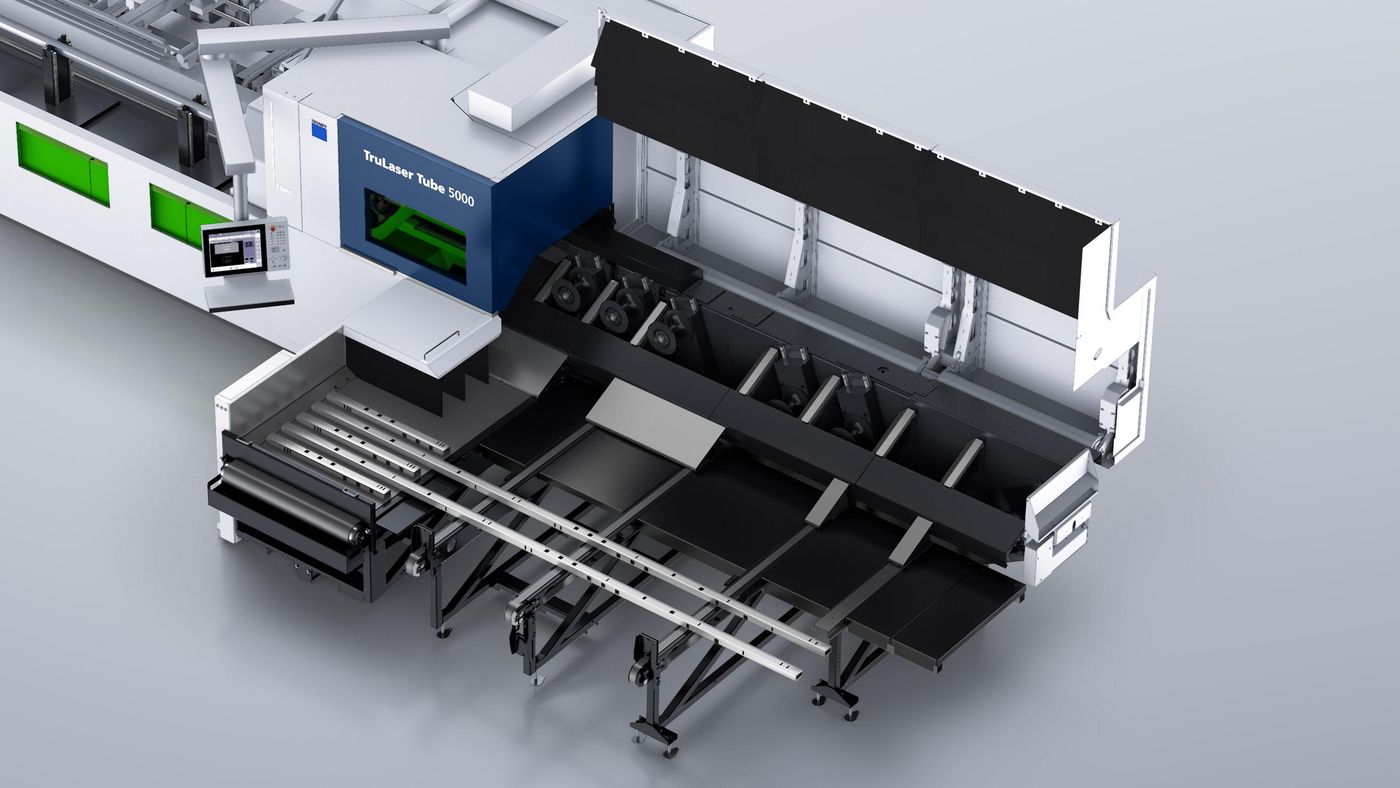

TruLaser Tube 5000 fiber

The fastest tube cutting machine in the world

The TruLaser Tube 5000 fiber takes advantage of the strengths of solid-state lasers in a way that no other machine ever has before. For you as a user, this means short processing times for a large range of possible tubes and profiles.

