TruLaser Tube 3000 fiber

Economical even at low utilization

Whether you would like to insource quality, produce at short notice with more flexibility or develop new customers and markets: the TruLaser 3000 fiber is the machine for you – and it is ideal for first-time users or as a supplementary machine thanks to its easy handling.

Technical data

Equipment

Economic and easy to operate

High dynamics

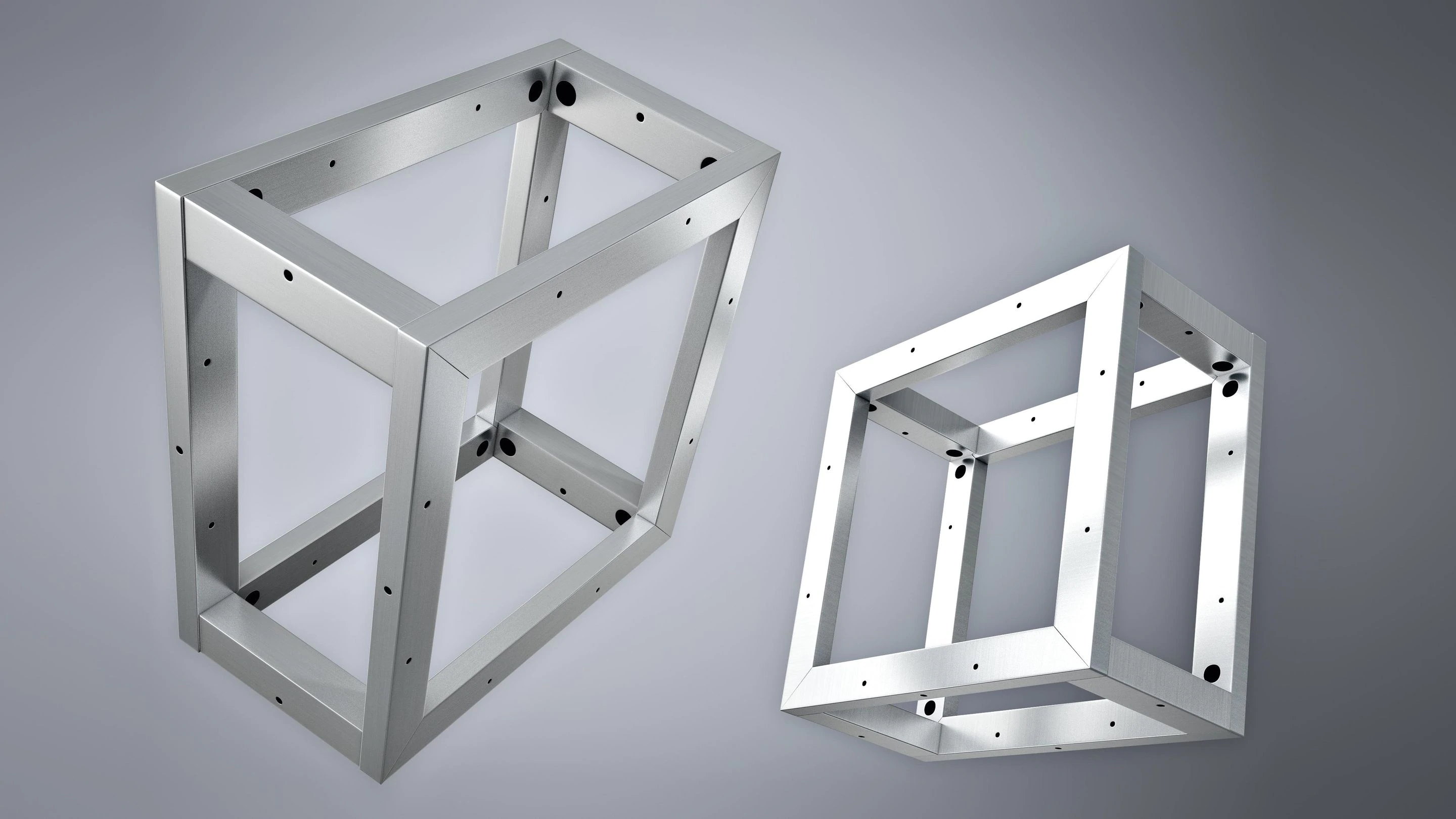

The rigid machine frame and precise tube guides simultaneously provide particularly quick processing and high quality in the finished part.

Good accessibility

The open machine concept is reflected in all of its elements - from loading to the machining process view to removal of the finished part.

Minimum setup times

No setup times or setup errors in the standard clamping range - produce without changing the setup thanks to the clamping system for the TruLaser Tube 3000 fiber.

FocusLine

No more adjustments by hand: the FocusLine control mechanism keeps the focal position of the laser constant and automatically adapts it to the material.

