TruBend Center 7030

Fully automatic panel bending

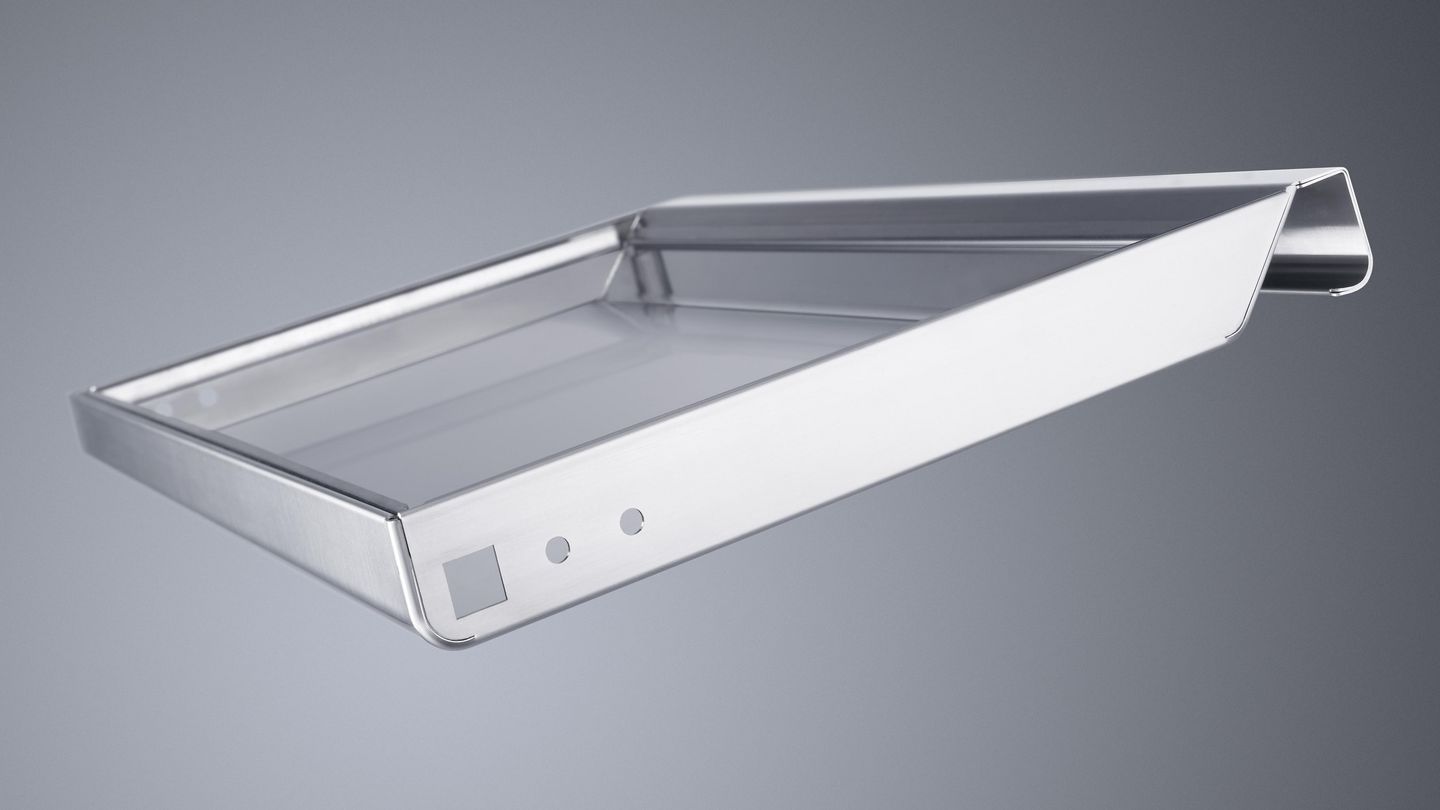

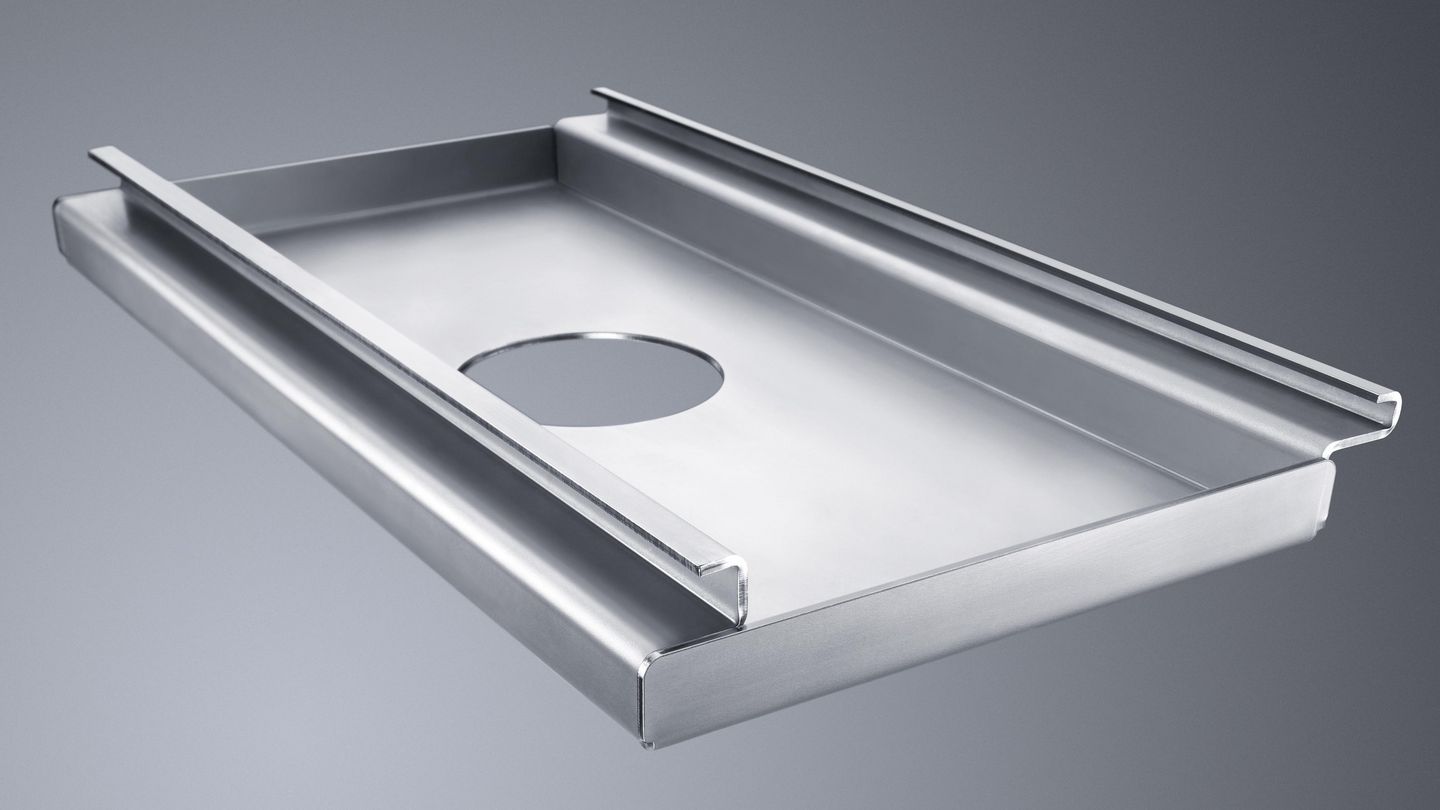

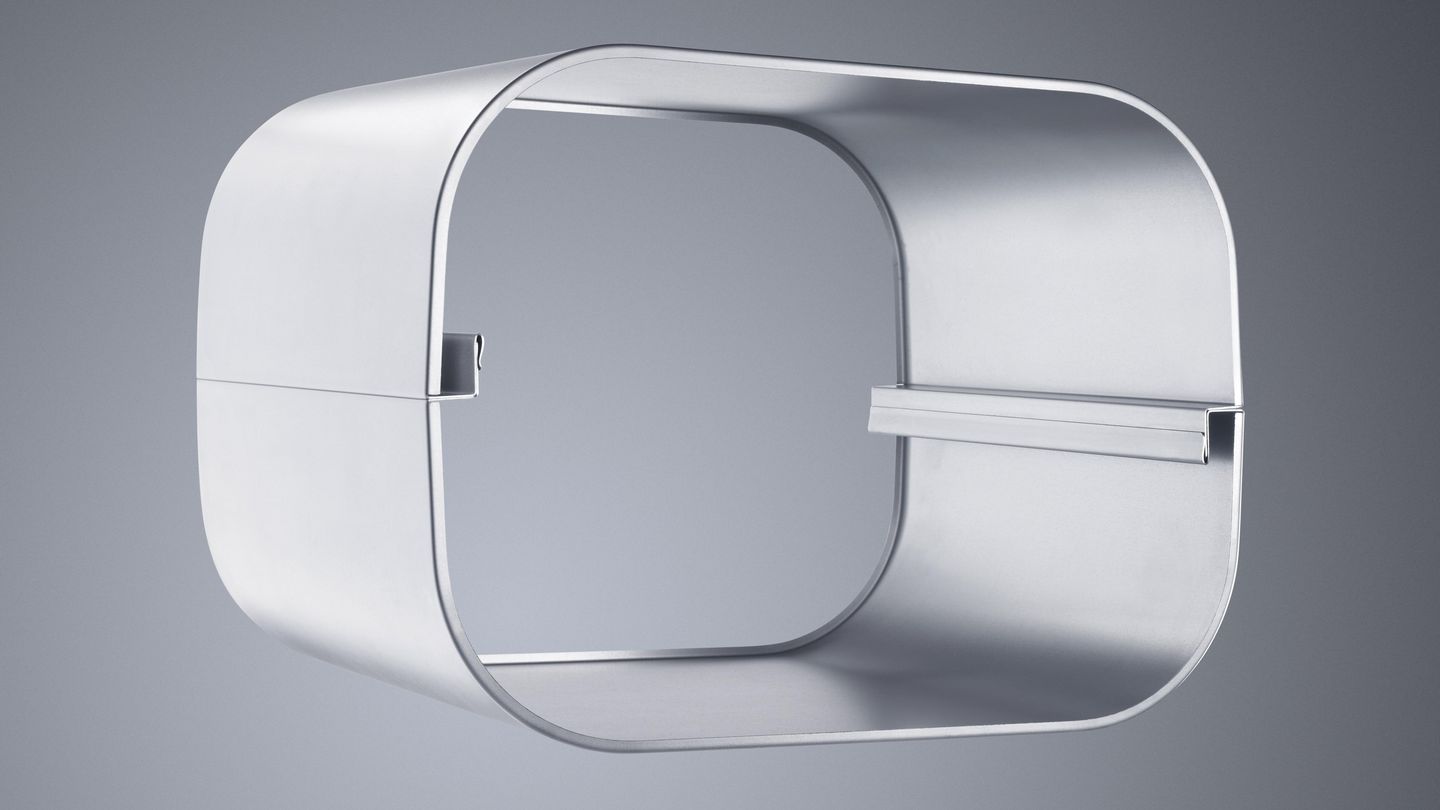

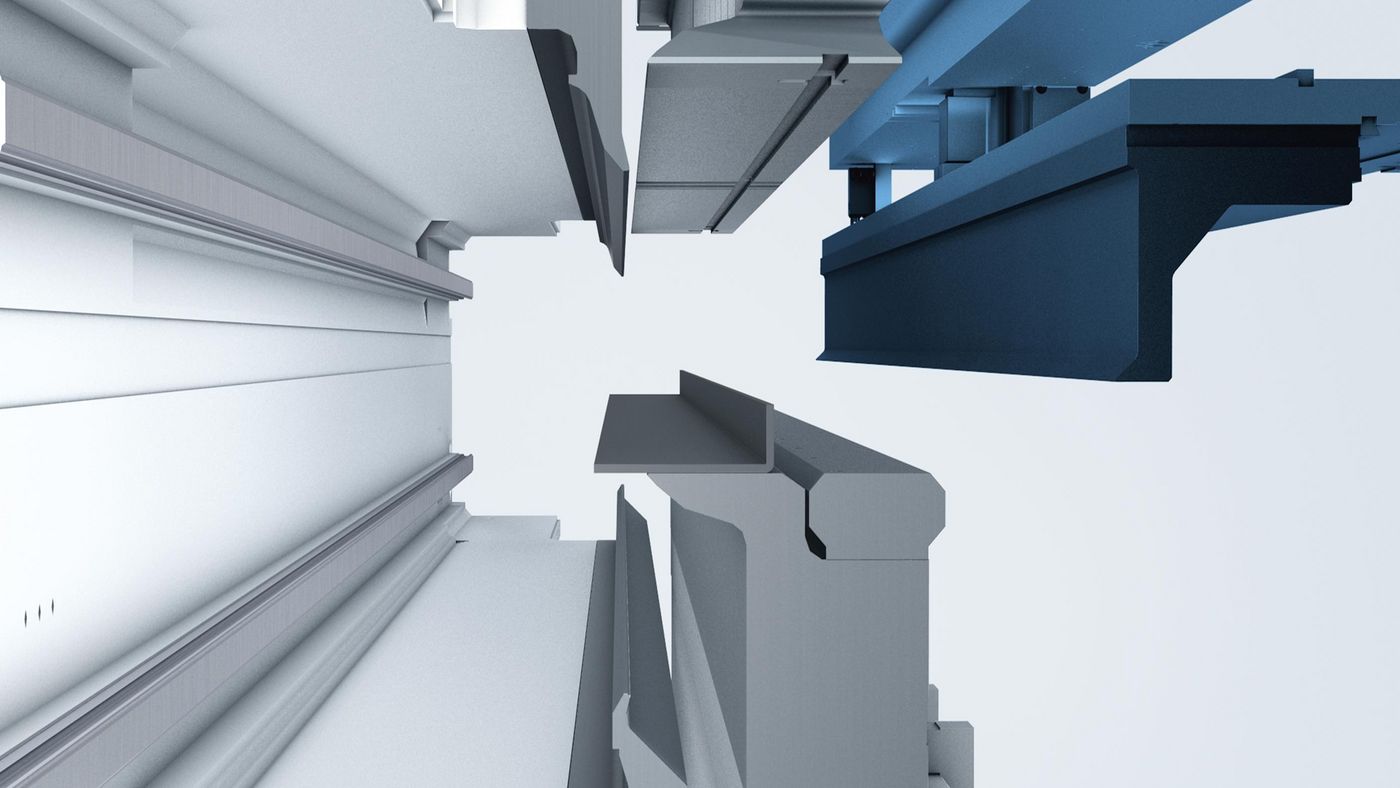

The TruBend Center 7030 sets the standard when it comes to flexibility and productivity during panel bending. Discover what is arguably the widest range of parts in this machinery category with completely automatic panel bending technology, and maximize productivity when producing complex workpieces. Produce components for an array of industrial purposes and applications, from delicate shrouds up to large-scale trays. With the automatic tool changer and rotary part manipulator of the TruBend Center 7030, you have a completely automatic, highly productive solution for producing parts.

