Produktbeskrivelse

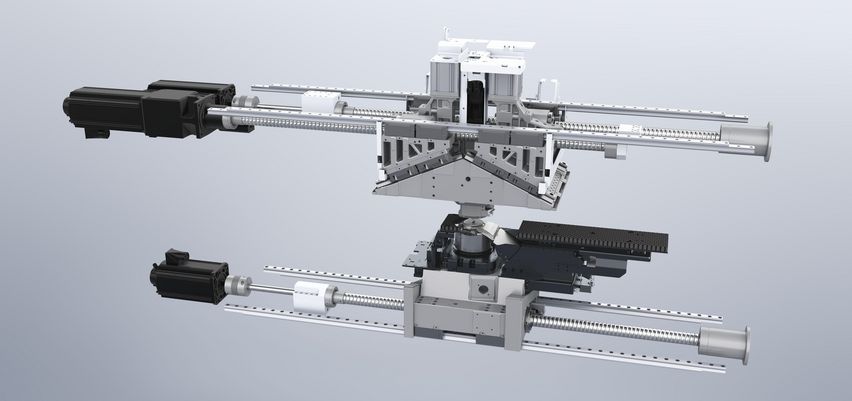

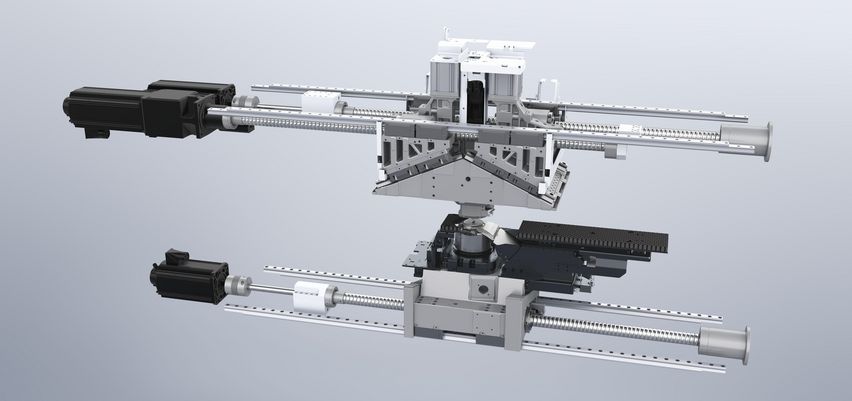

Compact and dynamic – the patented Delta Drive takes away the need for the sheet and support table to move in the Y axis because it enables the punching head to «fly», i.e. to move back and forth, for the very first time.

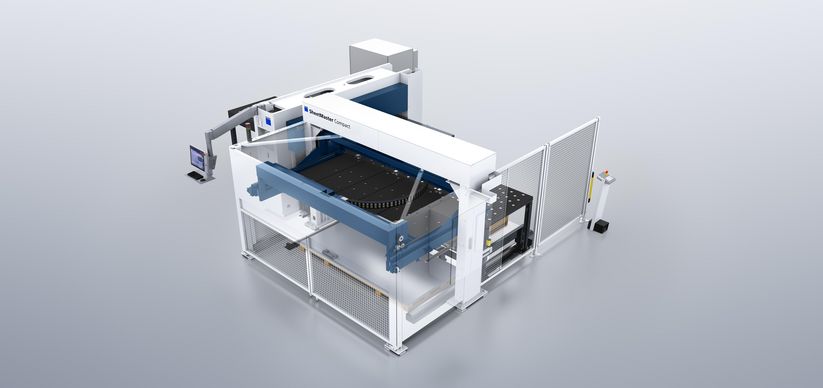

The compact entry-level machine TruPunch 1000 is extremely flexible – it can be automated and upgraded to a space-saving punch laser production cell in line with your business development.

.

Compact and dynamic – the patented Delta Drive takes away the need for the sheet and support table to move in the Y axis because it enables the punching head to «fly», i.e. to move back and forth, for the very first time.

