened individually over the two stations and the component is loaded into the machine interior by crane.

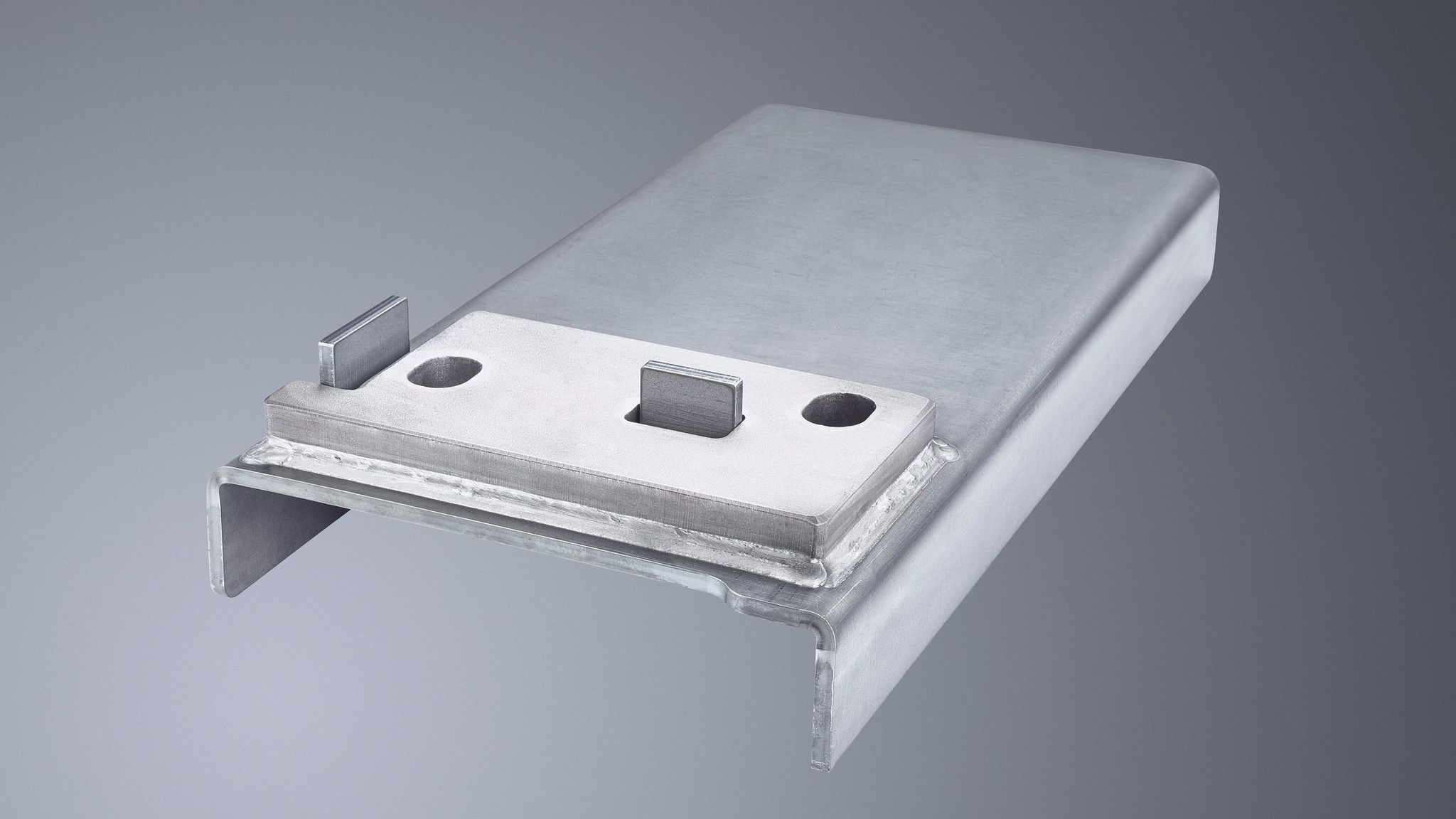

The optional technology package CMT welding ensures higher process reliability and energy-reduced welding with fewer weld spatters and little distortion with the TruArc Weld 1000.

Pendulum welding is particularly beneficial for thick sheet processing. You can prevent a lack of fusion with wide weld seams.