Equipment

Autonomy

Smart profile detection

SeamLine Tube

Sensor system

Your machine is ahead of the game: sensors detect whether or not a part has been correctly ejected.

Speed

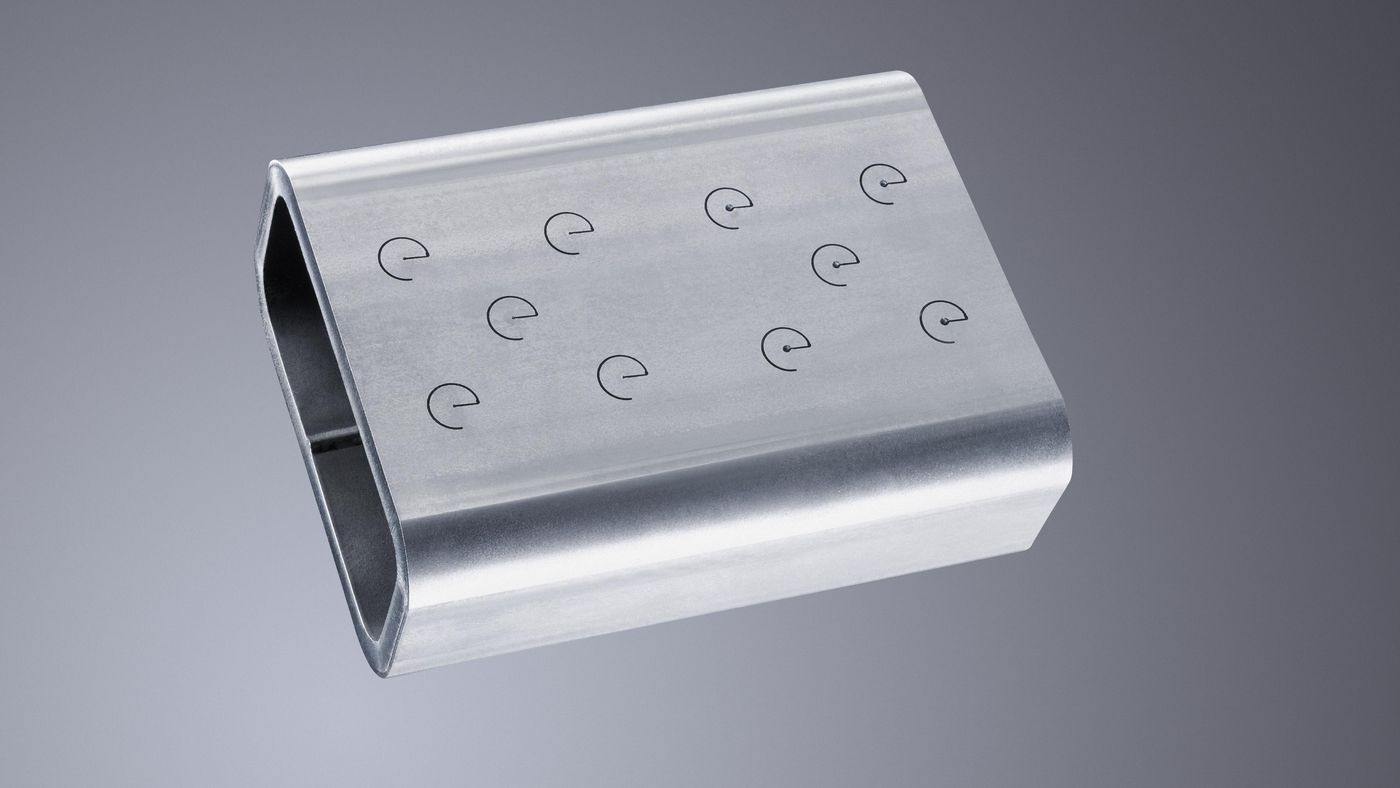

RapidCut

With RapidCut, the high feed rates of the solid-state laser come into their own even on smaller contours. Particularly on thinner materials this is a huge productivity advantage for your production.