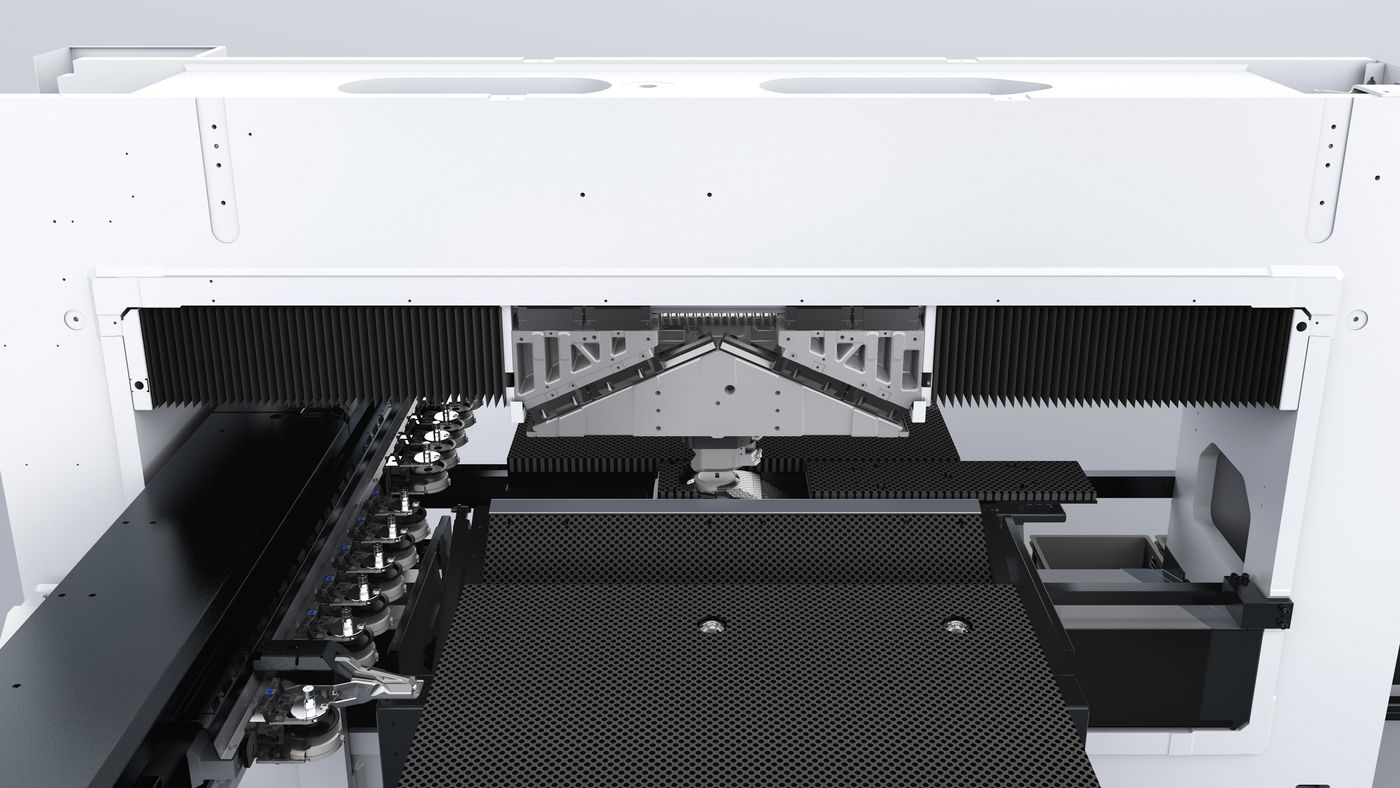

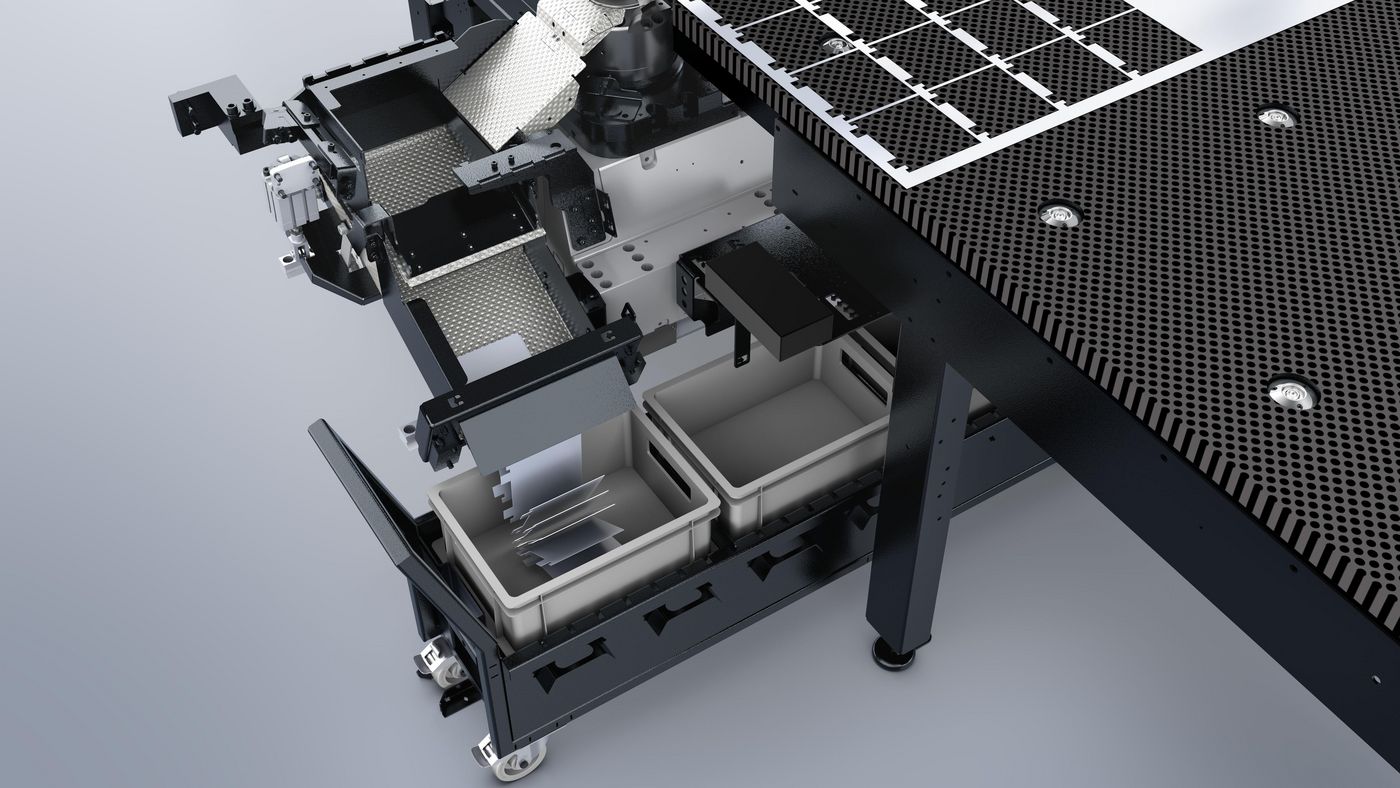

Your machine automatically sorts parts up to a size of 180 x 180 mm. Finished parts go through a chute into an intermediate buffer storage. There are up to four different boxes under the machine. The intermediate buffer storage moves to the correct box and adds the parts to this.

Before a tool change, this function checks whether a hole has actually been punched in the sheet. In this way, the machine detects at an early stage when punches are broken, and can pass this information on to the operator. The smart punch monitoring function therefore avoids rejects, especially during night or weekend shifts.

The chip conveyor can be used to automatically transport punching slugs into a container.