Adaptive clamping system

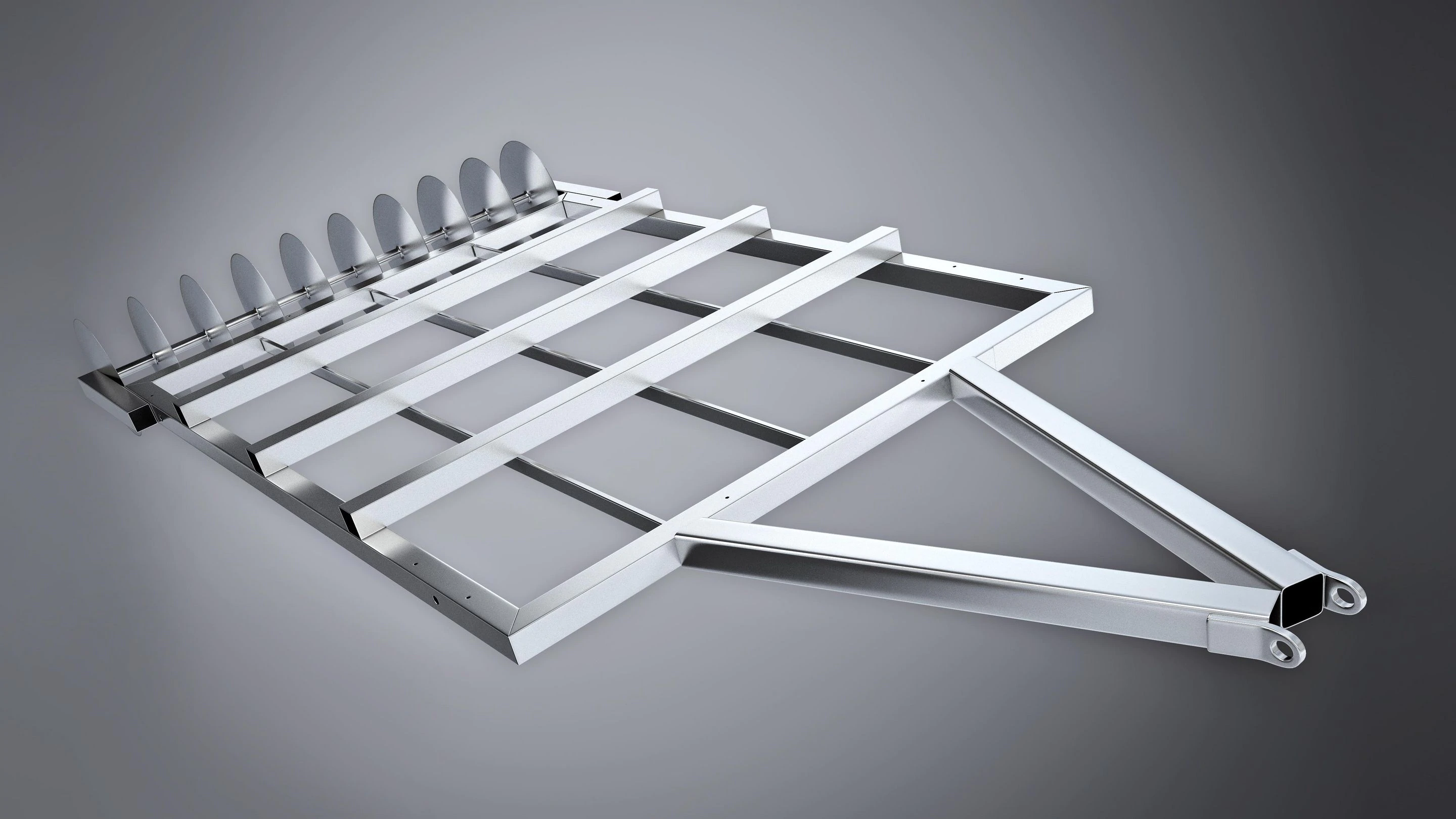

Are L- and U-profiles part of your production? You can also process open profiles quickly and with precision thanks to the adaptive clamping system

Precise tube guide

Whether it's for longer or shorter parts - your tube is optimally guided and in most cases, you can work without any microjoints at all. This means that rejects are a thing of the past.

AdjustLine

Is your material rusty or otherwise adversely affected? You can still reliably cut it without restrictions - thanks to AdjustLine, no expertise needed, easy to activate.

SeamLine Tube

Would you like to bend the tube or produce visible parts? The weld seam is always at the same place on the finished part with SeamLine Tube - a clever function which makes further processing much easier. Camera detection takes just seconds.

Magnetic coupling

The magnetic coupling with bellows protects the cutting head. In the event of a collision, the cutting head deflects, which prevents structural damage. It can then be moved manually into the starting position again. This means that production can be resumed after a short time.

Robust design

The machine has a robust construction - from the frame to the operating panel: this means the quality of your work remains consistent.

Single-cutting-head strategy

With the single-cutting-head strategy, you can process multiple material types and thicknesses with the laser without changing the cutting head.

ControlLine

ControlLine provides ideal part quality thanks to perfect distance regulation - and prevents damage to the cutting head.

Dot Matrix Code

You can use a code to clearly identify your parts. You save time and always know which order your part belongs to - improving throughput times.

Automation