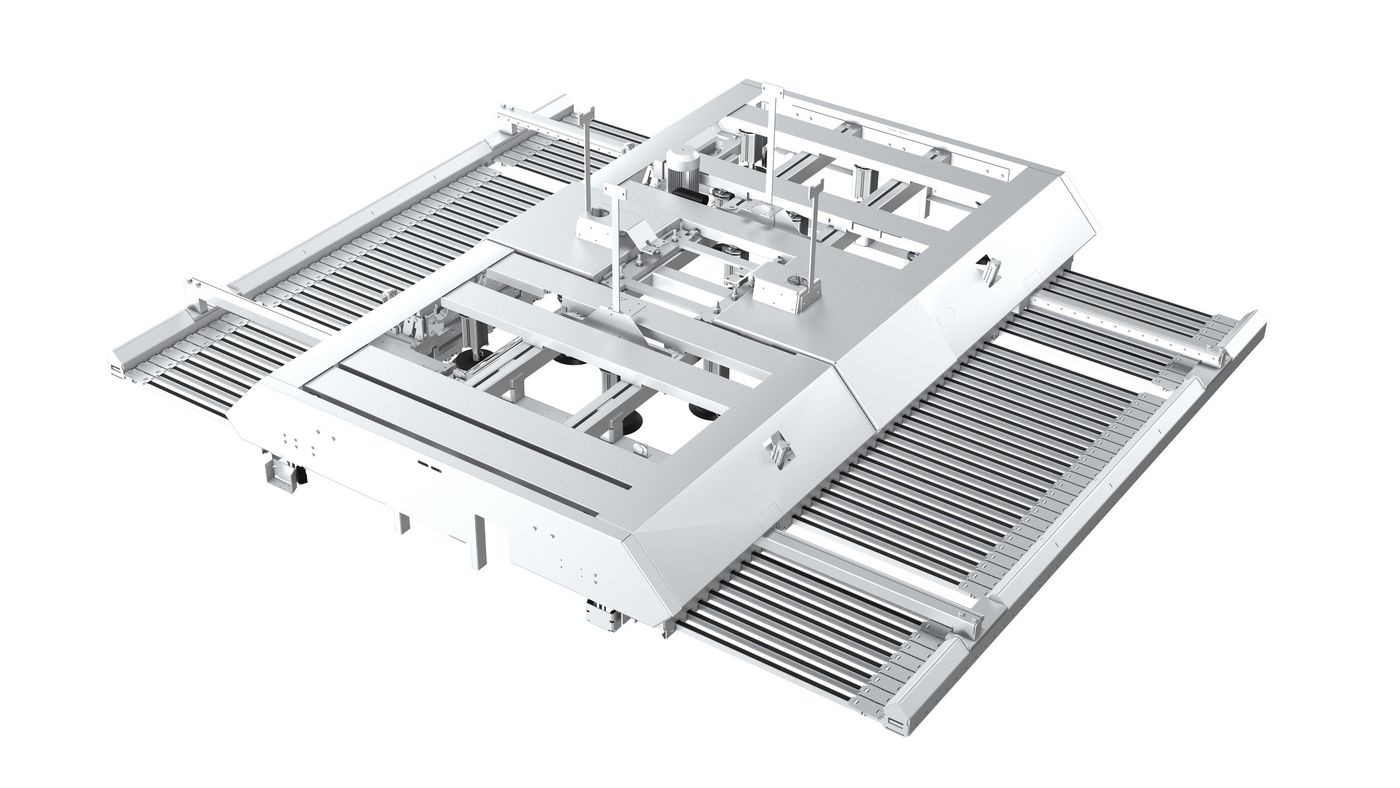

LiftMaster Store

Fastest storage connection

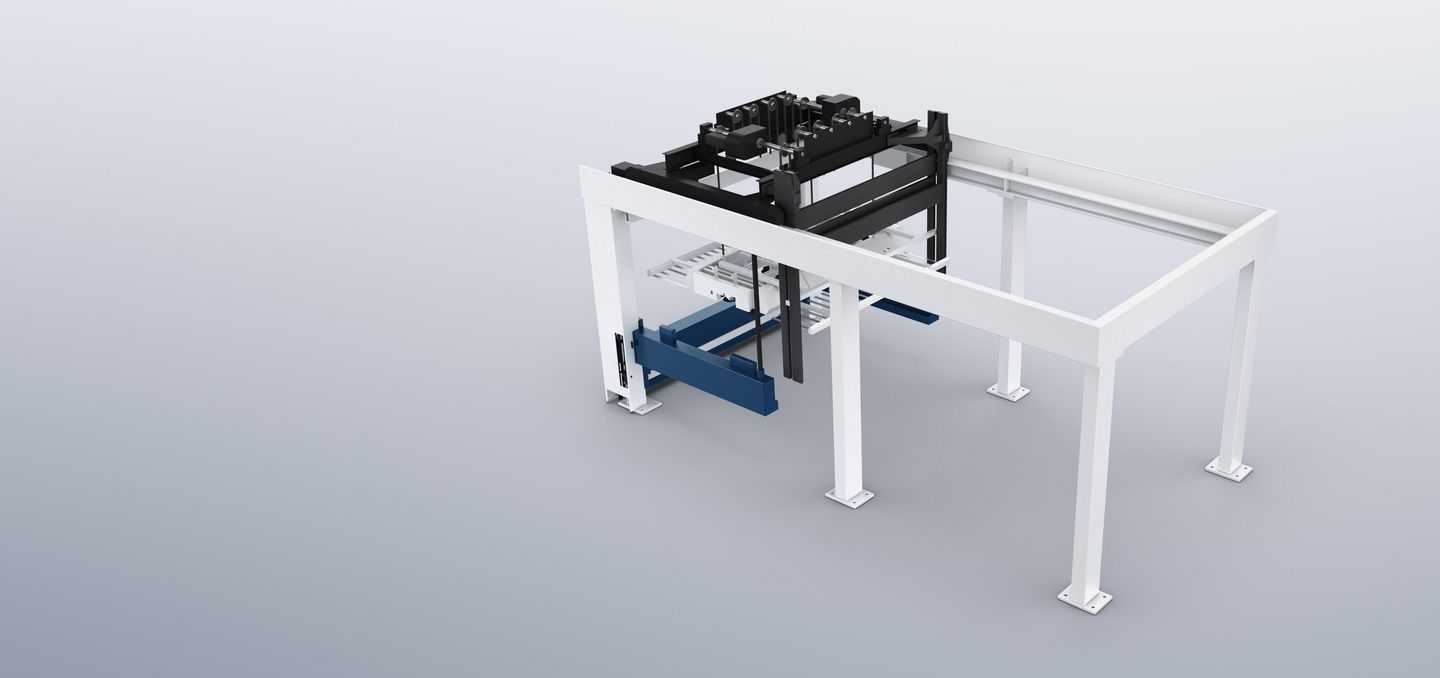

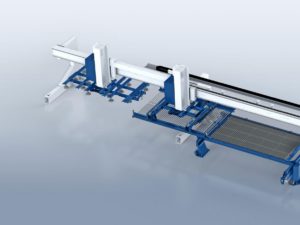

The frame solution, LiftMaster Store, is directly connected to the store and requires minimal space. In return, it offers more latitude to design your production to meet your specific needs. Here, the LiftMaster Store is assisted by a number of tried-and-tested TRUMPF technologies. Examples include the suction frame with unloading rakes for automated loading and unloading, or the synchronous loader for increased productivity. With the independent pallet picker crane, the LiftMaster Store can quickly access pallets in the store. This makes it particularly well suited to automated scrap skeleton separation. Connection to up to three machines with multiple tool stations is possible with the LiftMaster Store Linear.

