Produktbeskrivelse

High output with top quality

With our high-speed machines, you can bend small and medium-sized parts ergonomically and highly productively whilst saving space.

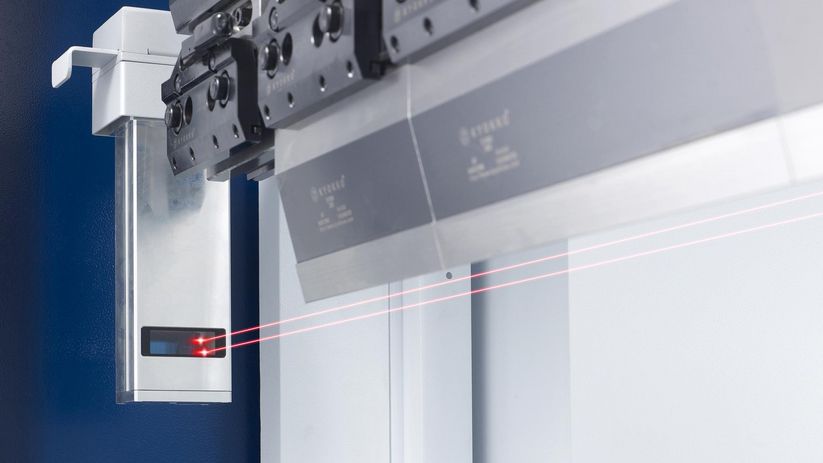

Reliable and quick

Work both safely and quickly as the BendGuard Automatic moves independently to the height of the set-up tools due to the CNC control system.

Sophisticated space saver

With its small installation area, the compact TruBend Series 7000 will fit in any production system, and can even be transported by forklift truck.

Easy to operate

The operator can work ergonomically with a standing and sitting aid. They can also adjust the support table individually.

Work ergonomically – with the TruBend Series 7000, a high value is placed on ergonomics. It was the first bending machine to have an ergonomics certificate

Equipment

Consistently ergonomic

If the bending machine operator is doing well, the bending process goes well. The TruBend Series 7000 was the first bending machine to have an ergonomics certificate. The operator can work comfortably with a standing and sitting aid. They can also adjust the support table individually. The sitting and standing aid, as well as the swiveling control, are gentle on the spine. LED lighting guarantees the best visibility in the work area.

Support consoles

With the ergonomic support consoles, you always have access to tools, blanks, or personal items.

Front work area illumination

LED technology illuminates the process area without emitting heat towards the operator.

Control that can be rotated

The control can be adjusted to the optimal inclination for working when standing or sitting. Reflections and mirroring can therefore be avoided.

Standing and sitting aid

Whether standing or sitting, the operator always has an ergonomically balanced work environment.

Comfortable support table

Even more comfortable: Depending on the lower tool height and the part geometry, the operator can adjust the arm rests to their seated position.

Two document holders

The document holders serve as storage for drawings and production documents.

