Produktbeskrivelse

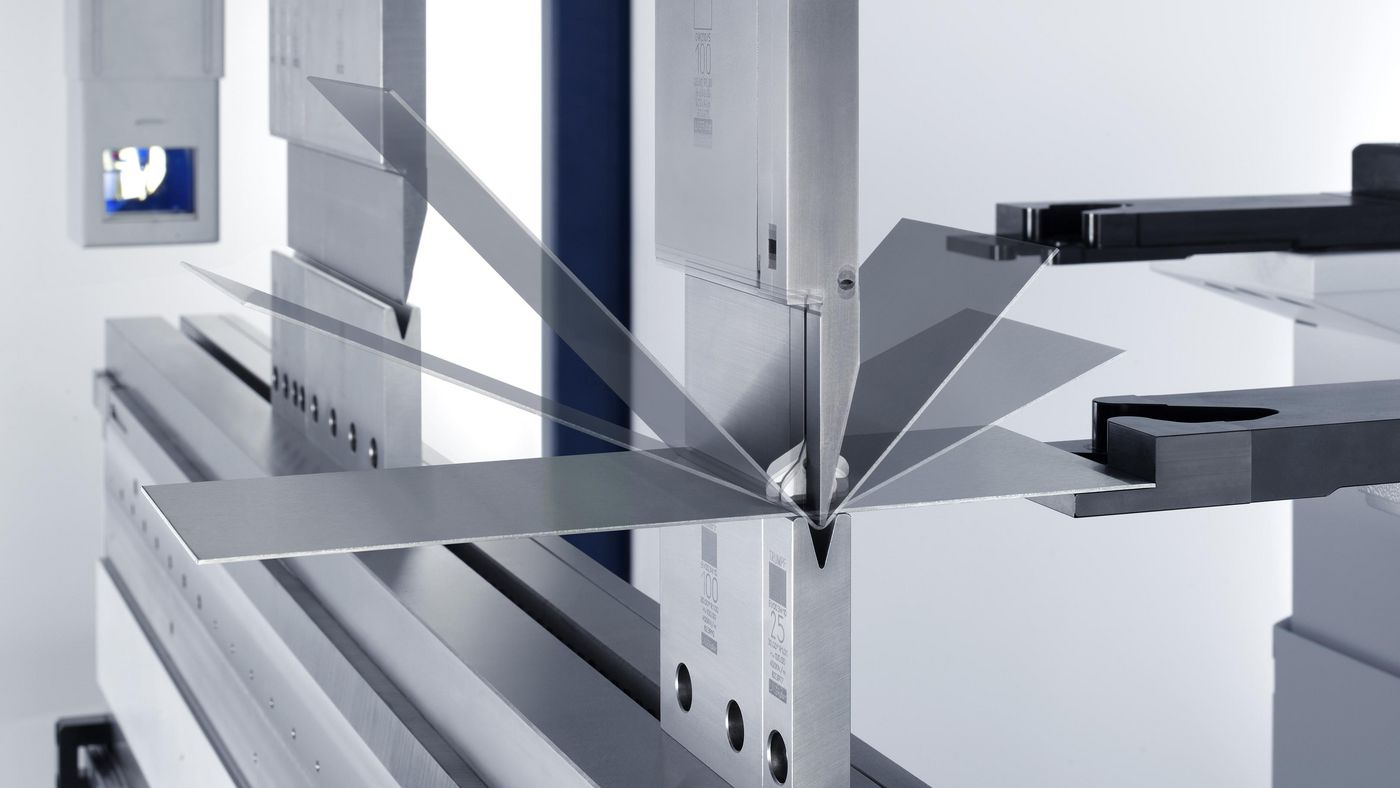

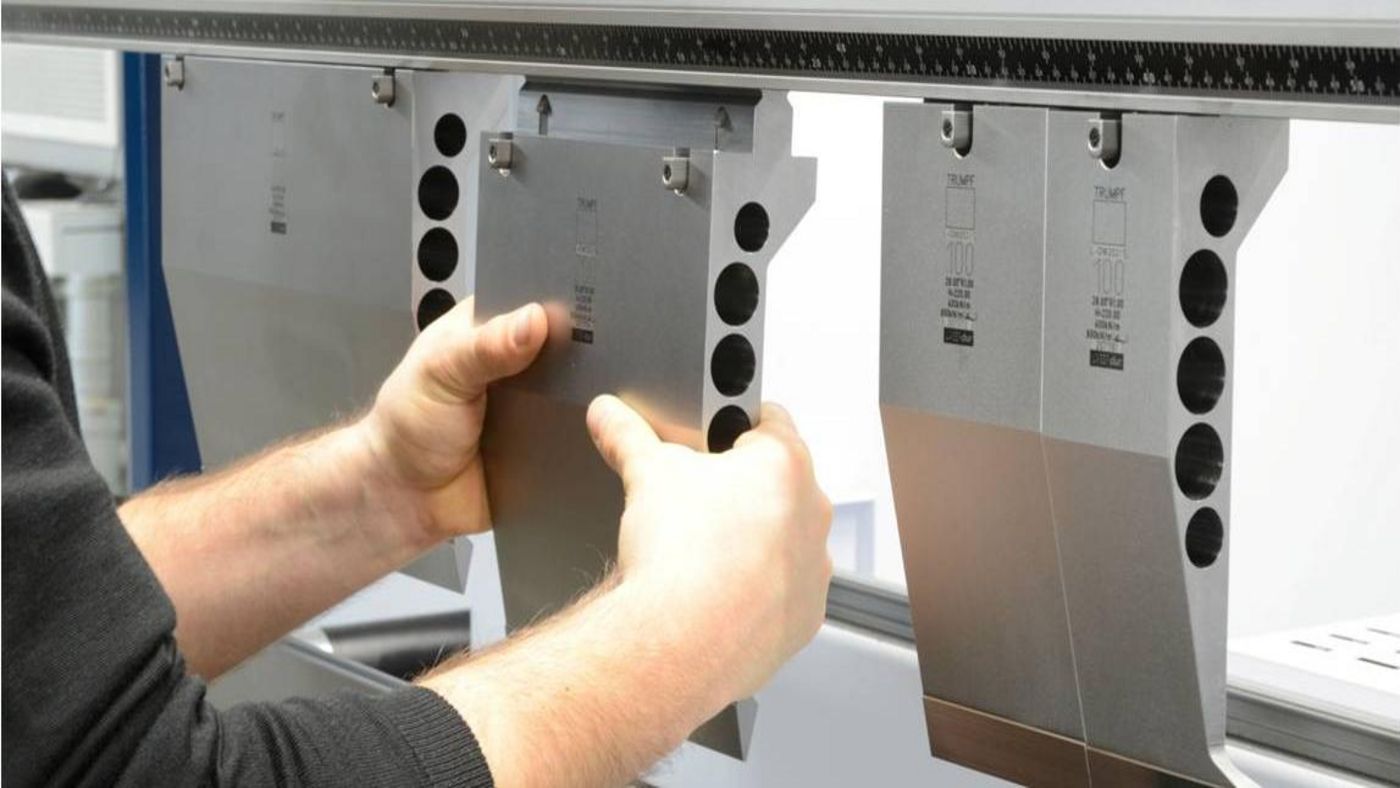

Lower tool displacement

The lower tool displacement enables special applications, such as folding.