Storage connections

TruStore Series 1000

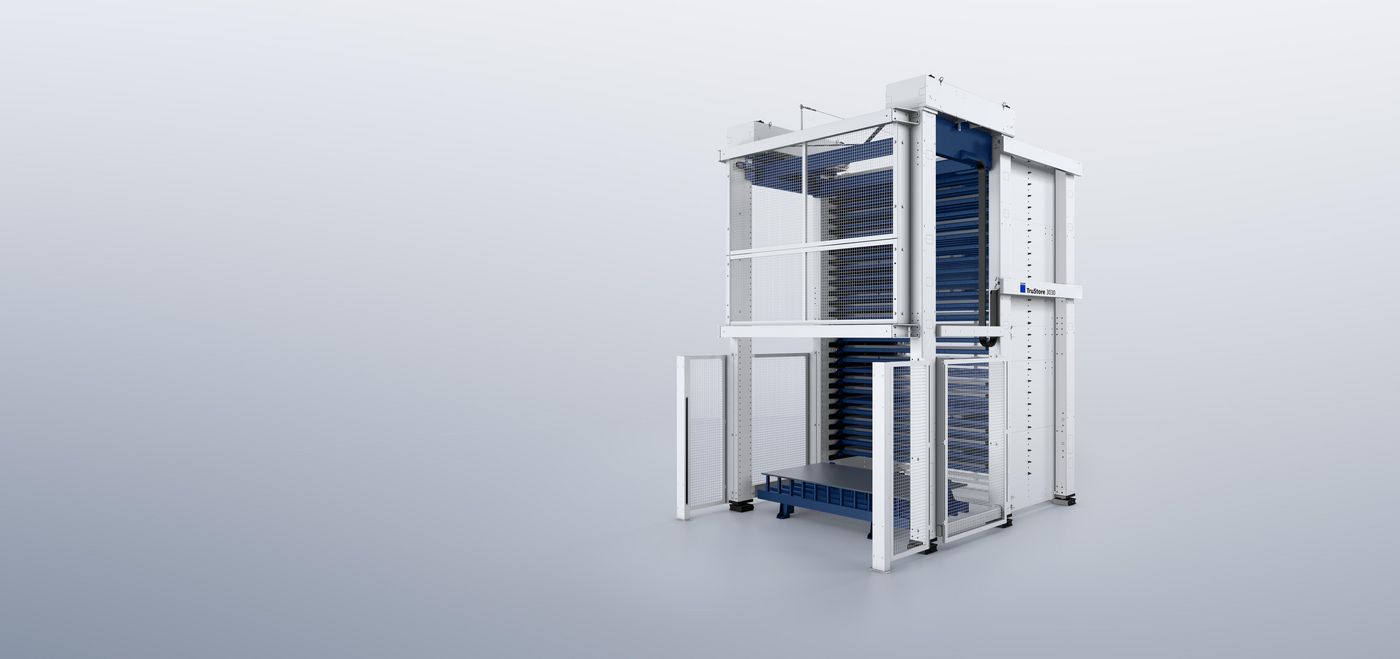

TruStore Series 3000

The most flexible storage

Equipment

Scrap skeleton separation

Suction frame/unloading rake