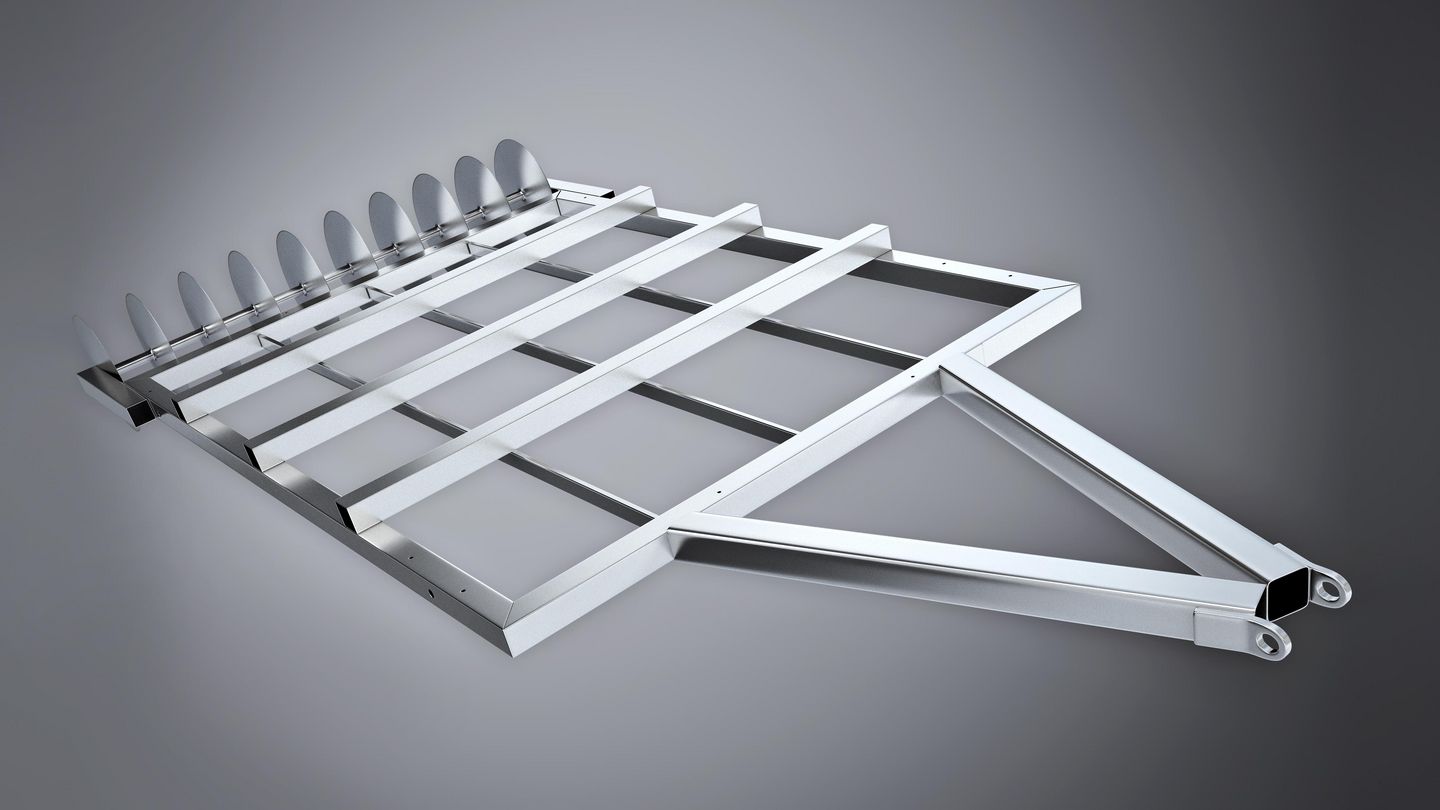

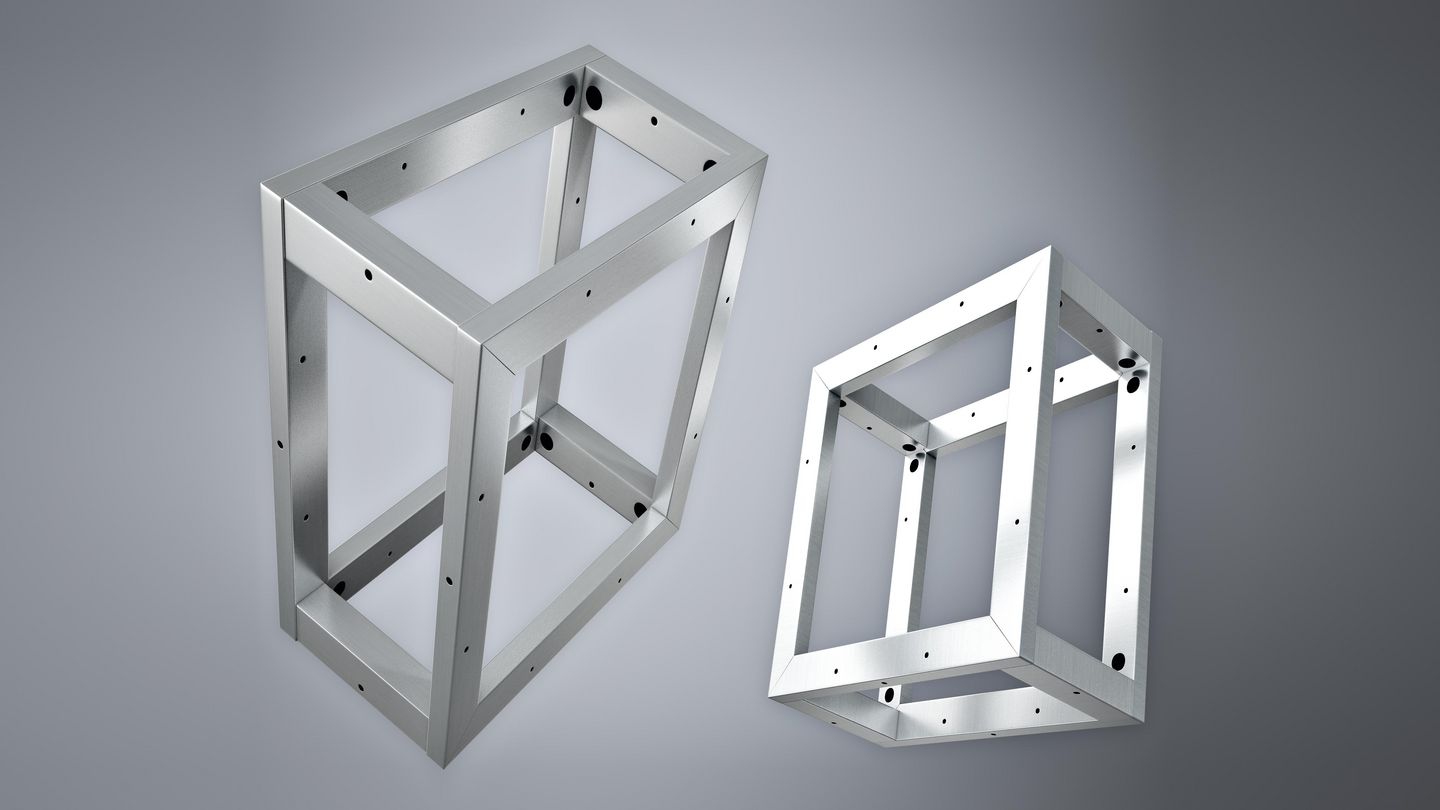

Expand your processing spectrum

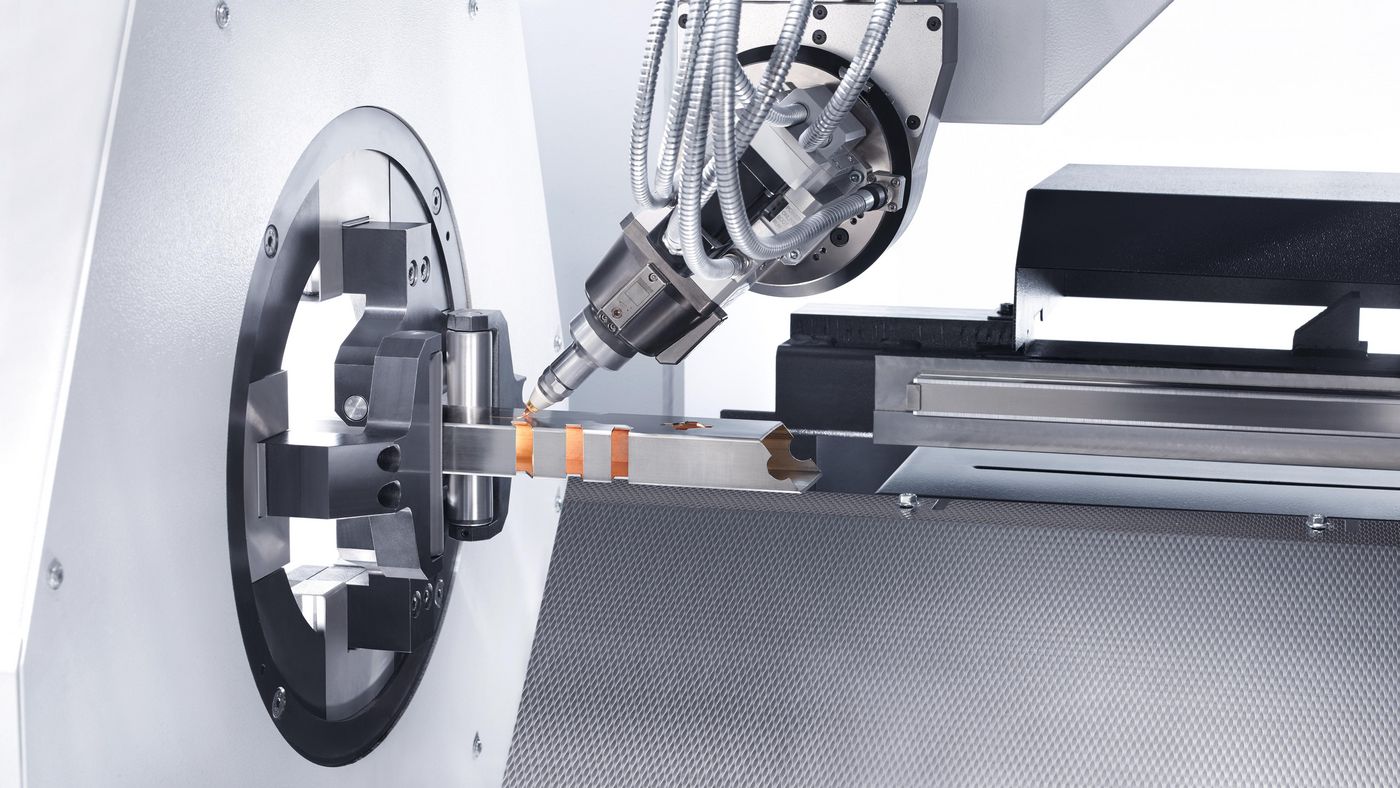

Bevel cuts of up to 45 degrees

You can expand your range of parts with high-quality bevel cuts of up to 45°.

Quality

FocusLine

No more adjustments by hand: the FocusLine control mechanism keeps the focal position of the laser constant and automatically adapts it to the material.

PierceLine

PierceLine controls and monitors the piercing process. The piercing process is ended as soon as the material is completely cut through. This leads to more accurate results and shorter processing times.