Equipment

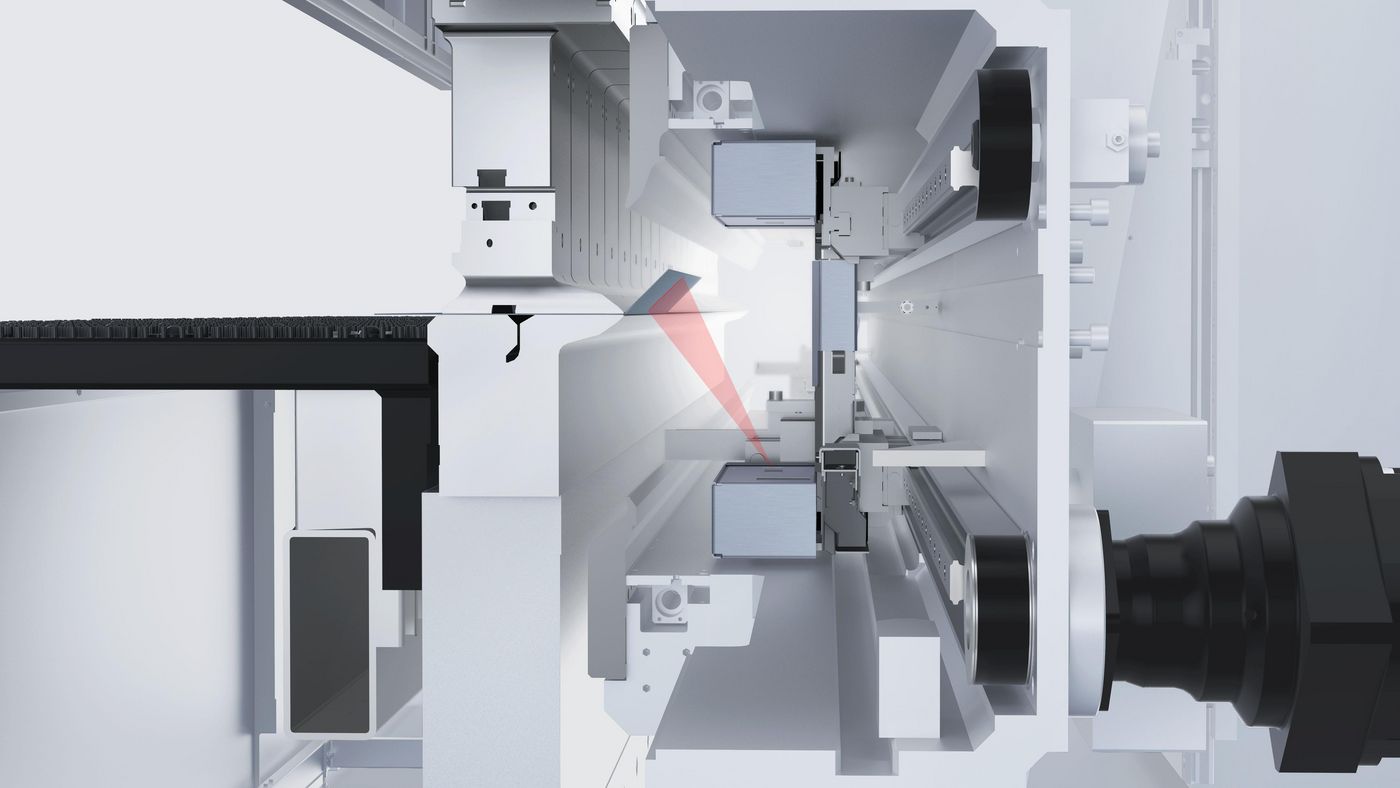

ACB laser

3-surface suction module

Magnetic/gripper module

For components with an insufficient suction area, other gripper systems take over the positioning of the sheet. For these generally smaller components, so-called magnetic or gripper modules are used.