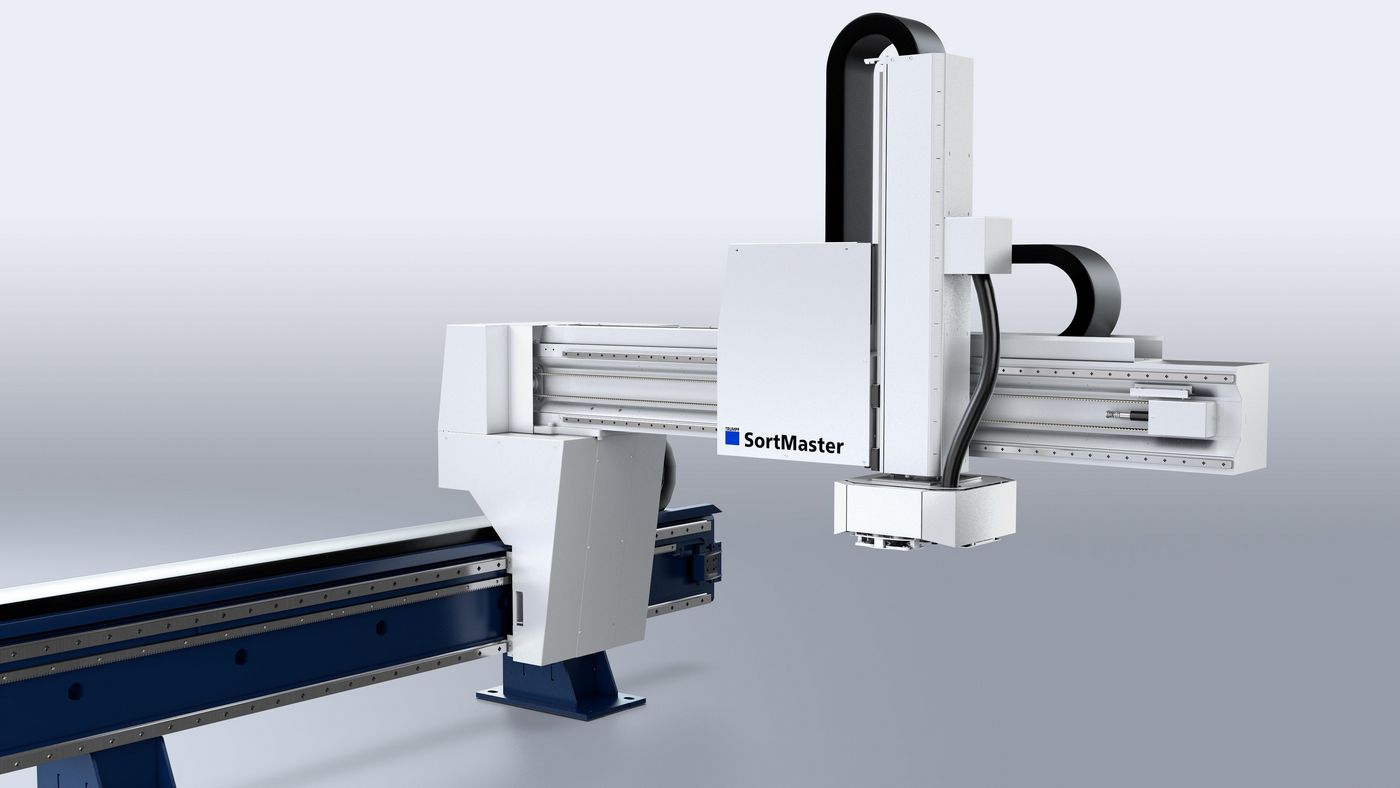

SortMaster

Multiple-machine connection

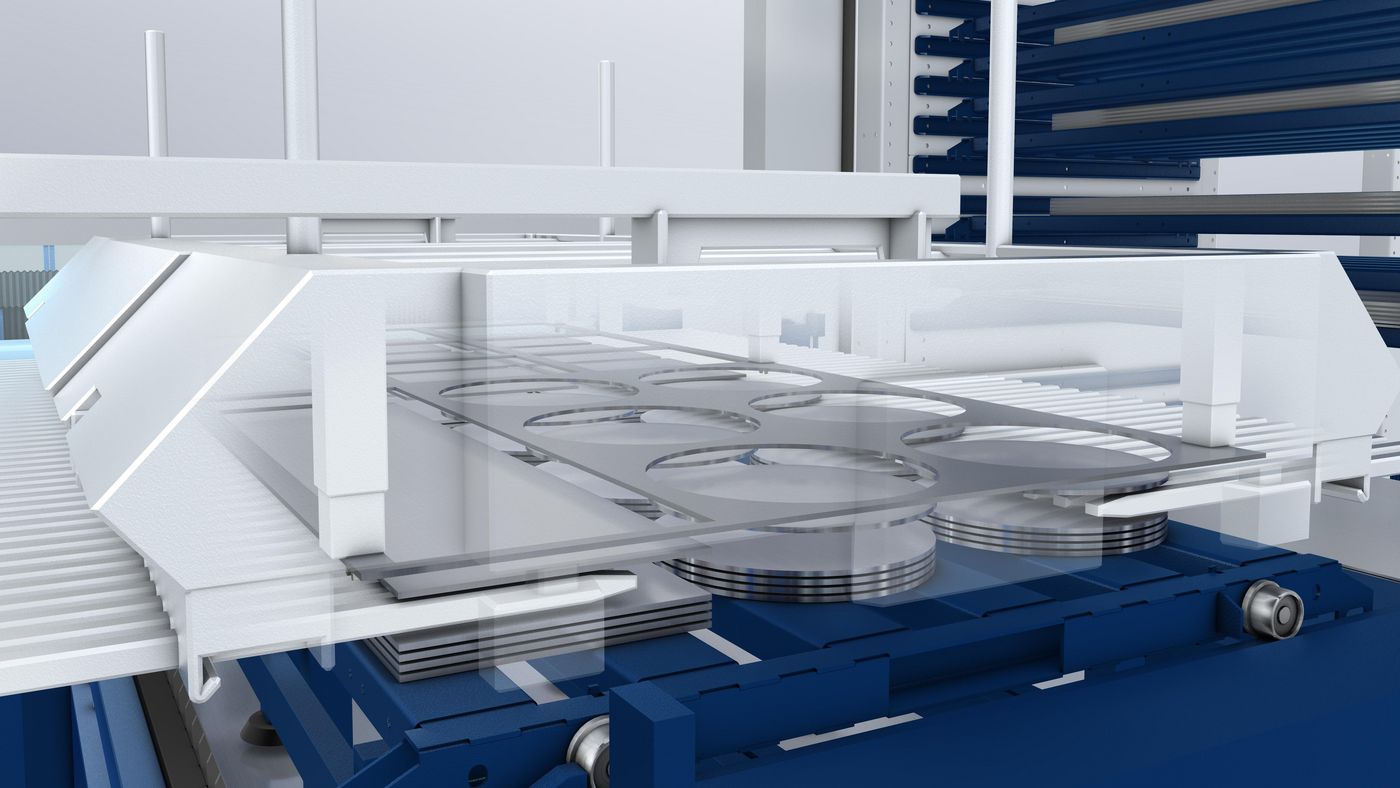

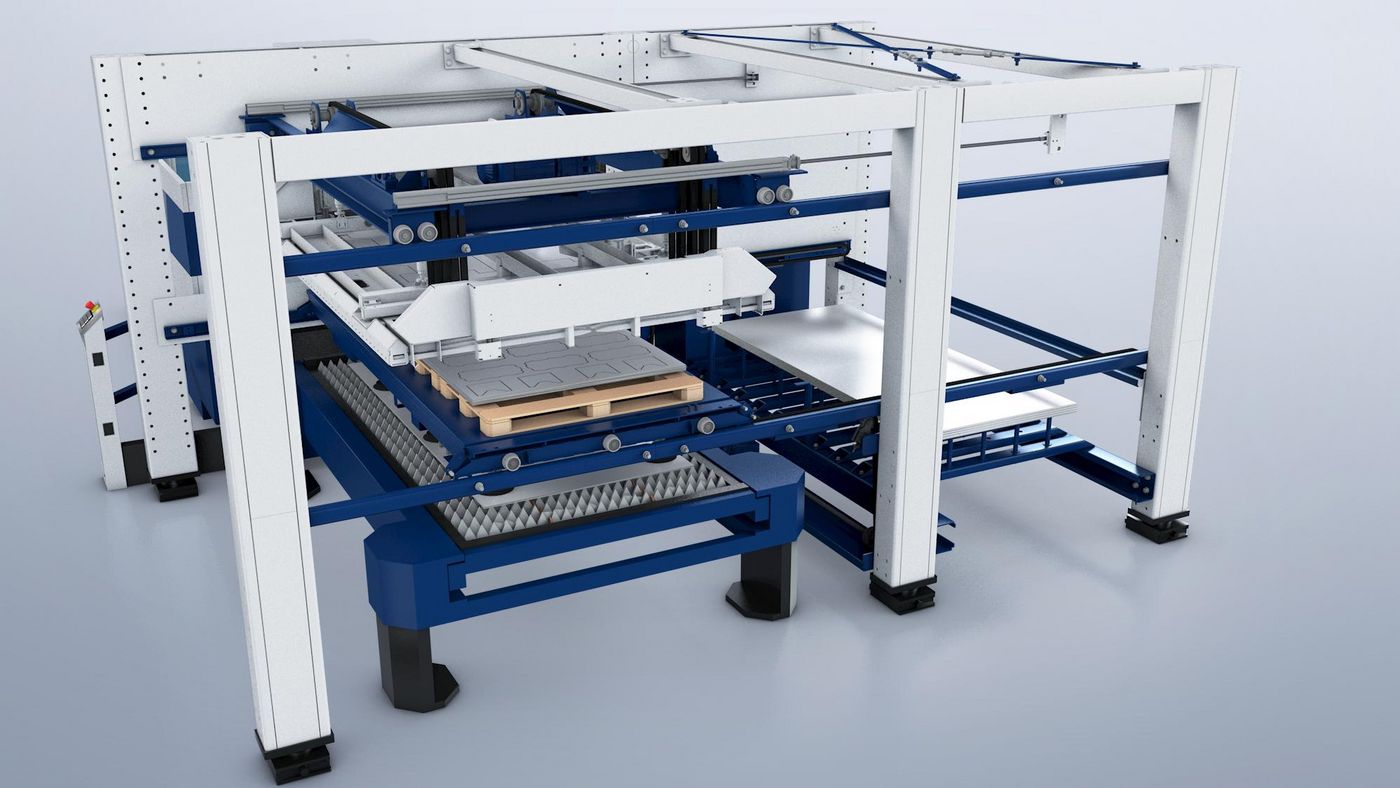

Synchronous loader

The synchronous loader has a suction frame that transports a finished part pallet, onto which the cut sheets are placed. It traverses horizontally between the unprocessed material table and the pallet changer.