Precision combined with productivity

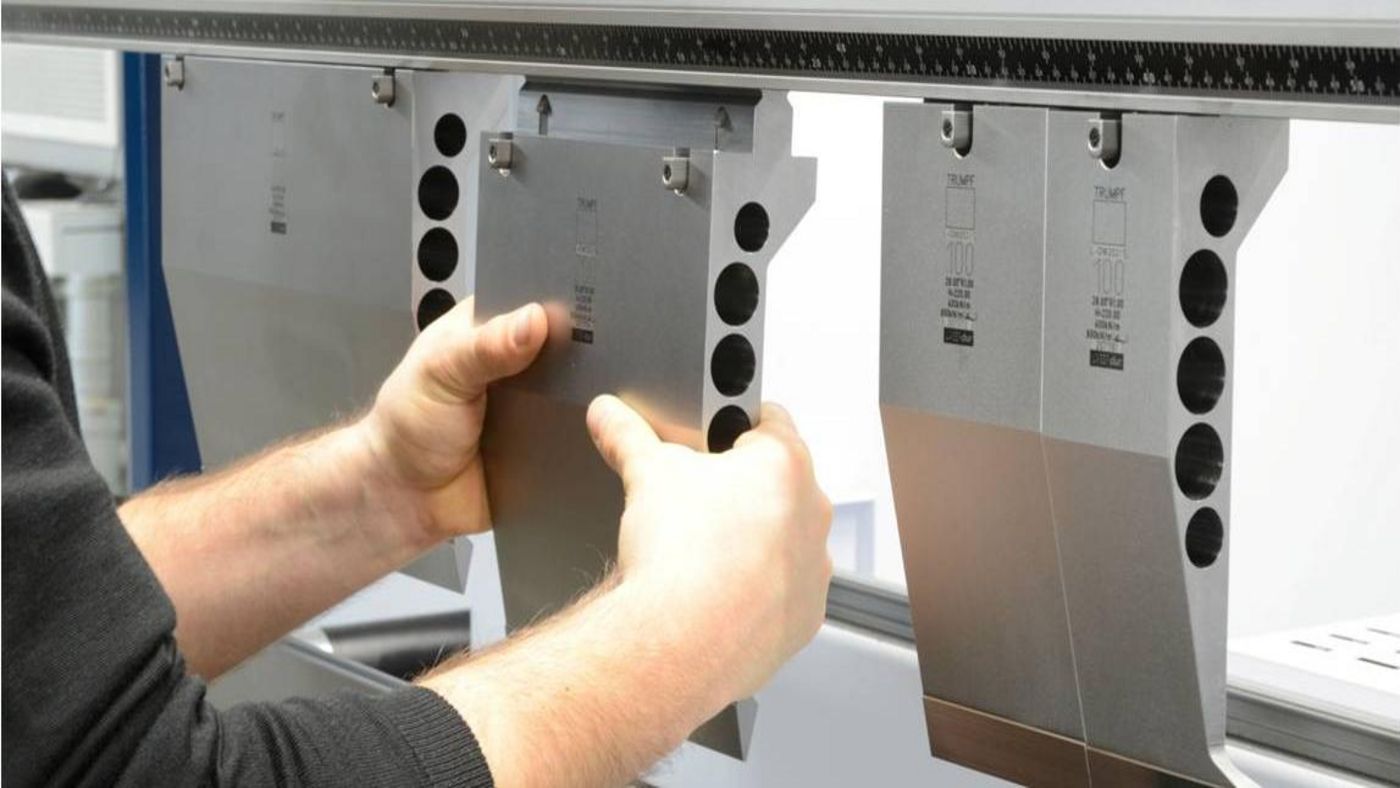

Backgauge

The 6-axis backgauge guarantees the exact positioning of your components.

ACB Wireless – a tactile process

The user-friendly ACB Wireless system measures and corrects angles using two sensor disks which are integrated in the upper tool. During bending, these sensor disks touch the inside of your bending part. In the process, together with sensors, they measure the exact angle electronically and ensure that it is perfect. The control and angle measuring system communicate wirelessly here.

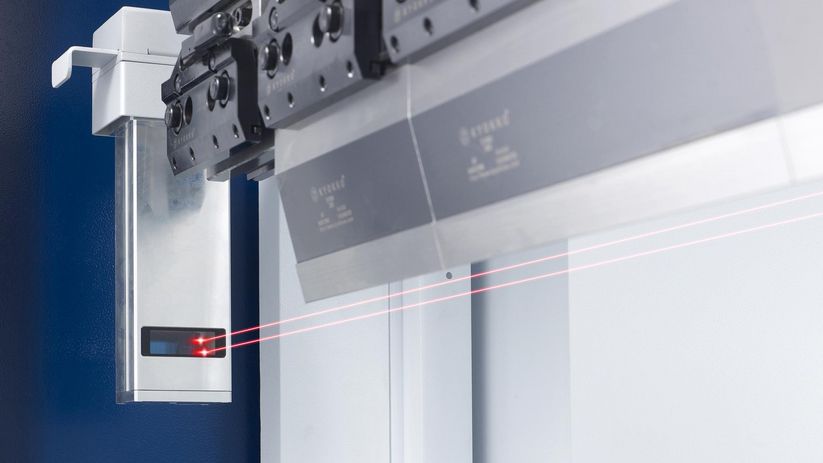

BendGuard and BendGuard Automatic

The BendGuard safety device monitors the area beneath the upper tool through a light field. Manual setting of the safety device is also a thing of the past due to BendGuard Automatic. With the help of the CNC control, BendGuard automatically moves to the height of the set-up tools. You are saved the otherwise common hand movements as well as valuable setup time, and can work safely and error free.

Touchpoint control

TruBend Touchpoint is the simple interface for operating your bending machine. Navigation follows an intuitive logic. The views are reduced to the essential items, and realistic 3D visualizations with collision check simplify processing. This means every application has the perfect solution – from simple to complex components. The integrated help also simplifies operation at the machine – it can be called up using two fingers and simple gestures such as swiping