Tools

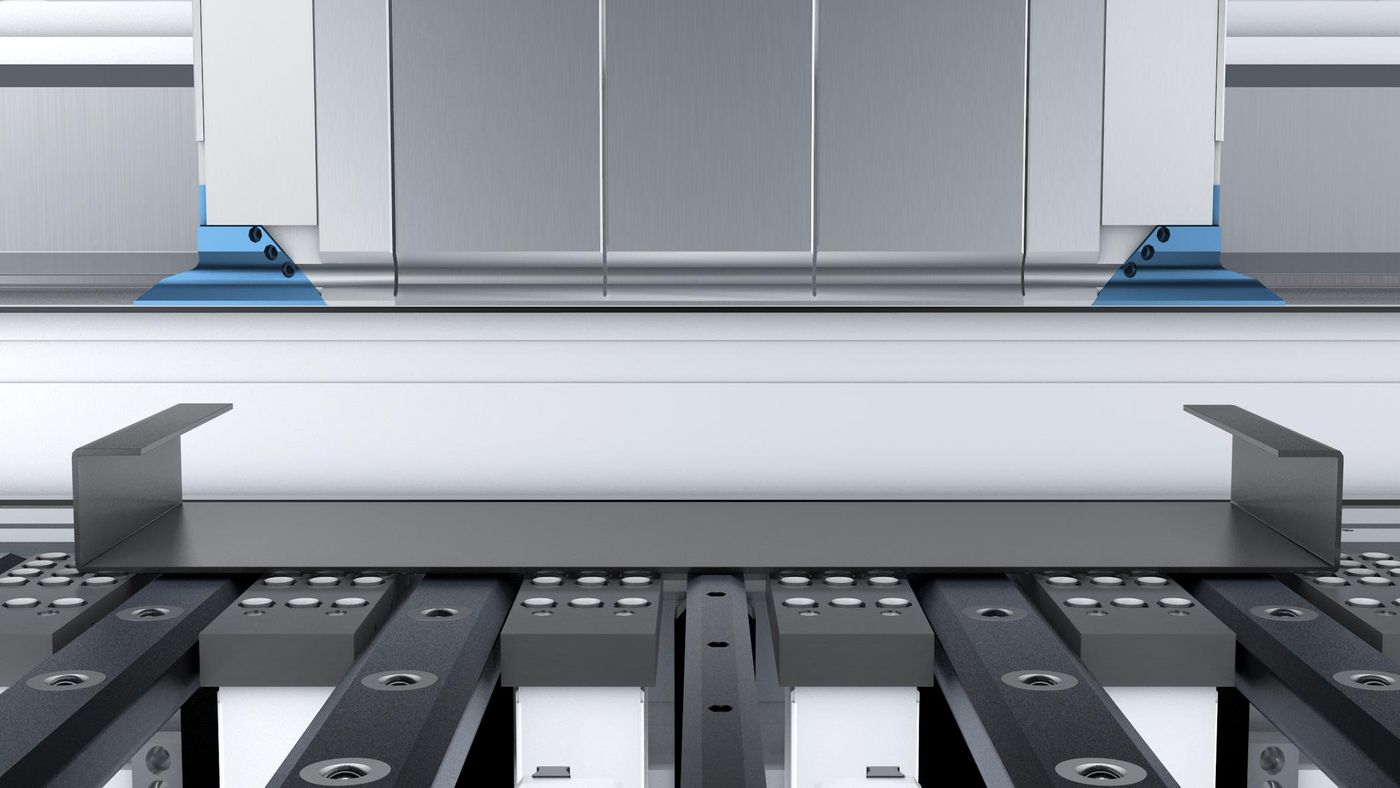

Extra blank holder tool (ENW)

Extra bending tool (ZBW)

Horn blank holder

Nestings with inner edges can be produced easily with the horn blank holders. The horn tools extend and retract automatically at an angle. This means that the upper blank holder can move downwards without causing a collision between the tool and the bend.

Send forespørsel

[contact-form-7 id="11912" title="Forespørsel"]