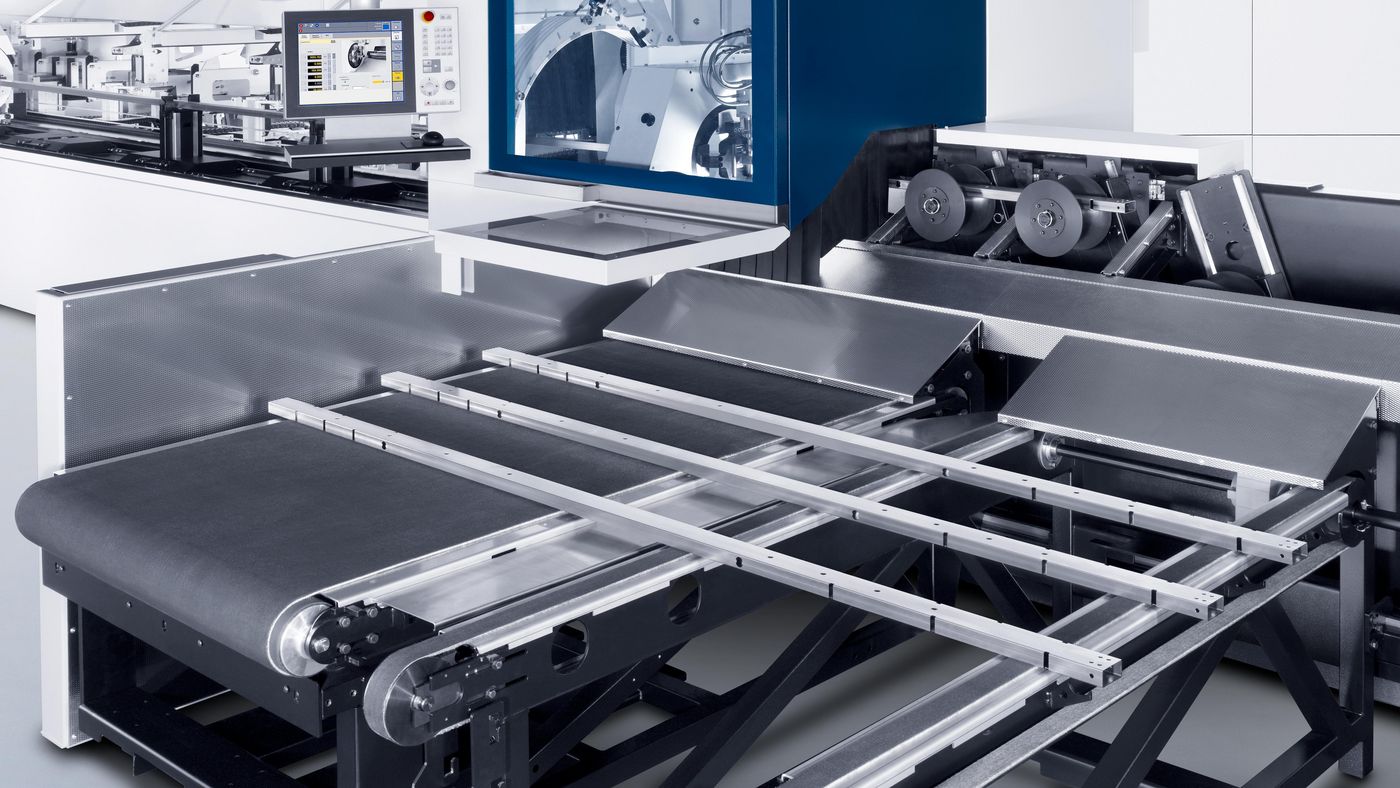

Conveyor tables

Conveyor tables at an ergonomic height make it easier to unload tubes and profiles. They also serve as a practical material buffer.

Automation

Loading

Loading

With the LoadMaster Tube loading unit you can minimize your setup times. The practical bundle space automatically provides the unprocessed material. It is also possible to set up the LoadMaster at the front of the machine. This enables you to adapt the layout of the machine perfectly to your material flow.