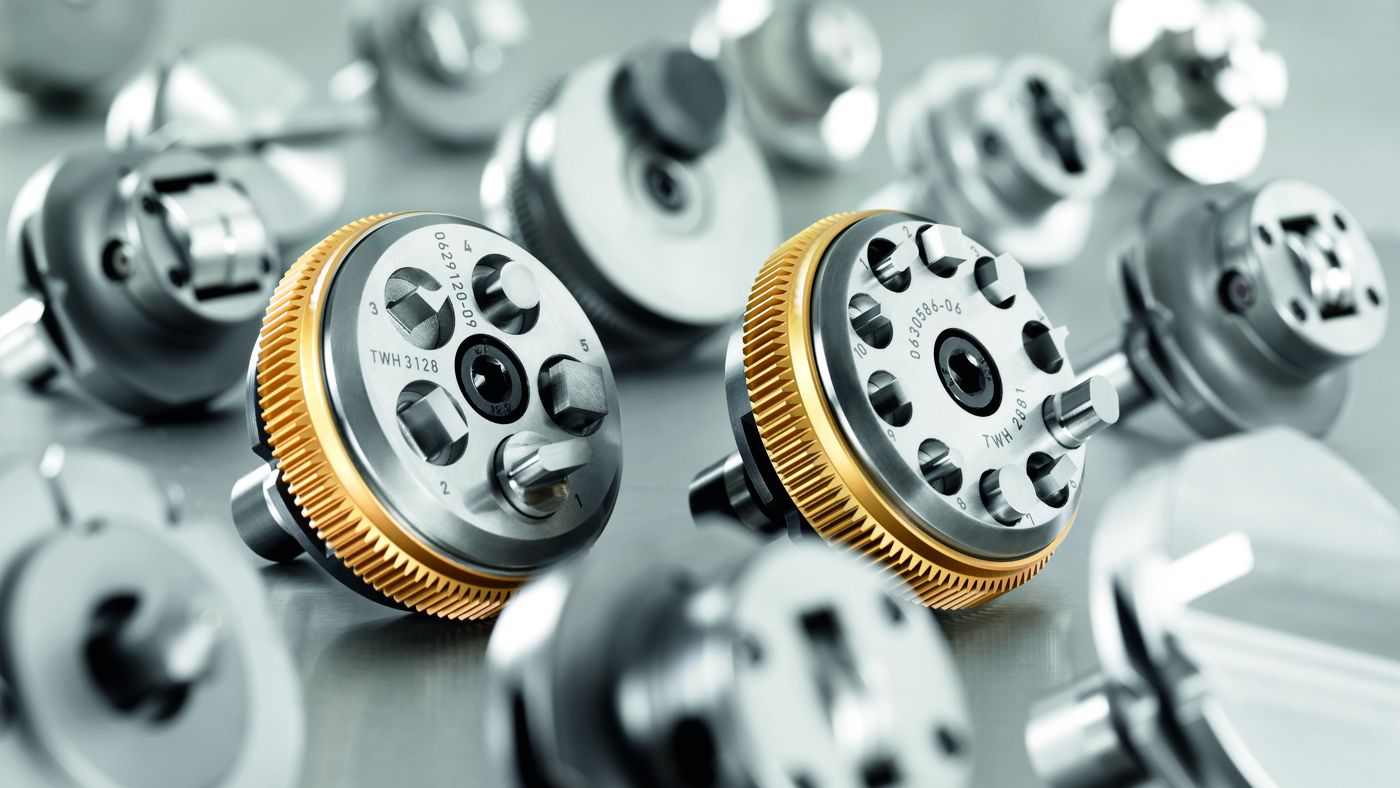

You can boost the productivity of your punching machine with a tool adapter for up to ten inserts – in particular for small punching operations.

90° bends of different lengths up to 2 in.: When working with the MultiBend, there is no need for an additional operation on the bending machine.

TRUMPF offers the world's largest range of punching tools on the market. You will find the perfect solution for every punching and forming application.