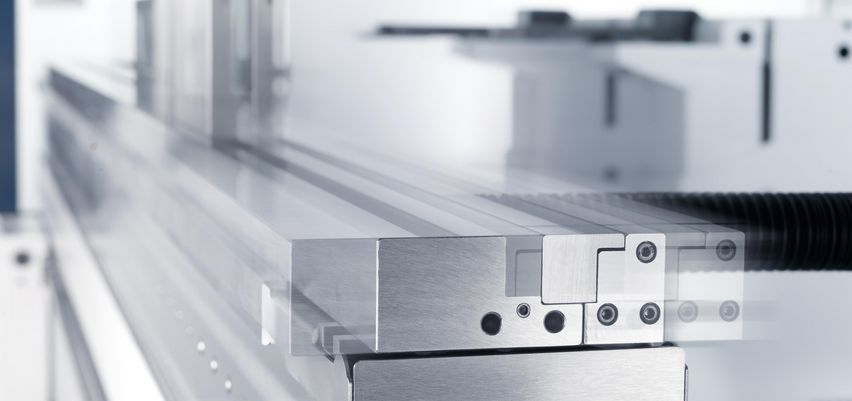

Perfect illumination with LEDs

Additional LEDs ensure perfect illumination and also prevent the generation of heat, which would be unpleasant for the operator.